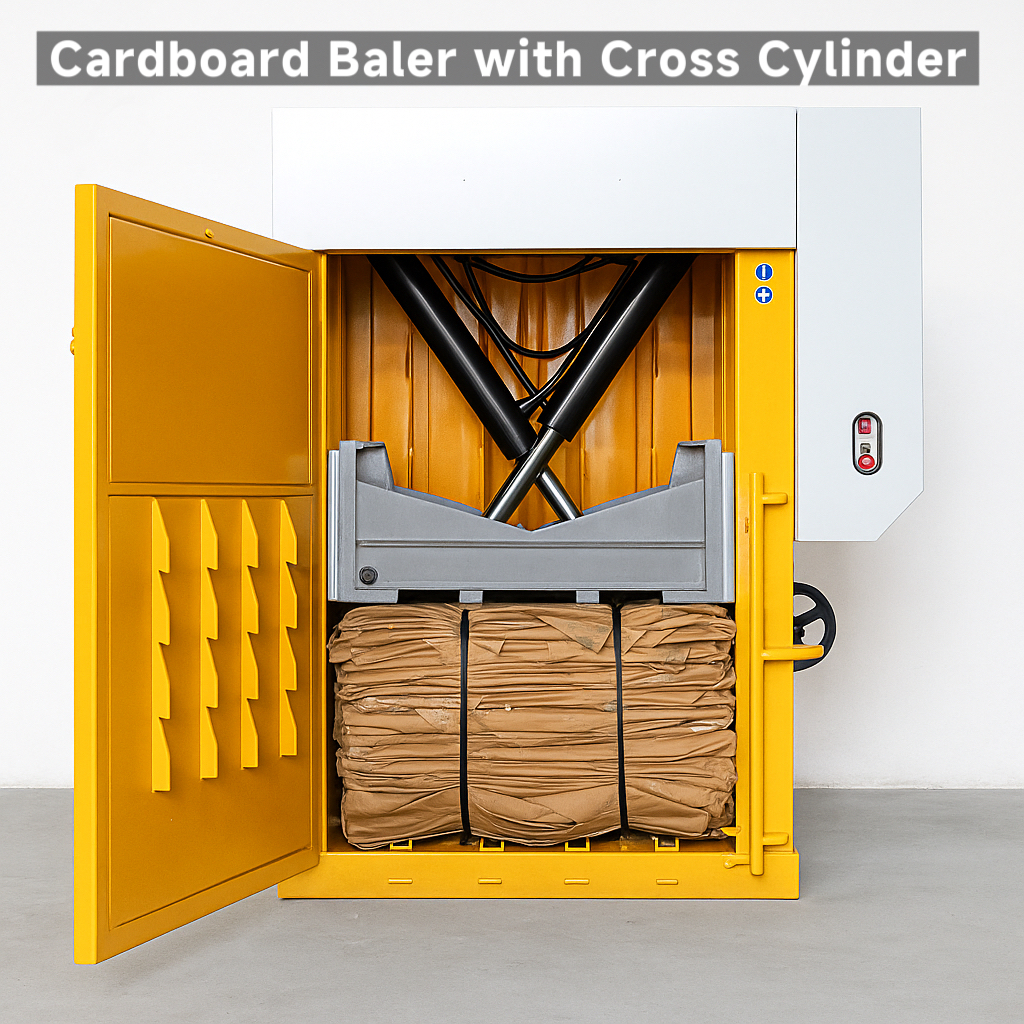

A cardboard baler with a cross cylinder is a specialized waste management machine designed to compress and bundle waste cardboard into compact bales. Compared to standard vertical or horizontal balers, this type of baler features a unique cross-cylinder structure that provides stronger pressing force, improved space efficiency, and more stable operation. For companies that deal with large amounts of cardboard waste, such as packaging plants, warehouses, supermarkets, and recycling facilities, this equipment offers an economical and practical solution.

What Is a Cardboard Baler With Cross Cylinder?

A cardboard baler with a cross cylinder is a hydraulic baling machine where the cylinder is installed horizontally across the frame instead of vertically. This design allows the machine to exert high pressure while maintaining a compact size. The cross-cylinder configuration distributes force more evenly, reduces machine height, and ensures that the baling process is smooth and consistent.

By using this machine, loose cardboard can be compressed into dense bales. These bales are easier to store, transport, and recycle, ultimately helping businesses reduce waste volume, save storage space, and cut down disposal costs.

Key Features of Cross Cylinder Design

-

Powerful Compression – The cross-cylinder layout delivers strong pressure to ensure cardboard bales are tightly packed.

-

Space-Saving Structure – Compared with vertical designs, the cross-cylinder machine requires less installation height, making it suitable for factories and warehouses with limited ceiling space.

-

Durable Frame – Heavy-duty steel construction ensures stability and long service life even under continuous operation.

-

Energy Efficiency – Equipped with a high-quality hydraulic system and motor, the machine consumes less energy while maintaining consistent performance.

-

Safety Features – Emergency stop buttons, protective covers, and automatic pressure release systems ensure safe operation for workers.

Benefits of Using a Cardboard Baler With Cross Cylinder

-

Reduced Waste Volume: Cardboard can be compressed up to 10 times smaller than its original size.

