As the global scrap metal recycling industry continues to expand, efficiency, mobility, and cutting performance have become key factors in equipment selection. Traditional stationary cutting systems often require fixed infrastructure and high installation costs. In contrast, a mobile gantry shear offers a flexible, high-performance solution for on-site scrap metal cutting and processing.

What Is a Mobile Gantry Shear?

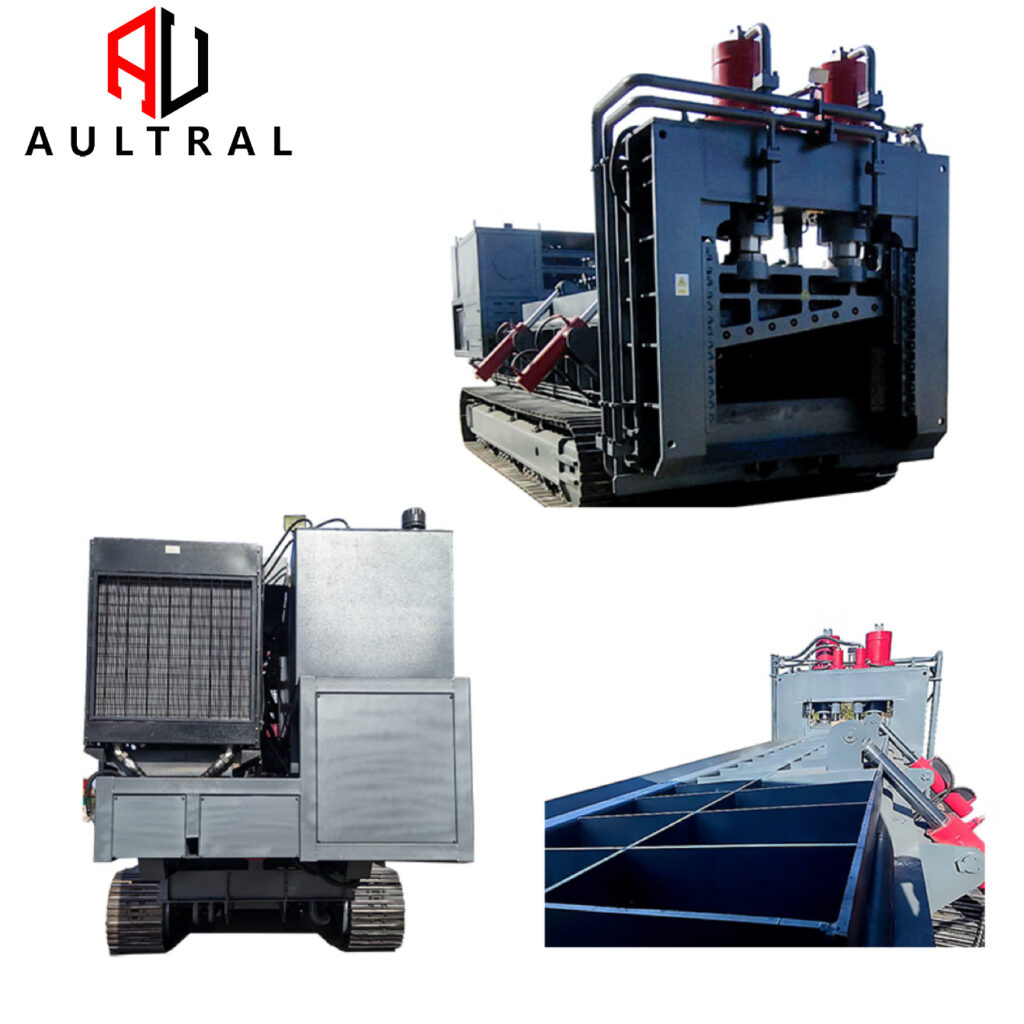

A mobile gantry shear is a heavy-duty hydraulic cutting machine designed to shear large and bulky scrap metal. Unlike stationary gantry shears, mobile models are mounted on wheels or crawler tracks, allowing them to be easily transported and operated at different job sites.

