In today’s world, where environmental concerns and waste management are increasingly critical, businesses and industries are seeking efficient solutions to handle and recycle waste materials. The single-cylinder vertical baler has emerged as a highly effective and cost-efficient machine for compressing and compacting various types of waste, particularly for materials like plastics, cardboard, textiles, and metals. This baler is widely used in recycling plants, warehouses, and manufacturing facilities, offering a range of benefits to companies looking to optimize their waste handling processes.

What is a Single Cylinder Vertical Baler?

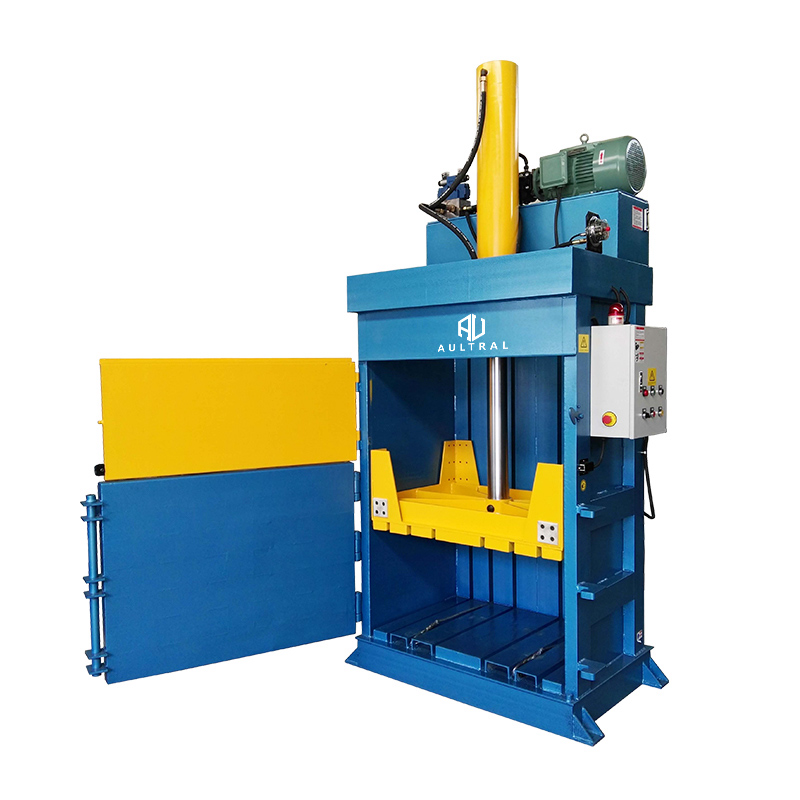

A single-cylinder vertical baler is a hydraulic-powered machine designed to compress waste materials into compact bales. The machine’s design allows for vertical compression, utilizing a single hydraulic cylinder to exert pressure on the waste materials. This system is efficient, reliable, and highly effective in creating dense, uniform bales that are easy to handle, store, and transport. Unlike other balers, the vertical design saves space, making it ideal for facilities with limited floor area.

Key Features and Benefits of the Single Cylinder Vertical Baler

1. Space-Efficient Design

The vertical structure of the baler means it requires significantly less floor space compared to horizontal balers. This makes it ideal for businesses with limited space, allowing them to process large amounts of waste without needing a large footprint. The compact design helps maximize the use of available space while still providing high performance.

2. Energy-Efficient Operation

With its single hydraulic cylinder, the vertical baler offers an energy-efficient operation. The machine is designed to consume minimal power while achieving maximum compression, reducing electricity costs for businesses. It provides a cost-effective solution for companies looking to improve their waste management systems without high operational costs.

3. High Compression Efficiency

Single-cylinder vertical balers are known for their high compression efficiency. By compressing materials tightly into dense bales, they minimize storage space requirements and make transportation more economical. This increased compression not only reduces waste volume but also helps reduce the environmental impact by making recycling processes more effective.

4. Versatility

These balers are highly versatile and can handle a wide range of waste materials. Whether it’s cardboard, paper, plastics, or textiles, the single-cylinder vertical baler can efficiently compress these materials into manageable bales. This versatility makes it a great choice for a variety of industries, from retail to manufacturing and recycling.

5. Easy to Operate and Maintain

With simple controls and user-friendly design, the single-cylinder vertical baler is easy to operate, even for operators with minimal training. The machine is designed with durability in mind, requiring minimal maintenance. Regular checks and basic maintenance will keep the baler running smoothly, making it a long-term investment for businesses.

Applications of the Single Cylinder Vertical Baler

1. Recycling Plants

Recycling centers use vertical balers to efficiently process large volumes of waste materials, such as cardboard, plastic, and metal. The ability to create dense, compact bales helps reduce storage space and makes transportation more cost-effective.

2. Retail and Wholesale Industries

Retailers and wholesalers generate a significant amount of packaging waste, such as cardboard and plastic. A vertical baler provides an efficient way to manage this waste, ensuring it is compacted for recycling and reducing the environmental footprint of the business.

3. Manufacturing Facilities

Manufacturing companies often deal with scrap materials like metal, plastic, and paper. The single-cylinder vertical baler helps in compressing these materials into bales that are easier to store, recycle, and transport, thus improving overall waste management operations.

The single-cylinder vertical baler is a highly effective machine for managing and recycling waste materials across various industries. With its space-saving design, energy efficiency, and high compression capability, it offers an optimal solution for businesses looking to reduce waste and optimize their recycling processes. By investing in this machine, companies can enhance their operational efficiency, reduce costs, and contribute to environmental sustainability.