-

Lower Transportation Costs: Tightly packed bales require fewer trips, saving fuel and logistics expenses.

-

Improved Storage Management: Businesses can free up valuable floor space by reducing piles of loose cardboard.

-

Environmental Contribution: Compact bales make recycling easier, helping businesses comply with sustainability policies.

-

Operational Efficiency: Faster baling process increases productivity for waste management operations.

Applications of Cardboard Baler With Cross Cylinder

This machine is widely used across different industries:

-

Retail and Supermarkets: Compressing large volumes of carton packaging.

-

Warehousing and Logistics: Handling leftover cardboard from shipments.

-

Manufacturing Plants: Recycling cardboard packaging materials from raw material deliveries.

-

Recycling Centers: Processing waste cardboard into market-ready bales for resale.

-

E-commerce Warehouses: Managing daily cardboard waste from packaging and returns.

How to Choose the Right Model

When selecting a cardboard baler with cross cylinder, businesses should consider the following factors:

-

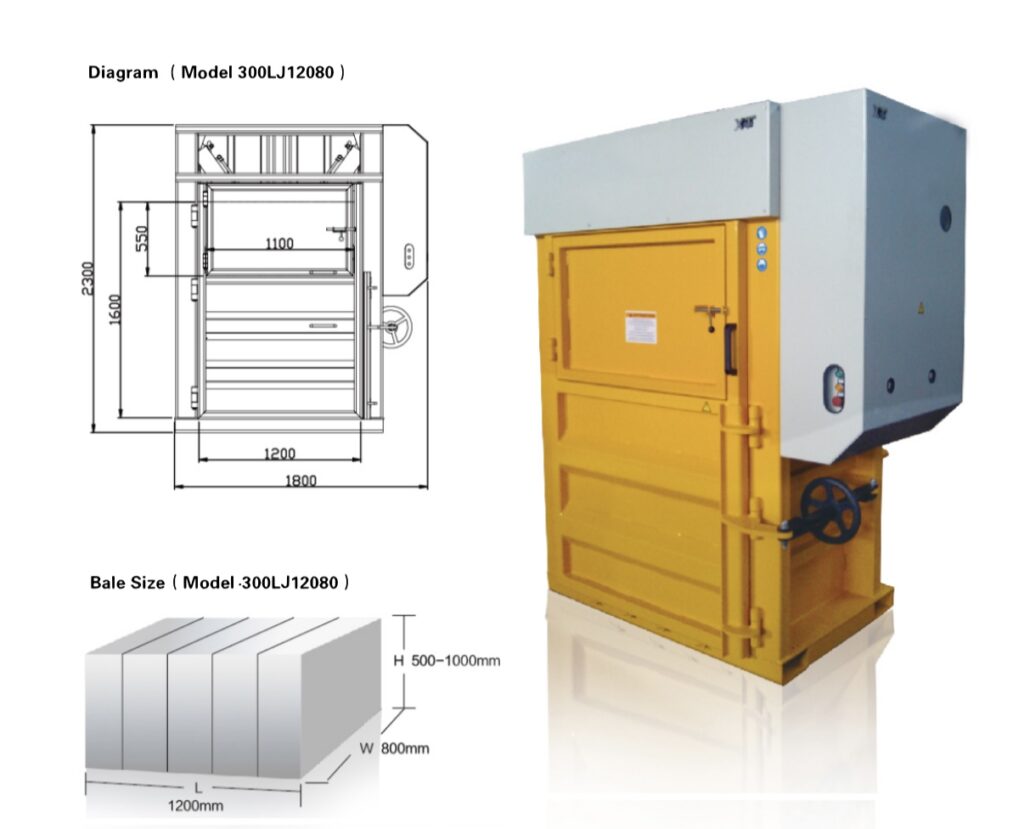

Bale Size and Weight – Choose a model that produces bales suitable for your transportation and storage requirements.

-

Processing Capacity – Consider the daily or hourly volume of cardboard waste that needs to be processed.

-

Automation Level – Options range from manual to semi-automatic and fully automatic machines.

-

Available Space – Measure the installation area, including height and width, to ensure proper machine fit.

-

Power Supply – Verify whether the baler matches the available voltage and power in your facility.

Maintenance and Safety Tips

To ensure long-lasting and safe operation of a cardboard baler with cross cylinder, regular maintenance is necessary:

-

Inspect the hydraulic system for leaks or pressure drops.

-

Check cylinder alignment and lubrication.

-

Replace worn-out blades, seals, or wires in time.

-

Train operators to follow safety guidelines strictly.

-

Schedule routine servicing with qualified technicians.

Why Invest in a Cardboard Baler With Cross Cylinder?

For businesses generating large quantities of cardboard waste, investing in this type of baler brings long-term savings and operational benefits. Not only does it reduce waste management costs, but it also improves workplace efficiency and contributes to environmental sustainability. The cross-cylinder design adds extra value by providing stronger force in a more compact structure, making it a practical choice for modern industries.

A cardboard baler with cross cylinder is an advanced and efficient solution for managing cardboard waste. With its unique structure, powerful compression, and space-saving design, it is an ideal choice for companies looking to improve recycling efficiency and reduce costs. By selecting the right model and ensuring proper maintenance, businesses can benefit from reliable performance and long-term sustainability.