In today’s fast-paced industrial and recycling environments, managing scrap metal effectively is crucial for maximizing operational efficiency and environmental sustainability. One essential piece of equipment that has become increasingly popular across scrap yards, recycling centers, and metal processing facilities is the horizontal scrap metal baler machine.

What is a Horizontal Scrap Metal Baler Machine?

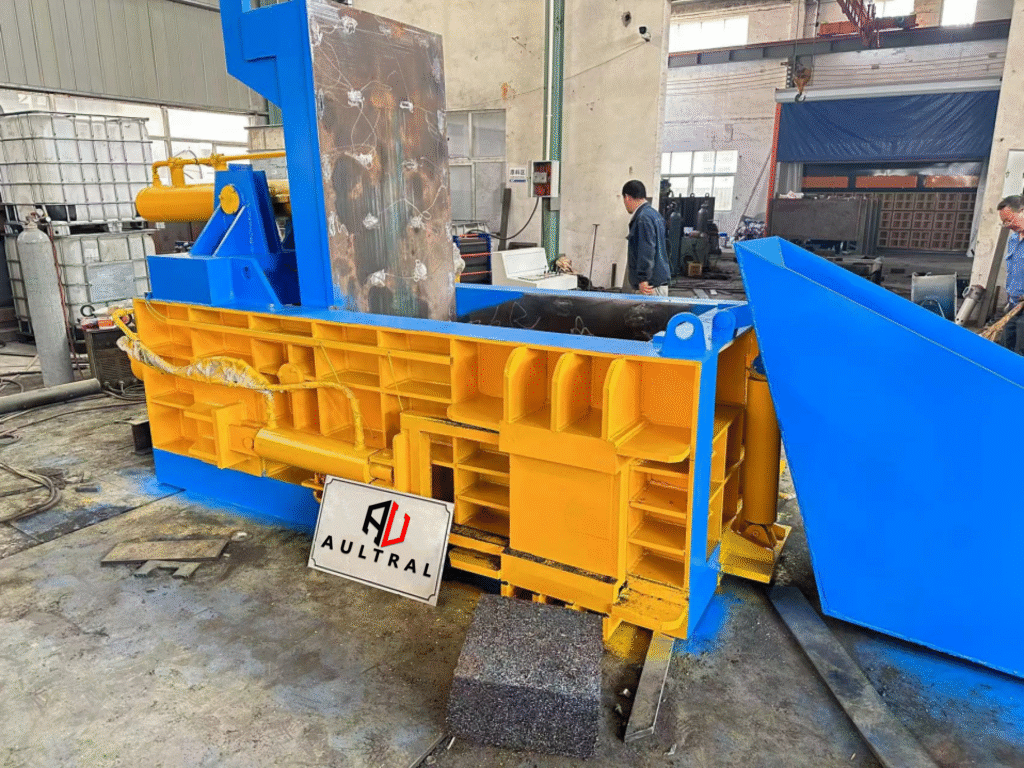

A horizontal scrap metal baler machine is a hydraulic-powered device designed to compress various types of metal waste—such as steel, aluminum, and copper—into dense, manageable bales. Unlike vertical balers, which compress materials from top to bottom, horizontal balers operate from the sides. This allows for faster processing, higher output, and continuous feeding, making them ideal for high-volume operations.

Key Features and Benefits

1. High Efficiency and Throughput

One of the major advantages of using a horizontal scrap metal baler machine is its ability to handle large volumes of scrap in a short amount of time. The horizontal feed design allows for automatic or semi-automatic operation, reducing manual labor and improving processing speed. This makes it especially useful in facilities dealing with consistent and heavy scrap metal loads.

2. Compact and Uniform Bales

By applying powerful hydraulic pressure, the machine compresses loose and bulky scrap into uniform bales. These bales are easier to store, transport, and resell. Compact bales also save storage space and reduce transportation costs, increasing overall profitability for scrap dealers and recyclers.

3. Durable Construction

Horizontal scrap metal balers are built with heavy-duty steel frames and wear-resistant components. Their robust design ensures long-term durability and reliable performance even in harsh industrial environments. Many models also include safety features and advanced control systems to protect operators and equipment.

4. Eco-Friendly Operation

Using a horizontal scrap metal baler machine supports sustainable practices. By compressing and recycling metal waste, businesses can reduce their environmental footprint, minimize landfill use, and contribute to the circular economy. Efficient recycling also lowers the demand for raw material extraction, which helps conserve natural resources.

Applications of Horizontal Scrap Metal Balers

These machines are widely used in various industries, including:

-

Scrap Metal Recycling Yards – To compact loose scrap for easier transport and resale.

-

Manufacturing Plants – To manage production waste and metal offcuts efficiently.

-

Demolition and Construction Sites – To process leftover structural steel, pipes, and rebar.

-

Automotive Industry – For compressing car body parts, engine components, and other metal scraps.

Choosing the Right Machine

When selecting a horizontal scrap metal baler machine, consider factors like:

-

Bale size and weight requirements

-

Type and volume of metal to be processed

-

Automation level (manual, semi-auto, or fully automatic)

-

Available space and installation requirements

It’s also important to work with reputable manufacturers who offer customized solutions, reliable after-sales service, and durable machinery that complies with safety standards.

A horizontal scrap metal baler machine is a valuable investment for any business involved in metal recycling or processing. With its high efficiency, strong compression capabilities, and environmentally friendly design, it plays a vital role in optimizing scrap handling operations. By integrating this powerful machine into your workflow, you can improve productivity, reduce costs, and make a positive impact on the environment.