🔍 Introduction: The Rising Need for Smarter Waste Management

As businesses around the globe face mounting pressure to reduce environmental impact and improve operational efficiency, vertical balers have stepped into the spotlight. These compact, user-friendly machines are ideal for handling recyclable materials in small to medium-sized facilities where space, labor, and budget are limited.

But where exactly are vertical balers being used? What is driving their adoption? And why are they becoming an increasingly important tool in modern waste management strategies?

Let’s dive into the key application scenarios, market analysis, and future outlook for vertical baling machines.

🏭 Real-World Applications of Vertical Balers

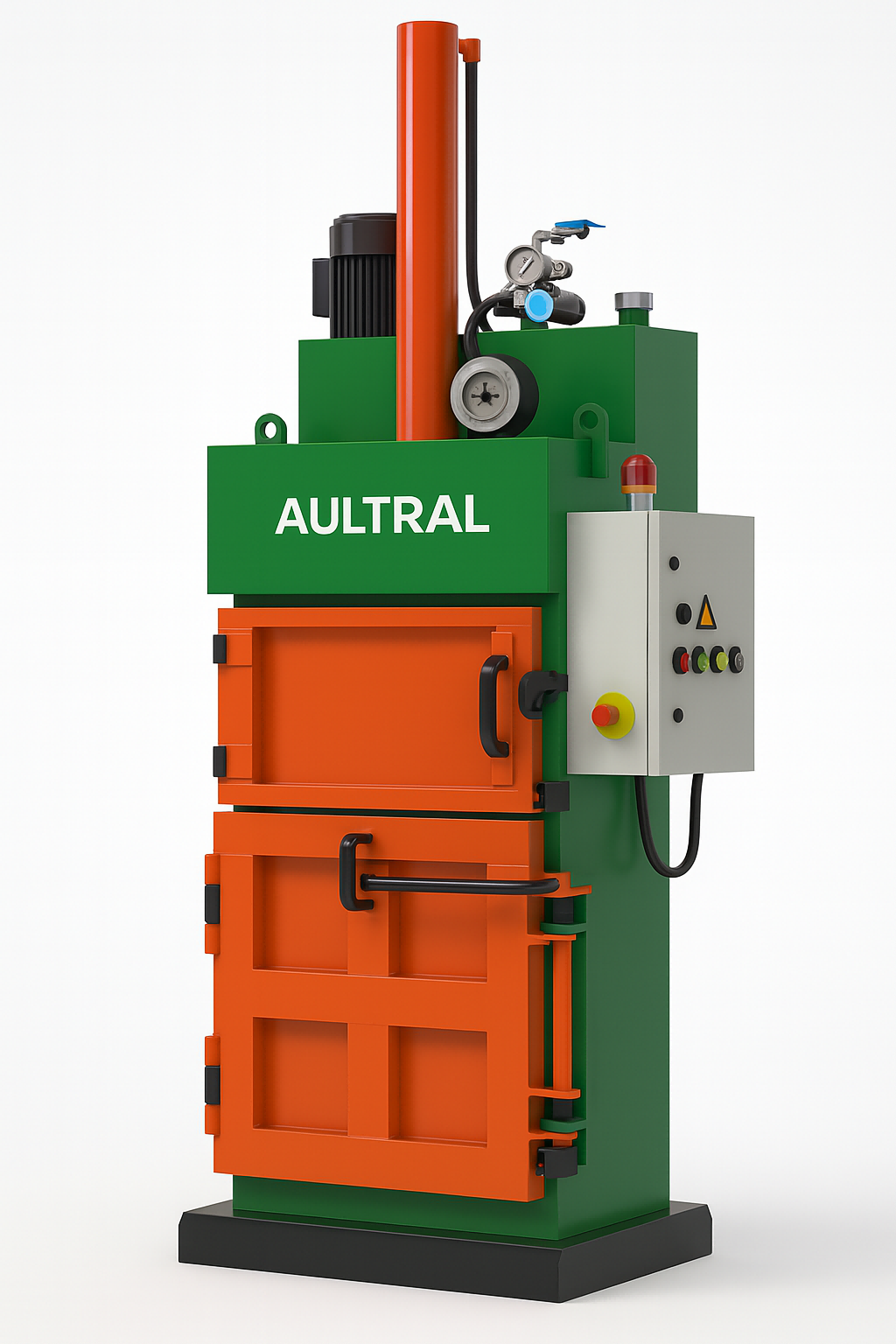

Vertical balers are versatile machines designed to compress recyclable materials like cardboard, plastic, textiles, and paper into dense, manageable bales. Their vertical design makes them space-efficient and easy to operate.

