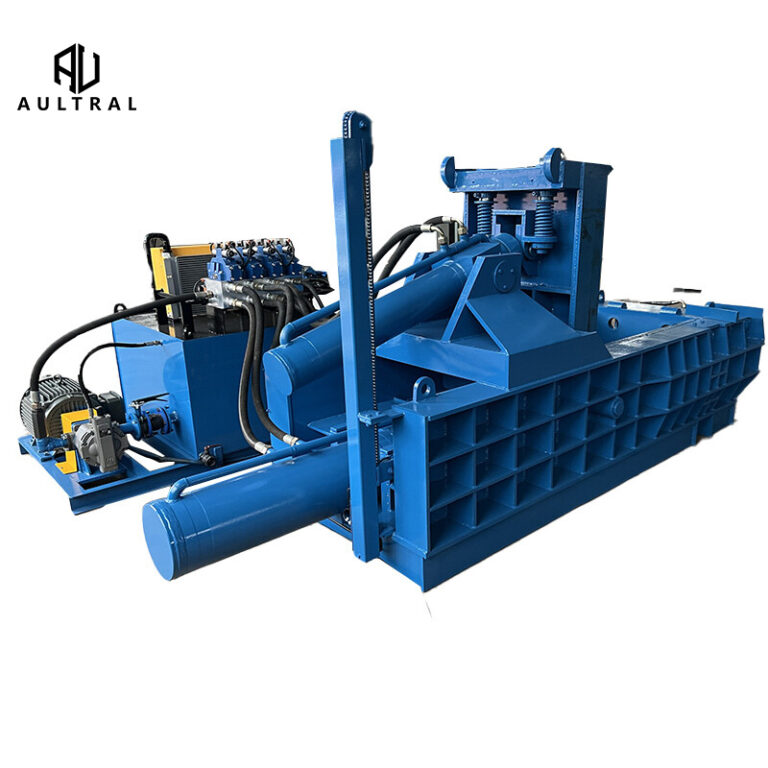

In today’s fast-paced recycling industry, the need for effective and efficient waste management solutions has never been more pressing. A Horizontal Hydraulic Metal Baler is one such solution that plays a pivotal role in the recycling of scrap metal. By compacting metal waste into dense, manageable bales, this machine helps businesses streamline their operations, reduce transportation costs, and contribute to a more sustainable future. In this article, we’ll explore the features, benefits, and reasons why investing in a horizontal hydraulic metal baler is a smart choice for your recycling business.

What is a Horizontal Hydraulic Metal Baler?

A Horizontal Hydraulic Metal Baler is a powerful machine designed to compress large volumes of scrap metal into tightly packed bales for easier storage, transportation, and further processing. The hydraulic system uses high-pressure force to compact metal waste, such as steel, aluminum, copper, and other ferrous and non-ferrous metals. These bales are then much more manageable and ready for resale or further recycling processes.

Key Features of Horizontal Hydraulic Metal Balers

-

High Compression Force

The horizontal design allows for a greater compression force, ensuring that metal waste is compacted into small, uniform bales with minimal space. This reduces storage and transportation costs by maximizing the available space, allowing businesses to handle higher volumes of material efficiently. -

Automatic Operation

Most modern horizontal hydraulic metal balers are equipped with an automatic cycle. This means that after loading the metal scrap, the baler compresses the materials, ejects the bales, and is ready for the next cycle. This reduces the need for manual labor and increases the machine’s overall productivity, making it ideal for high-volume operations. -

Versatility in Material Handling

Horizontal hydraulic metal balers are highly versatile and can handle a wide range of materials, including aluminum cans, copper wire, steel scrap, iron, and even car parts. This flexibility makes them ideal for use in various industries such as manufacturing, recycling centers, and scrap metal yards. -

Durable and Robust Design

Built with heavy-duty materials and designed to withstand continuous, high-pressure operations, horizontal hydraulic metal balers are known for their durability. They are engineered to handle the toughest scrap metal and can function effectively under demanding industrial conditions, ensuring long-lasting performance and minimal downtime. -

Energy Efficient

Many modern models of horizontal metal balers are designed with energy efficiency in mind. The hydraulic system optimizes energy usage, reducing operating costs and improving the overall sustainability of your recycling operations.

Benefits of Using a Horizontal Hydraulic Metal Baler

-

Reduced Transportation Costs

By compacting scrap metal into bales, businesses can transport more material at once. The high-density bales are easier to stack, store, and ship, which significantly reduces transportation costs. Furthermore, with less bulk to manage, businesses can reduce the number of trips needed to move metal scrap. -

Improved Space Management

Scrap metal, when left in its raw form, takes up a lot of space. With a horizontal hydraulic metal baler, you can maximize storage efficiency by converting bulky materials into compact, uniform bales. This not only saves valuable floor space but also improves overall workflow and organization within your recycling facility. -

Enhanced Safety

With fewer manual processes involved, horizontal hydraulic metal balers improve safety in the workplace. Operators are less likely to be exposed to dangerous cutting, shredding, or handling of scrap metal, reducing the risk of injuries. Moreover, the machine’s automatic operation ensures that employees are kept at a safe distance from the heavy-duty equipment during operation. -

Boosted Recycling Efficiency

The ability to handle large volumes of scrap metal with minimal human intervention makes horizontal hydraulic metal balers an invaluable tool for recycling centers. They allow businesses to process more material in less time, increasing output and boosting overall recycling efficiency.

Applications of Horizontal Hydraulic Metal Balers

-

Scrap Metal Recycling Centers

These balers are widely used in scrap metal recycling centers for compressing various types of metals like steel, aluminum, and copper. By turning loose scrap into compact bales, these centers can manage and recycle large quantities of metal more effectively. -

Manufacturing Plants

Manufacturers who produce metal waste as part of their operations benefit greatly from using horizontal hydraulic balers. They can quickly compact the metal scrap generated during production, improving their waste management system and making it easier to dispose of or recycle the materials. -

Automobile Recycling

In automobile recycling facilities, horizontal hydraulic metal balers are used to compact car parts and other metal components, ensuring they are processed in an environmentally friendly and efficient manner. -

Demolition Projects

When buildings or industrial structures are demolished, metal scrap is a common byproduct. Horizontal hydraulic balers can be used to compress this metal waste, ensuring it’s ready for recycling and repurposing.