In the modern scrap metal recycling industry, efficiency, safety, and cutting power are critical factors. Among various metal processing machines, the hydraulic gantry shear stands out as one of the most powerful and reliable solutions for cutting large and heavy scrap materials. Designed for high-intensity industrial applications, hydraulic gantry shears are widely used in steel mills, recycling plants, and metal processing centers around the world.

What Is a Hydraulic Gantry Shear?

A hydraulic gantry shear is a heavy-duty metal cutting machine that uses hydraulic power to shear large scrap metal into smaller, manageable sizes. It is typically equipped with a strong gantry frame, a movable shear blade, and a hydraulic system that delivers extremely high cutting force.

Unlike alligator shears or smaller hydraulic shearing machines, gantry shears are specifically designed for oversized and thick materials, such as scrap steel plates, beams, ship scrap, structural steel, and bundled metal waste.

How Does a Hydraulic Gantry Shear Work?

The working principle of a hydraulic gantry shear is based on high-pressure hydraulic cylinders. Scrap metal is placed on the feeding table or directly into the cutting area. The gantry-mounted blade moves vertically or horizontally under hydraulic force, applying tremendous pressure to cut the metal cleanly.

Key components include:

-

Heavy-duty gantry structure

-

High-strength alloy steel blades

-

Hydraulic cylinders and pumps

-

Electrical control system (manual or automatic)

This structure ensures stable operation, precise cutting, and long service life even under continuous heavy workloads.

Key Advantages of Hydraulic Gantry Shears

1. Extremely High Cutting Force

Hydraulic gantry shears are capable of handling thick and dense metal materials that cannot be processed by ordinary shears. Cutting forces can reach hundreds or even thousands of tons, depending on the model.

2. High Efficiency for Large-Scale Recycling

With large feeding openings and powerful shearing capability, gantry shears significantly improve processing efficiency. They are ideal for recycling yards that handle high volumes of scrap metal daily.

3. Versatile Material Handling

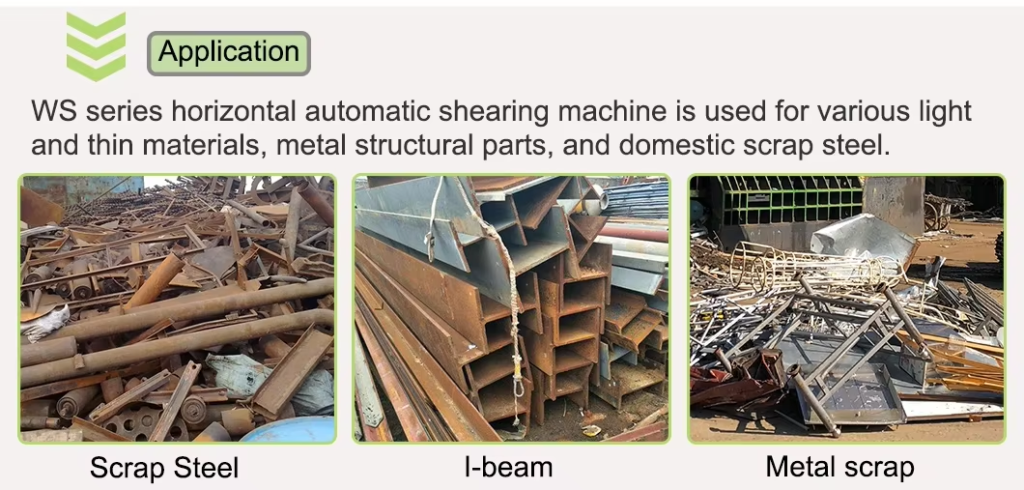

A hydraulic gantry shear can cut:

-

Scrap steel plates

-

H-beams and I-beams

-

Ship dismantling scrap

-

Steel pipes and profiles

-

Compressed scrap bundles

This versatility makes it a core machine in comprehensive scrap recycling lines.

4. Durable and Long-Lasting Design

Built with reinforced steel frames and wear-resistant blades, hydraulic gantry shears are designed for long-term industrial use with minimal downtime and maintenance.

5. Safer Operation

Compared with flame cutting or manual cutting methods, hydraulic gantry shears provide a safer working environment. Many modern machines are equipped with remote control systems and safety protection devices.

Common Applications of Hydraulic Gantry Shears

Hydraulic gantry shears are widely used in:

-

Scrap metal recycling plants

-

Steel mills and foundries

-

Shipbreaking yards

-

Metal fabrication factories

-

Waste processing and resource recovery centers

They are often combined with hydraulic balers, shredders, and crushers to form a complete metal recycling production line.

Hydraulic Gantry Shear vs. Other Shearing Machines

Compared with alligator shears or box shears, hydraulic gantry shears offer:

-

Larger cutting capacity

-

Higher automation potential

-

Better suitability for oversized scrap

-

Higher initial investment but greater long-term productivity

For large-scale operations, the hydraulic gantry shear is often the most cost-effective solution over time.

Key Factors to Consider When Choosing a Hydraulic Gantry Shear

When selecting the right hydraulic gantry shear, buyers should consider:

-

Cutting force and blade size

-

Maximum material thickness and length

-

Feeding method (manual, conveyor, crane feeding)

-

Automation level and control system

-

Power supply and hydraulic system quality

Choosing a reliable manufacturer with strong technical support is also crucial for long-term performance.

Future Trends in Hydraulic Gantry Shear Technology

With increasing environmental regulations and demand for efficient recycling, hydraulic gantry shears are evolving toward:

-

Higher automation and intelligent control

-

Energy-saving hydraulic systems

-

Integration with smart recycling lines

-

Improved safety and remote operation features

These advancements make hydraulic gantry shears even more essential in modern scrap metal processing.

The hydraulic gantry shear is a powerful, efficient, and reliable machine for heavy scrap metal cutting. Its high cutting force, wide application range, and durable design make it an indispensable piece of equipment for large-scale metal recycling operations. For businesses seeking to improve productivity, reduce labor costs, and enhance safety, investing in a high-quality hydraulic gantry shear is a smart and future-proof decision.