As global awareness of environmental protection grows, the automotive recycling industry has become increasingly important. Every year, millions of end-of-life vehicles (ELVs) are scrapped worldwide, creating a huge demand for efficient recycling equipment. Among these, the car double shaft shredder machine plays a crucial role in breaking down and recycling waste cars safely and effectively.

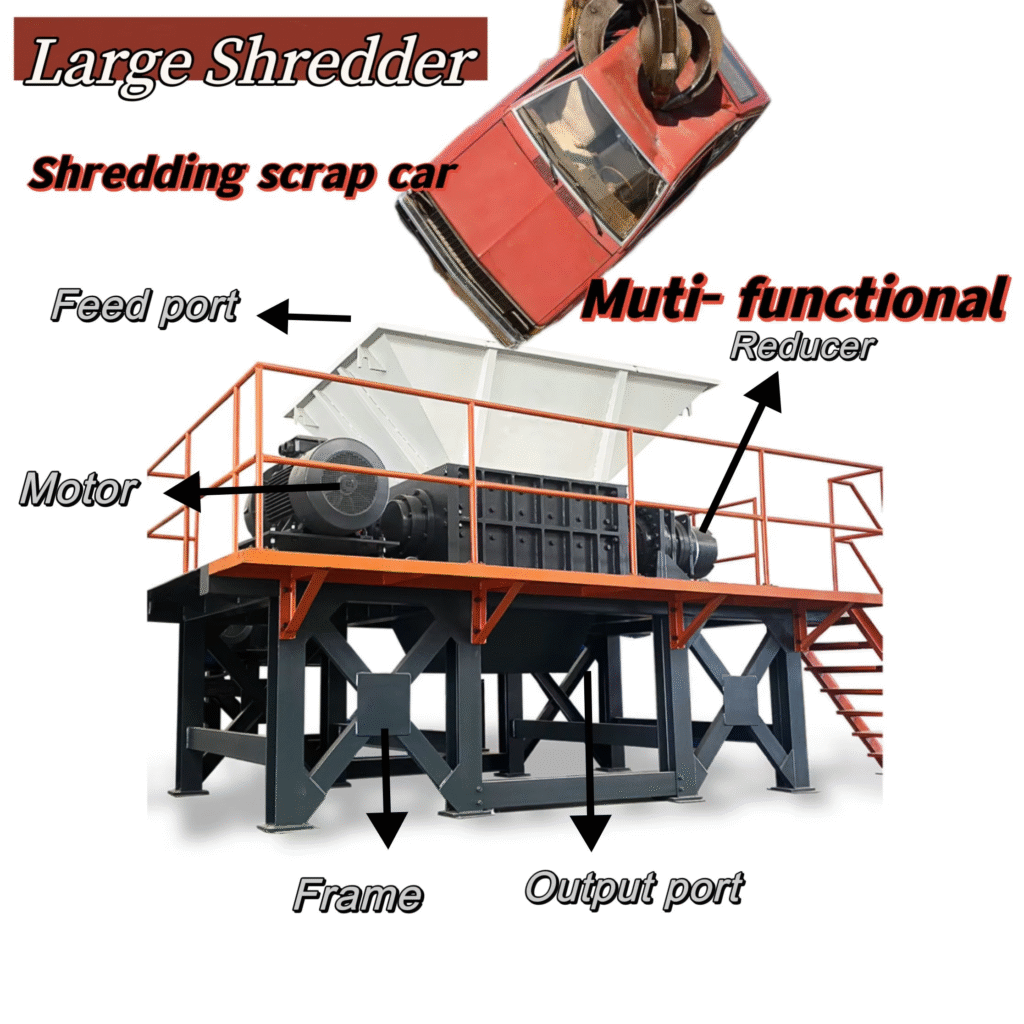

What Is a Car Double Shaft Shredder Machine?

A car double shaft shredder machine is a heavy-duty industrial shredder designed to crush and shred entire vehicles or large car parts into smaller, manageable pieces. It uses two powerful rotating shafts fitted with high-strength alloy blades to tear through metal, plastic, rubber, and even engine components.

The shredded output can then be further processed for material separation—such as steel recovery, aluminum recycling, and non-metal material sorting. This makes it an essential part of the automotive recycling chain.

How Does It Work?

The working principle of a twin shaft car shredder is simple yet powerful.

-

Feeding: The waste car or car body is placed onto the conveyor or feeding hopper.

-

Shredding: The twin shafts rotate in opposite directions. Their sharp and durable blades grip, pull, and tear the materials apart.

-

Size Reduction: The shredded fragments pass through a screen or discharge gate, producing uniform pieces suitable for further processing.

-

Discharging: The processed material is automatically discharged for sorting or transport to the next stage.

This process allows for efficient volume reduction, making storage, transport, and metal recovery much easier.

