What Is MBT (Mechanical-Biological Treatment)?

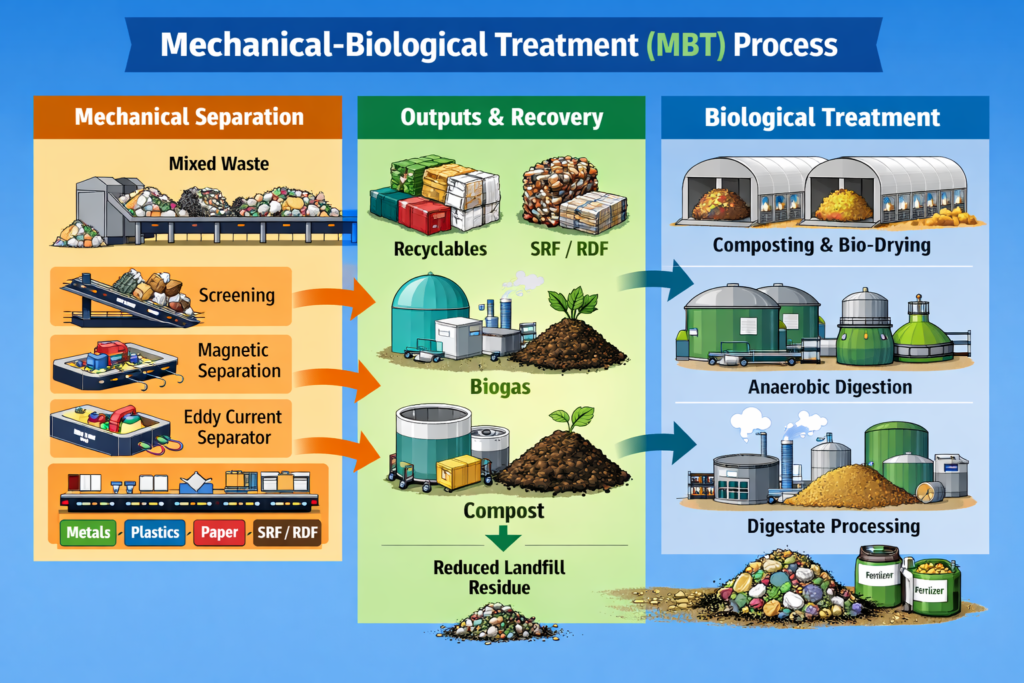

Mechanical-Biological Treatment (MBT) represents a significant evolution in sustainable waste management. It is best understood as an advanced, integrated system that combines the resource recovery capabilities of a Materials Recovery Facility (MRF) with the biological stabilization and valorization of the organic waste fraction.

While a standard MRF focuses primarily on extracting high-value recyclables (metals, plastics, paper, etc.) and often treats the separated organic waste as a residue, an MBT plant is designed to process the entire mixed waste stream with a dual mission: recovery and stabilization.

Core Objectives Of An MBT Plant

- Maximize the diversion of waste from landfill.

- Recover recyclable materials as marketable commodities.

- Biologically treat the organic fraction to reduce mass, volume, and environmental impact (odor, leachate, greenhouse gas emissions).

- Transform treated outputs into useful products such as compost, biogas, or Solid Recovered Fuel (SRF) / Refuse-Derived Fuel (RDF).

MBT is particularly crucial for regions without source separation of organic waste. It addresses wet, mixed municipal solid waste by systematically managing both the dry (recyclable) and wet (organic) components, turning a disposal problem into a resource opportunity. It is a cornerstone of zero-waste-to-landfill strategies for untreated MSW.

How Does A Mechanical-Biological Treatment System Work?

An MBT plant operates in two distinct but interconnected stages: Mechanical (M) and Biological (B). The principle is to first separate the waste mechanically and then biologically treat the organic-rich fraction.

Stage 1: Mechanical Separation And Processing (The MRF Core)

This stage resembles a dirty MRF process, optimized to prepare a high-organic feedstock for biological treatment.

Reception And Pre-Processing

Incoming mixed waste is received, and large non-processable items are removed. Bag openers liberate compacted waste.

Primary Screening

Screens (trommel, disc, or vibrating) separate fine, highly putrescible organic material and inert fines. This organic-rich undersize fraction proceeds to biological treatment.

Resource Recovery Line

The oversize fraction undergoes further separation to recover valuables:

- Ferrous Metals: Removed by magnetic separators.

- Non-Ferrous Metals: Extracted via eddy current separators.

- High-Grade Recyclables: Optical sorters (NIR / AI) recover plastics (PET, HDPE), paper, and cardboard for baling.

- High-Calorific Fraction: Remaining dry materials (mixed plastics, textiles, wood, paper) are shredded and refined into SRF / RDF.

Stage 2: Biological Treatment (The Plus In MRF+)

The organic-rich fraction from Stage 1 is biologically stabilized through one of the following pathways.

Aerobic Biological Treatment (Composting Or Bio-Drying)

Composting

Organic material is processed in windrows or enclosed tunnels. Controlled aeration enables microbial degradation, reducing volume and producing stabilized compost-like output for landscaping or landfill cover.

Bio-Drying

Airflow accelerates moisture evaporation using microbial heat. The goal is rapid drying rather than decomposition, producing a stable, high-calorific fraction suitable for SRF / RDF.

Anaerobic Digestion (AD)

Organic slurry is processed in oxygen-free digesters. Microorganisms generate biogas (methane and CO₂), which is used for electricity and heat generation. Digestate is further composted or used as a soil amendment.

