In the world of metal fabrication, press brake machines are indispensable tools. They are used to bend and shape sheet metal with precision and force. Whether you’re forming complex parts for the automotive industry or building custom enclosures for electronics, the type of press brake you choose can make a major difference in performance, cost-efficiency, and production quality.

But with so many press brake machines available, how do you know which one suits your application? In this article, we’ll explore the different types of press brake machines, how they work, their advantages and disadvantages, and which industries benefit the most from each type.

🔧 What is a Press Brake Machine?

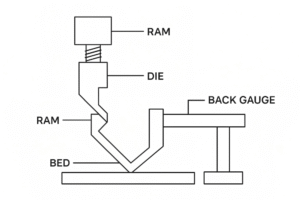

Before diving into the types, let’s first clarify what a press brake is. A press brake is a machine used for bending sheet metal by clamping the workpiece between a matching punch and die. It exerts significant force—sometimes hundreds of tons—to make accurate bends at specified angles.

The key components of a press brake include:

-

Frame: The structure that supports the system.

-

Ram or Slide: The moving part that holds the punch.

-

Bed: The fixed part where the die is placed.

-

Back gauge: Helps position the material for consistent bends.

The technology and power source behind the press brake greatly influence its capabilities and use cases. Now, let’s break down the most common types.

1. 🛠️ Mechanical Press Brakes

Mechanical press brakes operate using a flywheel mechanism that stores energy and releases it in a controlled motion to move the ram. The flywheel is connected to a crankshaft, which converts rotary motion into linear force.

✅ Advantages:

-

High-speed operation.

-

Consistent and repeatable results.

-

Ideal for long production runs with the same parts.

❌ Disadvantages:

-

Limited control during the stroke.

-

Not suitable for complex or variable jobs.

-

Requires more maintenance due to mechanical wear.

👷 Best For:

-

High-volume, simple part production.

-

Industries where speed is more important than flexibility.

2. 🔌 Hydraulic Press Brakes

These are the most common press brakes in use today. Hydraulic press brakes use hydraulic cylinders to move the ram. This provides better control over the speed, stroke length, and pressure.

✅ Advantages:

-

High precision and control.

-

Variable stroke and pressure adjustment.

-

Energy-efficient (especially modern models).

-

Can handle thicker materials.

❌ Disadvantages:

-

Slower than mechanical brakes in some cases.

-

Higher upfront cost.

-

Maintenance of hydraulic systems can be complex.

👷 Best For:

-

Shops that need versatility.

-

Applications requiring multiple bends and customizations.

-

Medium to high-volume production.

3. ⚙️ Pneumatic Press Brakes

As the name suggests, pneumatic press brakes use compressed air instead of hydraulics to generate force. They are best for lightweight bending applications.

✅ Advantages:

-

Quick operation.

-

Low initial cost.

-

Easy to maintain.

-

Environmentally friendly (no oil leaks).

❌ Disadvantages:

-

Limited force output.

-

Not suitable for thick or hard metals.

👷 Best For:

-

Light-duty applications.

-

HVAC ductwork, aluminum or thin sheet metal fabrication.

4. 🖥️ CNC Press Brakes (Computer Numerical Control)

CNC press brakes are computer-controlled hydraulic or electric press brakes. They use software and programmable controls to automate bending operations with extreme precision.

✅ Advantages:

-

High accuracy and repeatability.

-

Automated back gauges for quick setup.

-

Stores multiple programs for different jobs.

-

Reduces operator error and labor costs.

❌ Disadvantages:

-

High initial investment.

-

Requires skilled operators or training.

-

Can be overkill for simple, low-volume tasks.

👷 Best For:

-

Aerospace, automotive, precision electronics.

-

Complex parts requiring multiple bends and angles.

5. ⚡ Electric Press Brakes (Servo-Electric)

A relatively newer innovation, electric or servo-electric press brakes use electric servo motors instead of hydraulics. They are known for energy efficiency and precision.

✅ Advantages:

-

Quiet and clean operation.

-

Excellent energy efficiency.

-

High precision with low operational costs.

-

No hydraulic fluid = less maintenance.

❌ Disadvantages:

-

Limited in bending capacity for very thick metal.

-

High initial cost.

-

Not yet as widely adopted.

👷 Best For:

-

Clean environments (e.g., food or electronics industry).

-

Facilities focusing on sustainability and low energy usage.

6. 🧰 Manual Press Brakes (Hand Brakes)

Manual press brakes, also known as box and pan brakes, are operated by hand. These are small, bench-mounted or floor-standing machines suitable for basic bending tasks.

✅ Advantages:

-

Extremely low cost.

-

Simple to use.

-

Great for prototyping or custom one-offs.

❌ Disadvantages:

-

Very limited in force and capabilities.

-

Requires skilled hands for consistency.

-

Time-consuming for multiple parts.

👷 Best For:

-

Small workshops.

-

Hobbyists and custom fabricators.

🤖 Hybrid Press Brakes

Hybrid press brakes combine the speed and efficiency of electric drives with the power of hydraulics. They often use servo motors to drive hydraulic pumps, delivering a balance of performance and precision.

✅ Advantages:

-

Lower energy consumption than traditional hydraulic machines.

-

High accuracy and repeatability.

-

Environmentally friendly and quieter operation.

❌ Disadvantages:

-

Higher initial cost.

-

Still requires hydraulic maintenance (though less frequently).

👷 Best For:

-

Companies seeking to improve energy efficiency.

-

Shops needing both high force and precision.

🧮 Quick Comparison Table

| Type | Force Output | Speed | Precision | Cost | Best For |

|---|---|---|---|---|---|

| Mechanical | High | Fast | Medium | Medium | Simple, high-volume jobs |

| Hydraulic | Very High | Medium | High | High | Versatile and heavy-duty work |

| Pneumatic | Low | Fast | Low | Low | Light-duty, thin material |

| CNC | Very High | Fast | Very High | Very High | Complex, precision-driven tasks |

| Electric (Servo) | Medium | Fast | Very High | High | Clean, energy-conscious operations |

| Manual | Very Low | Slow | Medium | Very Low | Small, custom jobs |

| Hybrid | High | Fast | Very High | High | Balanced performance and savings |

🏁 Conclusion: Which Press Brake Is Right for You?

Choosing the right press brake machine depends on your production volume, material type, accuracy needs, and budget. Here’s a simple guide:

-

Just starting out? Go for a manual or pneumatic press brake.

-

Running a medium-sized fabrication shop? A hydraulic or hybrid press brake will give you the power and flexibility you need.

-

Need top-level precision for high-value parts? Invest in a CNC or electric press brake.

Each machine has its role. Understanding the differences will help you make an informed decision that boosts your productivity and ROI.

Got questions about which press brake is right for your business? 💬 Feel free to reach out—we’re here to help you bend metal the smart way!

Let me know if you want a version tailored for marketing, SEO optimization, or formatted for your blog platform.