In the field of scrap metal recycling and steel processing, hydraulic gantry shears have become essential equipment for handling large and heavy scrap materials. Among them, the Hydraulic Gantry Shear Model 315T stands out for its cutting efficiency, reliability, and adaptability to a wide range of industrial applications. This article introduces the working principle, advantages, applications, and technical parameters of this powerful machine.

What Is a Hydraulic Gantry Shear?

A hydraulic gantry shear is a large-scale metal cutting machine designed to shear heavy scrap steel, H-beams, plates, pipes, and other oversized materials. It adopts a gantry frame structure with a vertically descending cutting blade, powered by a hydraulic system that provides immense shearing force. Compared with other types of metal shears, the gantry design ensures higher stability, precise cutting, and long service life even under continuous heavy load.

The machine is widely used in scrap recycling yards, steel mills, ship dismantling sites, and metal processing plants. It plays a key role in reducing the size of scrap materials, improving storage efficiency, and preparing the metal for smelting or further processing.

Main Features of the Hydraulic Gantry Shear (315T Model)

The 315T Hydraulic Gantry Shear is built for tough cutting jobs. It combines power and precision, offering a compact structure with easy maintenance and excellent performance. Below are its key features:

-

High Shearing Force:

With a rated pressure of 315 tons, this machine can easily cut through thick steel plates, beams, and heavy metal scrap. -

Sturdy Gantry Frame:

The frame is made of high-strength welded steel to ensure rigidity and stability during the shearing process, reducing vibration and improving accuracy. -

Efficient Hydraulic System:

The hydraulic system uses reliable components to provide consistent pressure and smooth operation, ensuring long-term stability and low noise. -

Simple Operation:

Equipped with a PLC control system or manual operation mode, the gantry shear can be easily adjusted to meet different working requirements. -

Automatic Feeding and Cutting Options:

Depending on the configuration, it can work with conveyor belts or cranes to achieve semi-automatic or fully automatic operation, increasing productivity. -

Easy Maintenance and Long Service Life:

All wear-resistant parts, such as blades and guide rails, are made from high-quality materials that can withstand years of heavy-duty use.

Technical Parameters of Hydraulic Gantry Shear Model 315T

| Model | 315T Hydraulic Gantry Shear |

|---|---|

| Shearing Force | 315 Tons |

| Blade Length | 1200 mm |

| Shearing Frequency | 6–10 times/min |

| Maximum Cutting Thickness | Up to 40 mm steel plate |

| Main Motor Power | 37 kW |

| Hydraulic System Pressure | 25 MPa |

| Machine Weight | About 12 Tons |

| Dimension (L×W×H) | 3000 × 1200 × 2200 mm |

| Operation Mode | Manual or PLC Control |

| Cooling Method | Air or Water Cooling (optional) |

| Power Supply | 380V/50Hz (Customizable) |

These parameters may vary slightly depending on customer requirements, as Shanghai Aultral Machinery Co., Ltd. can customize the machine based on material type, cutting thickness, and production capacity.

Applications of the Hydraulic Gantry Shear

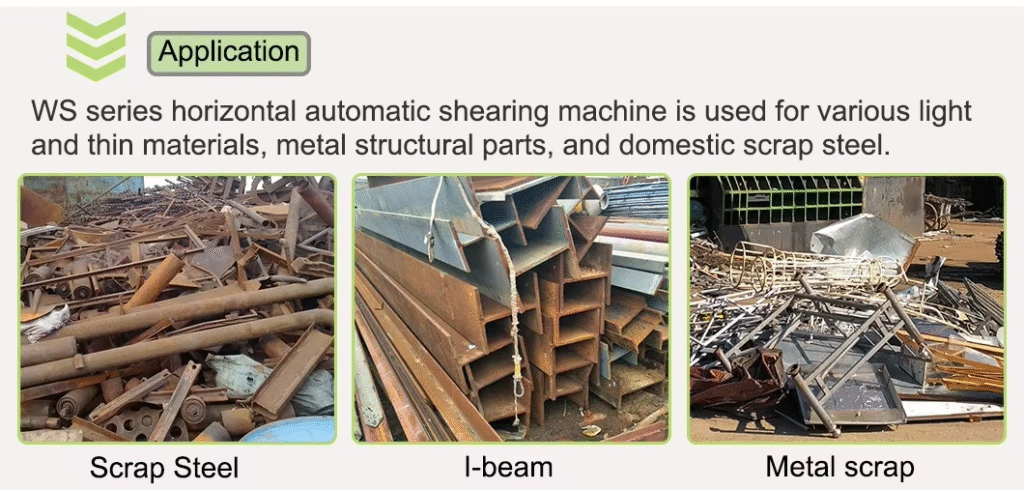

The 315T hydraulic gantry shear is suitable for a wide range of materials and industries, including:

-

Scrap Steel Recycling: Cutting scrap steel bars, plates, and beams into uniform pieces for melting.

-

Ship and Car Dismantling: Efficiently cutting large metal structures for secondary processing.

-

Steel Mills: Handling leftover steel plates and production waste.

-

Construction Waste Recycling: Processing rebars, angle steel, and other metal debris.

-

Manufacturing Plants: Managing metal offcuts and scrap for recycling.

With its high shearing force and strong frame design, the 315T model performs well even in continuous heavy-duty working environments.

Why Choose a Hydraulic Gantry Shear?

Compared to traditional mechanical shears or alligator shears, hydraulic gantry shears offer several advantages:

-

Higher Cutting Force: Capable of cutting thicker and larger metal pieces.

-

Stable and Safe Operation: The gantry frame design ensures balanced force and operator safety.

-

Energy Efficiency: The hydraulic system saves energy and delivers consistent performance.

-

Lower Maintenance Costs: Fewer moving parts reduce wear and tear, ensuring long-term stability.

-

Customization Options: Adjustable blade length, power, and control systems to suit specific needs.

These benefits make the gantry shear one of the most cost-effective and practical machines in the recycling and metal processing industry.

Maintenance Tips for Better Performance

To ensure long service life and stable operation, users should follow these maintenance guidelines:

-

Check Hydraulic Oil Regularly: Maintain clean oil and replace it periodically.

-

Inspect Blades: Keep blades sharp and replace them if they become worn or chipped.

-

Lubricate Moving Parts: Apply grease to joints and bearings to reduce friction.

-

Monitor Hydraulic System: Check for leaks or abnormal pressure fluctuations.

-

Clean Working Area: Prevent debris accumulation near the cutting area.

Routine maintenance ensures the machine operates safely and efficiently for years.

The Hydraulic Gantry Shear Model 315T is a reliable and efficient solution for cutting heavy scrap metal and steel materials. With its robust frame, powerful hydraulic system, and user-friendly operation, it is ideal for recycling centers, metal processing plants, and demolition sites.