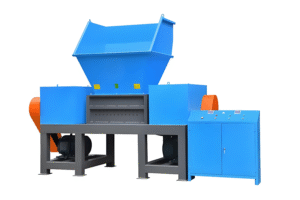

In the fast-evolving world of recycling and waste management, dual-shaft shredders have emerged as an essential solution for processing complex and bulky materials. Whether you’re dealing with plastic, metal, rubber, or industrial waste, a dual-shaft shredder provides the power and flexibility to meet diverse shredding requirements. This article explores the core functions, key advantages, and wide-ranging applications of this versatile machine.

🔧 What Is a Dual-Shaft Shredder?

A dual-shaft shredder, also known as a two-shaft shredder, is a low-speed, high-torque shredding machine equipped with two parallel shafts fitted with cutting blades. These blades rotate in opposite directions to tear, shear, and crush materials into smaller, manageable sizes. Unlike high-speed crushers, dual-shaft shredders prioritize durability, torque, and precision, making them ideal for demanding applications.

⚙️ Key Features and Functional Benefits

-

Powerful Motor Drive

Equipped with two high-torque motors (e.g., 7.5kW × 2), the shredder ensures stable operation under heavy loads. -

Variable Speed Control

With speeds ranging from 8–20 RPM, it offers controlled material shredding with minimal dust and noise. -

Customizable Blade Thickness

Blade thickness options from 15mm to 40mm allow optimization based on the hardness and size of materials. -

Robust Feeding System

A spacious feeding box (e.g., 700×650mm) accommodates large items without pre-cutting. -

Low Maintenance

Designed with simple mechanical structures and high wear-resistance components to reduce downtime.

🔄 What Materials Can It Shred?

The dual-shaft shredder is engineered for versatile waste processing, and is commonly used in industries such as recycling, manufacturing, construction, and municipal waste management. Typical shreddable materials include:

-

🟢 Plastic: HDPE pipes, PET bottles, packaging waste

-

🟠 Metal: Aluminum profiles, scrap steel, copper sheets

-

🔴 Rubber: Tires, rubber blocks, insulation waste

-

⚪ Wood: Pallets, crates, furniture scraps

-

🟡 Fabric/Cotton Wool: Textiles, waste cloth, soft industrial waste

💼 Industrial Applications

-

Recycling Plants – For pre-processing waste before granulation or melting

-

Metal Recovery Facilities – For downsizing scrap to improve melting efficiency

-

E-Waste Processing – For safe dismantling of electronics

-

Municipal Solid Waste Centers – For bulky waste and mixed material reduction

-

Manufacturing Sites – For managing offcuts, rejects, and packaging residue

🌍 Environmental and Operational Advantages

By reducing material size and volume, dual-shaft shredders not only optimize transportation and storage but also enhance recycling efficiency. This leads to:

-

Lower waste disposal costs

-

Reduced carbon footprint

-

Improved safety and cleanliness in the workplace

💡 Why Choose Aultral’s Dual-Shaft Shredder?

At Shanghai Aultral Machinery Co., Ltd., we design our dual-shaft shredders with industrial-grade strength, modular blade configurations, and customizable feeding systems. With a FOB Shanghai price starting at just USD 7,500, our shredder is a smart investment for businesses seeking efficiency, durability, and sustainability.

Ready to upgrade your recycling line?

Contact us today to get a quote, product demo, and expert consultation tailored to your needs.