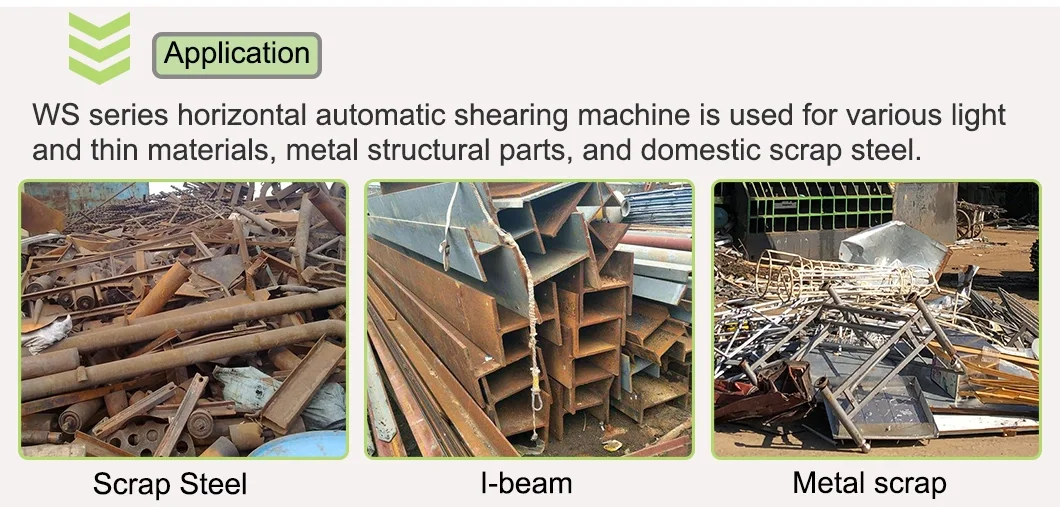

Mobile gantry shears are widely used in scrap yards, demolition sites, ship recycling, and steel processing plants where flexibility and high cutting capacity are required. They are capable of cutting steel plates, beams, pipes, rebar, and mixed scrap into manageable sizes for further processing or smelting.

How Does a Mobile Gantry Shear Work?

The working principle of a mobile gantry shear is based on hydraulic cutting power combined with a gantry-style frame:

-

Scrap Feeding

Scrap metal is placed into the cutting area using an excavator, crane, or loader. -

Positioning and Clamping

The gantry structure allows precise positioning of the scrap material. Some models include hydraulic clamping devices to hold the material firmly. -

Hydraulic Shearing

A powerful hydraulic cylinder drives the cutting blade downward, applying strong shear force to cut the metal cleanly and efficiently. -

Material Discharge

The cut pieces are easily collected for transportation, baling, or further recycling processes.

This process ensures high cutting efficiency with minimal material loss.

Key Advantages of Mobile Gantry Shears

1. High Mobility and Flexibility

The biggest advantage of a mobile gantry shear is its mobility. Mounted on wheels or crawler tracks, it can be quickly moved between different work areas or job sites, reducing transportation costs for raw scrap.

2. Powerful Cutting Performance

Mobile gantry shears are equipped with high-pressure hydraulic systems, delivering strong cutting force capable of handling thick steel and heavy scrap materials.

3. On-Site Processing Efficiency

By cutting scrap metal directly at the source, mobile gantry shears reduce the need for transporting oversized materials, improving overall operational efficiency.

4. Reduced Infrastructure Requirements

Unlike fixed gantry shears, mobile models require minimal civil construction and installation, making them ideal for temporary sites or expanding scrap yards.

5. Durable Industrial Design

Built with heavy-duty steel frames, wear-resistant blades, and reliable hydraulic components, mobile gantry shears are designed for long-term, high-intensity operation.

Applications of Mobile Gantry Shears

Mobile gantry shears are widely used across various industries, including:

-

Scrap metal recycling yards

-

Steel mills and foundries

-

Demolition and construction sites

-

Shipbreaking and offshore recycling

-

Automotive dismantling facilities

-

Large industrial manufacturing plants

They are suitable for cutting:

-

Steel plates and sheets

-

H-beams and I-beams

-

Pipes and tubes

-

Rebar and structural steel

-

Mixed heavy scrap metal

Mobile vs. Stationary Gantry Shear

While stationary gantry shears are ideal for fixed, high-volume recycling plants, mobile gantry shears provide greater flexibility. Mobile models are especially suitable for operations that require frequent relocation or on-site cutting. For businesses handling scrap from multiple locations, a mobile gantry shear can significantly reduce logistics and handling costs.

How to Choose the Right Mobile Gantry Shear

When selecting a mobile gantry shear, consider the following key factors:

-

Cutting Capacity

Check the maximum thickness and size of metal the machine can shear. -

Shearing Force

Higher tonnage ensures efficient cutting of thick and hard materials. -

Mobility Type

Choose between wheeled or crawler-mounted designs based on site conditions. -

Power System

Diesel engine, electric motor, or hybrid power options should match your operating environment. -

Blade Quality and Maintenance

High-quality, replaceable blades reduce downtime and operating costs. -

Manufacturer Support and Certification

Select a supplier with proven experience, CE certification, and reliable after-sales service.

Why Invest in a Mobile Gantry Shear?

A mobile gantry shear is more than just a cutting machine—it is a strategic investment for modern scrap metal recycling operations. By improving on-site processing, reducing transportation costs, and increasing overall productivity, it helps businesses remain competitive in a demanding market.

With rising environmental regulations and growing demand for recycled steel, efficient and flexible metal cutting solutions are essential for sustainable development.

A mobile gantry shear offers a powerful combination of mobility, cutting efficiency, and durability for scrap metal recycling and demolition applications. Its ability to process heavy scrap on-site makes it an ideal solution for businesses seeking flexibility and cost savings.