Final Outputs Of An MBT Plant

- Recyclable materials

- SRF / RDF

- Biogas and compost

- Minimal inert residue for landfill

Key Equipment And Installations In An MBT Plant

An MBT facility integrates advanced mechanical sorting equipment with specialized biological treatment systems.

Mechanical Separation Line Equipment

- Bag Openers

- Trommel, Disc, Or Vibrating Screens

- Magnetic Separators

- Eddy Current Separators

- Optical Sorters (NIR, AI)

- Ballistic Separators

- Shredders

- Baling Presses

Equipment is heavy-duty to handle mixed waste, with screen sizes optimized for organic unders and fuel-rich overs.

Biological Treatment Installations

For Aerobic Treatment

- Enclosed Bio-Halls

- Windrow Turners

- Aerated Static Pile Or Tunnel Systems

- Biofilters For Odor Control

For Anaerobic Digestion

- Pre-Treatment And Pulpification Units

- Digester Tanks (Vertical Or Horizontal)

- Biogas Storage And CHP Units

- Digestate Dewatering And Processing Systems

Why Choose Aultral For Your MBT Project?

Designing an MBT plant requires precise integration of mechanical and biological processes. Aultral provides turnkey MBT solutions backed by decades of waste characterization experience.

Our global waste composition database enables accurate prediction of organic content, moisture, C/N ratio, and biodegradability, allowing precise biological process design.

We deliver fully integrated engineering. Mechanical pre-treatment is designed specifically to optimize downstream composting or anaerobic digestion performance, maximizing biogas yield, compost stability, or SRF quality.

Our MBT systems are modular and future-proof, allowing phased upgrades such as adding anaerobic digestion or adjusting SRF production according to market demand.

MBT Solutions: Integrated Pathways For Maximum Resource Recovery

Each MBT project is engineered to match local regulations, waste composition, and economic objectives.

Material And Organic Recovery MBT

Focuses on high-purity recyclables and stabilized compost production using intensive mechanical sorting and enclosed aerobic composting.

Energy And Material Recovery MBT (With AD)

Combines recyclable recovery with anaerobic digestion to maximize renewable energy generation and greenhouse gas reduction.

SRF Production And Stabilization MBT

Optimizes production of high-calorific, low-chlorine SRF for industrial fuel substitution. Bio-drying stabilizes wet organics and boosts overall fuel yield.

At Aultral, we conduct detailed feasibility studies to ensure every waste fraction is upgraded from disposal to material, energy, or fuel recovery.

Economic And Environmental Benefits Of MBT Systems

Beyond technical performance, Mechanical-Biological Treatment delivers strong economic and environmental returns, making it a strategic investment for municipalities and private operators alike.

From an economic perspective, MBT significantly reduces landfill dependency. By stabilizing organic waste and recovering recyclables and SRF, landfill disposal volumes can be reduced by 60–80%, translating directly into lower tipping fees, extended landfill life, and reduced long-term environmental liabilities. In regions with rising landfill taxes or landfill bans on untreated waste, MBT often becomes the most cost-effective compliance solution.

Revenue streams are diversified. Recovered metals and plastics generate direct sales income, SRF provides an alternative fuel for cement kilns and power plants, and biogas from anaerobic digestion offsets grid electricity or produces renewable energy credits. This multi-output model reduces financial risk compared to single-purpose waste facilities.

Environmentally, MBT plays a critical role in climate mitigation. Biological stabilization drastically cuts methane emissions that would otherwise occur in landfills. Anaerobic digestion further converts organic waste into renewable energy, replacing fossil fuels and lowering overall carbon intensity. Odor, leachate, and vector impacts are also tightly controlled through enclosed processing and engineered air treatment systems.

Design Considerations For A Successful MBT Project

No two waste streams are identical. Successful MBT plants are built on accurate waste characterization and realistic operational assumptions.

Key design parameters include organic fraction percentage, moisture content, seasonal variability, calorific value, contamination levels, and local market demand for recyclables, compost, SRF, or energy. Oversizing mechanical equipment or underestimating biological retention time can severely impact performance and operating costs.

Equally important is regulatory alignment. Compost quality standards, SRF specifications, emissions limits, and renewable energy incentives vary widely by region. An MBT design must anticipate not only current regulations but also future tightening of environmental standards.

Operational simplicity and robustness are essential. MBT plants handle heterogeneous, often unpredictable waste. Equipment selection, redundancy, and automation levels must balance performance with ease of maintenance and local skill availability.

The Role Of MBT In Circular Economy And Urban Sustainability

MBT is no longer just a waste treatment solution; it is a foundational infrastructure for the circular economy.

By converting mixed municipal waste into secondary raw materials, renewable energy, and alternative fuels, MBT closes material loops that were previously lost to disposal. Cities implementing MBT systems gain resilience against resource scarcity, energy volatility, and landfill constraints.

For rapidly urbanizing regions and developing economies where source separation remains challenging, MBT provides an immediate, scalable pathway toward modern waste management without waiting for perfect household sorting behavior.

MBT bridges the gap between today’s waste reality and tomorrow’s zero-waste ambition.

Partner With Aultral For Long-Term MBT Success

At Aultral, we view MBT not as a standard plant, but as a customized system engineered for performance, compliance, and long-term value.

From feasibility studies and process simulation to equipment manufacturing, installation, and commissioning, we support the entire project lifecycle. Our focus is not just on building plants, but on ensuring stable operation, predictable outputs, and measurable environmental impact.

Mechanical-Biological Treatment is the future of integrated waste management—and with the right partner, it becomes a powerful engine for sustainability, energy recovery, and economic return.