In today’s world, efficient waste management has become more important than ever. Whether for industrial applications, recycling, or general waste reduction, the demand for powerful and reliable shredding machines has significantly increased. Among the various types of shredders, the Dual Shaft Shredder stands out due to its robust performance, efficiency, and versatility.

What is a Dual Shaft Shredder?

A Dual Shaft Shredder is a heavy-duty waste shredding machine designed to handle a wide variety of materials. As the name suggests, it features two parallel shafts that rotate in opposite directions. These shafts are equipped with sharp blades or cutters that pull in and cut through materials, effectively reducing their size into smaller pieces. The dual shaft design provides high torque, which is essential for shredding tough materials such as plastics, metals, rubber, paper, and more.

How Does a Dual Shaft Shredder Work?

The mechanism of a dual shaft shredder is relatively simple but highly effective. The two rotating shafts are powered by motors and are equipped with high-strength cutting blades. These shafts rotate in opposite directions, creating a “shearing” effect that helps in breaking down the materials. The materials are fed into the shredder’s hopper and are drawn in by the rotating shafts. As the shafts rotate, the material is torn and cut into smaller pieces.

The dual shaft shredder operates at a relatively slow speed but delivers high torque, making it perfect for handling hard-to-process materials. The shredder’s design ensures uniform particle size, making it ideal for further processing or recycling.

Applications of Dual Shaft Shredders

Dual shaft shredders are widely used across various industries due to their versatility and capability to handle a range of materials. Some of the most common applications include:

1. Recycling Industry

In the recycling sector, dual shaft shredders are used to process a variety of materials, including plastic, metal, and electronic waste. The shredded material can then be further processed for recycling or reuse.

2. Waste Management

Municipalities and businesses use dual shaft shredders to handle large quantities of household or industrial waste. The shredders help reduce waste volume, making it easier to transport, dispose of, or recycle the waste.

3. Plastic Processing

Plastics are notoriously difficult to recycle due to their diverse types and compositions. Dual shaft shredders can break down plastic products like bottles, containers, and film into smaller, uniform particles, making them more manageable for further processing.

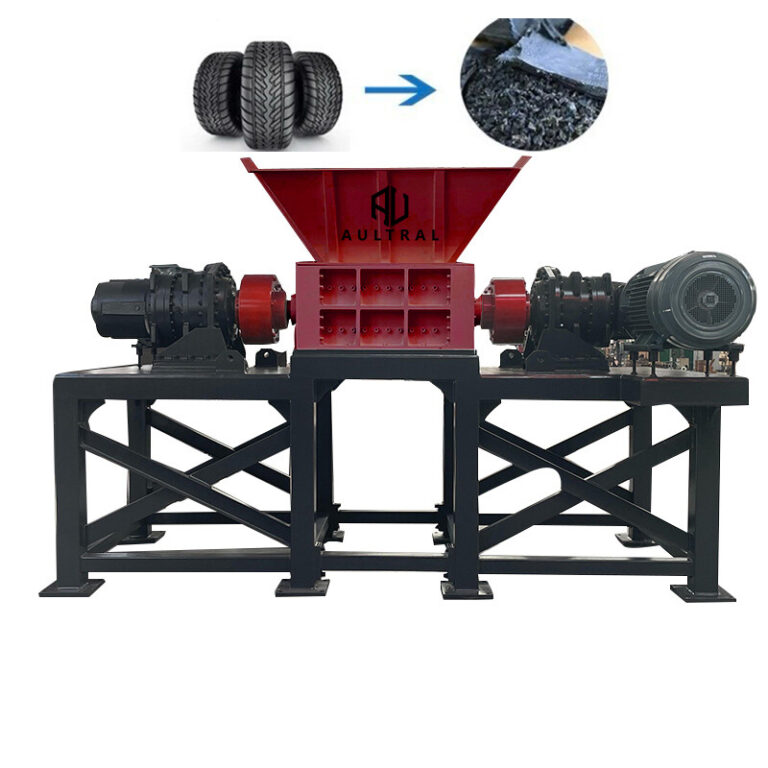

4. Tire Shredding

Tires are another material that benefits from the dual shaft shredding process. Shredding tires into smaller chunks makes it easier to repurpose them for various uses, including asphalt production or as an alternative fuel source.

5. Paper and Cardboard Shredding

Companies handling sensitive or confidential documents often use dual shaft shredders to ensure proper disposal of paper and cardboard. The resulting shredded paper can be recycled or disposed of in an environmentally friendly way.

Benefits of Dual Shaft Shredders

1. High Efficiency

Dual shaft shredders are known for their high efficiency, thanks to their powerful motors and slow-speed shredding capabilities. This efficiency reduces energy consumption while providing superior shredding performance.

2. Versatility

One of the key benefits of dual shaft shredders is their ability to handle a wide range of materials, from soft plastics to tough metals and rubber. This makes them ideal for diverse applications in industries like recycling, waste management, and manufacturing.

3. Durability

Built with heavy-duty materials, dual shaft shredders are incredibly durable and can withstand continuous operation without compromising on performance. This makes them suitable for demanding industrial environments.

4. Reduced Operational Costs

While dual shaft shredders are an investment upfront, their longevity and energy efficiency help reduce operational costs over time. They require minimal maintenance and are designed for long-term use, making them cost-effective in the long run.

5. Safety Features

Modern dual shaft shredders come with advanced safety features to protect operators. These include overload protection, emergency stop buttons, and automatic shut-off systems, ensuring a safer working environment.

Choosing the Right Dual Shaft Shredder

When selecting a dual shaft shredder, several factors should be considered:

-

Material Type: Different shredders are designed to handle specific types of materials. Make sure to choose a shredder that suits your intended application.

-

Shredding Capacity: Ensure the shredder has enough power and capacity to handle the volume of material you need to process.

-

Safety Features: Prioritize shredders that come with advanced safety mechanisms to protect operators.

-

Maintenance and Support: Choose a manufacturer or supplier that offers good after-sales support and service to ensure the longevity of your shredder.