In the modern recycling industry, the demand for efficient, space-saving, and cost-effective waste management solutions has never been higher. Whether you’re handling paper, cardboard, plastics, or textiles, having the right equipment can make a significant difference in productivity and operational costs. One such game-changing machine is the single cylinder vertical baler. Designed for compacting recyclable materials into dense bales, this baler has become an essential tool for many businesses involved in waste management and recycling.

In this article, we’ll explore the features, benefits, and applications of the single cylinder vertical baler, as well as why it’s an excellent investment for businesses looking to improve efficiency and sustainability.

What is a Single Cylinder Vertical Baler?

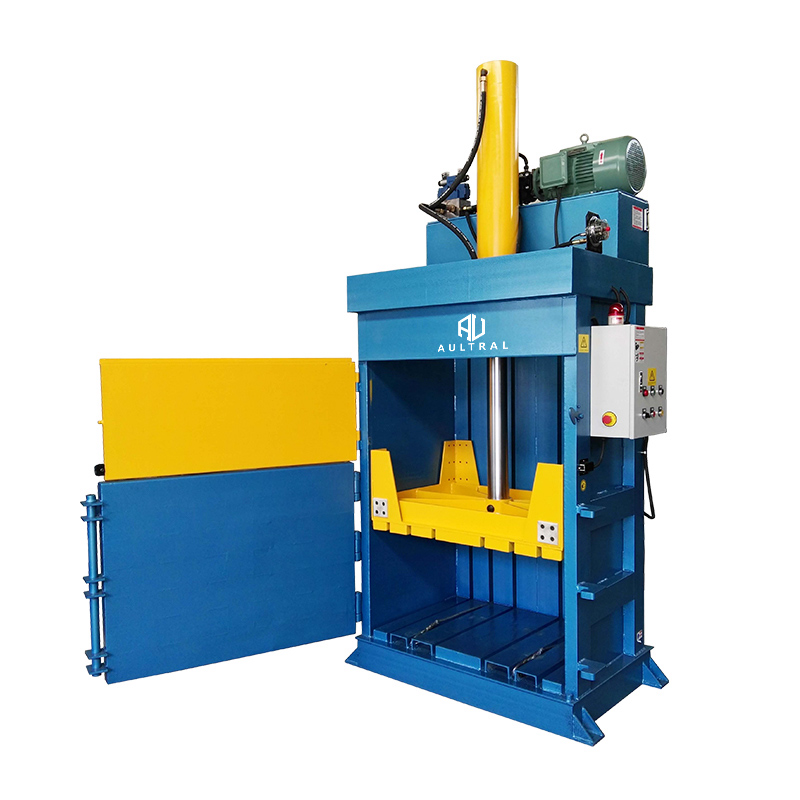

A single cylinder vertical baler is a hydraulic machine used to compress waste materials such as cardboard, paper, plastic, and other recyclable materials into tightly bound bales. Unlike other balers that might have multiple cylinders, the single cylinder version uses one hydraulic piston to apply pressure on the material. This design not only simplifies the operation but also reduces the need for complicated mechanisms, making it more cost-effective and easier to maintain.

The vertical design of the baler means that materials are loaded from the top, and the bale is ejected from the bottom. This setup makes it particularly useful in environments where space is limited. Once the material is loaded into the chamber, the hydraulic pressure is applied to compress it into a compact bundle, which is then securely tied and ready for transport or recycling.

How Does a Single Cylinder Vertical Baler Work?

The operation of a single cylinder vertical baler is straightforward and efficient. Here’s a quick breakdown of how it works:

-

Loading: Materials such as cardboard, paper, or plastics are loaded into the machine through the top opening.

-

Compression: The hydraulic system activates the single cylinder, pushing a ram down onto the material. This compression reduces the volume of waste by up to 90%, turning it into dense, manageable bales.

-

Tying: Once the bale has reached the desired size, the baler’s automatic or manual tying system secures the bale using wire or plastic straps.

-

Ejection: The finished bale is ejected from the bottom of the machine, ready for transport or further processing.

This streamlined process helps reduce labor costs, improve efficiency, and increase overall productivity in recycling operations.

Key Benefits of a Single Cylinder Vertical Baler

-

Space Efficiency

One of the biggest advantages of a single cylinder vertical baler is its compact design. Its vertical orientation allows it to take up less floor space, making it ideal for facilities with limited room. Businesses in urban areas or smaller facilities can benefit greatly from this space-saving feature. -

Cost-Effective Operation

Due to its simple design, a single cylinder vertical baler typically costs less to maintain compared to more complex machines with multiple cylinders. Additionally, it uses less power and requires fewer parts, which can significantly reduce both upfront costs and long-term operational expenses. -

High Bale Density

The hydraulic pressure applied by the single cylinder creates compact, high-density bales, which helps optimize storage and reduce transportation costs. The tighter the bale, the more material can be packed into a shipping container or storage space, improving overall efficiency. -

Easy to Use and Maintain

With its user-friendly interface and simple hydraulic operation, a single cylinder vertical baler is easy for operators to use with minimal training. The fewer components mean there’s less chance for mechanical failure, and maintenance is typically quicker and more straightforward. -

Environmentally Friendly

By compacting waste into manageable bales, this baler helps to reduce the environmental impact of waste disposal. Recycling the material in these bales reduces landfill usage, lowers emissions associated with transportation, and promotes a more sustainable recycling process.

Applications of a Single Cylinder Vertical Baler

The single cylinder vertical baler is versatile and can be used in a variety of industries. Here are some common applications:

-

Recycling Facilities: Ideal for processing materials like paper, cardboard, plastics, and textiles, a vertical baler helps to increase the efficiency of recycling operations by creating easily transportable bales.

-

Retail and Supermarkets: Retail businesses often generate large amounts of cardboard waste. A vertical baler can help quickly and efficiently process cardboard for recycling, reducing waste management costs.

-

Manufacturing Plants: Many manufacturing facilities generate significant amounts of waste, including scrap paper, plastic, and textiles. A single cylinder vertical baler helps to compact these materials for easier disposal or recycling.

-

Distribution Centers: Warehouses and distribution centers dealing with packaging materials such as paper and plastic can greatly benefit from the space-saving and time-saving features of a vertical baler.

Why Choose a Single Cylinder Vertical Baler?

If you’re in the business of managing waste or running a recycling facility, a single cylinder vertical baler can offer a range of benefits, including increased operational efficiency, reduced labor costs, and improved space utilization. Here are some reasons why it’s a smart choice for your business:

-

Compact and Space-Efficient: Its vertical design helps businesses with limited floor space to process high volumes of waste without taking up too much room.

-

Cost-Effective and Reliable: The simplicity of the single cylinder mechanism reduces both initial investment and maintenance costs, while offering reliable and consistent performance.

-

Environmental Impact: The baler helps you reduce waste and promote recycling, making it a valuable tool for companies committed to sustainability.

The single cylinder vertical baler is a powerful, cost-effective, and space-saving solution for businesses involved in waste management and recycling. Its efficient operation, low maintenance requirements, and ability to produce high-density bales make it an excellent choice for a wide range of industries. Whether you’re managing a large recycling facility or a smaller retail operation, investing in a single cylinder vertical baler can help you optimize your waste management processes, reduce costs, and contribute to a more sustainable future.