1. Retail Chains & Supermarkets

These businesses generate a high volume of packaging materials—cardboard boxes, stretch film, and plastic wrap. A vertical baler allows them to:

-

Reduce floor clutter

-

Lower waste collection frequency

-

Sell compacted cardboard to recycling companies

Case Example: A regional supermarket chain in Europe reported a 40% reduction in waste management costs after installing vertical balers across 20 locations.

2. Garment & Textile Industries

Used clothing exporters and textile manufacturers use vertical balers to pack:

-

Old clothes for export

-

Fabric waste and cotton for recycling

-

Uniforms and linens for disposal

Bonus Benefit: Many models feature lifting doors or rear ejection, speeding up the packing process.

3. Plastic Recycling Plants

Vertical balers efficiently handle:

-

PET bottles

-

Shrink wrap

-

Thin plastic sheets

These balers reduce bulk volume by up to 80%, significantly cutting transportation costs.

4. Offices, Warehouses & Logistics Centers

With increasing e-commerce activity, packaging waste is piling up in storage and fulfillment centers. Vertical balers are used to:

-

Compact cardboard boxes

-

Bale shredded documents

-

Streamline internal logistics

5. Hospitality & Healthcare

Hotels and hospitals benefit from vertical balers to compress:

-

Laundry waste

-

Food packaging

-

Non-hazardous plastic and paper

This enhances hygiene and reduces waste disposal frequency in sensitive environments.

📊 Market Outlook: Why Demand for Vertical Balers is Growing

The vertical baler market is expanding rapidly—and here’s why:

✅ Environmental Regulations

Governments in the EU, US, and Asia are enforcing stricter waste disposal standards. Businesses are encouraged or required to sort and recycle materials more efficiently. Vertical balers help meet compliance goals.

📦 Packaging Waste Explosion

The e-commerce boom has led to an explosion in cardboard and plastic waste. Companies need compacting solutions that are:

-

Affordable

-

Easy to install

-

Scalable with operations

🏗️ Small Footprint, Big Impact

Unlike horizontal balers, vertical models have a compact footprint, making them perfect for small factories, shops, and warehouses with limited space.

📉 Low Operating Costs

With lower investment and minimal training required, vertical balers provide a high ROI for small and medium businesses.

Market Forecast: According to a report by Market Research Future, the global vertical baler market is expected to grow at 5.2% CAGR through 2030, with Asia-Pacific leading the way due to urbanization and industrial growth.

🛠 Product Spotlight: What Makes a Good Vertical Baler?

When choosing a vertical baler, consider:

-

Hydraulic cylinder diameter (affects pressure and compaction ratio)

-

Motor power (commonly 7.5kW to 15kW)

-

Bale size & weight (sized to fit your logistics needs)

-

Applicable materials (plastic bottles, clothes, cardboard, etc.)

-

Discharge method (manual, lifting door, or rear ejection)

A high-performance model typically offers:

-

Stable operation

-

Strong structure

-

Easy maintenance

-

Low noise design

🌍 The Future: Opportunities in Circular Economy and Waste Valorization

As industries move toward the circular economy, vertical balers play a key role in the “first mile” of recycling. They enable waste materials to be:

-

Sorted

-

Compressed

-

Transported for reprocessing

From developing nations looking to modernize waste collection, to advanced economies optimizing warehouse automation—vertical balers are a scalable, adaptable tool for the future.

🤝 Final Thoughts: A Practical Solution for Real-World Challenges

Whether you’re running a retail chain, operating a textile recycling business, or managing waste in a commercial facility, vertical balers provide a cost-effective, sustainable, and reliable solution.

💬 What Do You Think?

Is your business currently maximizing its waste handling efficiency? Could a vertical baler reduce your labor, space, and transport costs?

We’d love to hear your experience or needs—leave a comment or message us directly for tailored advice.