Key Features of Car Double Shaft Shredder Machine

-

High Torque, Low Speed:

The shredder operates at low speed but with high torque, ensuring maximum power and minimal noise or vibration. -

Durable Blades:

The shredding blades are made of wear-resistant alloy steel, capable of handling tough materials like engine blocks, car shells, and steel frames. -

Automatic Overload Protection:

When the shredder encounters unshreddable material, the system automatically reverses to prevent damage and resume operation smoothly. -

Heavy-Duty Structure:

The machine body is made from high-grade welded steel to withstand continuous heavy loading and long-term industrial use. -

Customizable Design:

Models can be customized according to the size, thickness, and material of the car body being processed, ensuring perfect adaptability for different recycling needs.

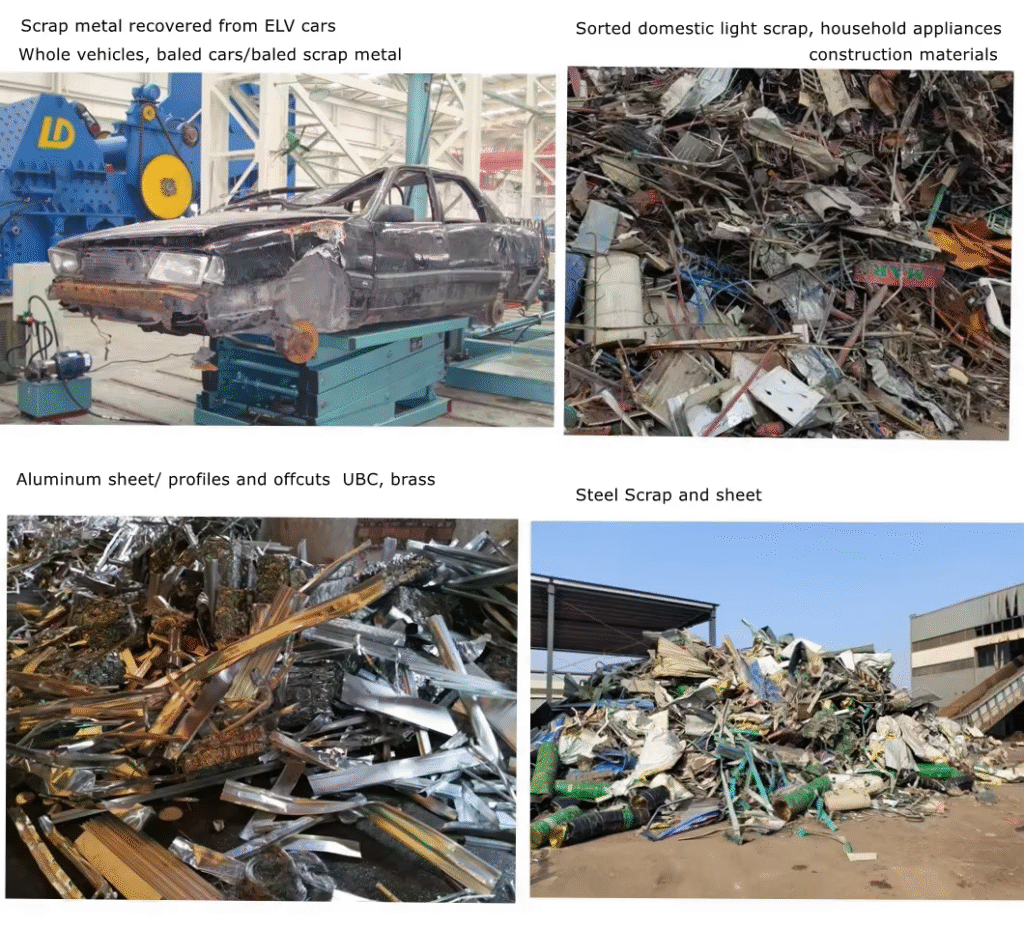

Applications in Automotive Recycling

The car double shaft shredder machine is not limited to whole vehicle shredding. It is also widely used for:

-

Car shells and frames

-

Engine blocks and transmission cases

-

Aluminum wheels and bumpers

-

Automotive plastic components

-

Electrical wiring and interiors

-

Scrap metal from car dismantling yards

By processing these materials, recyclers can recover valuable metals such as iron, copper, and aluminum, which can be melted and reused in manufacturing industries, significantly reducing the need for virgin resources.

Benefits of Using a Car Double Shaft Shredder

-

Enhanced Recycling Efficiency:

Shredding vehicles into smaller pieces makes it easier to separate materials and recover valuable components. -

Environmental Protection:

Efficient shredding helps reduce landfill waste and promotes sustainable material reuse. -

Cost Savings:

Recyclers can save on transportation and storage costs thanks to the reduced volume of shredded materials. -

Increased Safety:

Manual dismantling of vehicles can be dangerous. A shredder provides a safer, automated solution. -

Economic Value:

Recovered metals can be sold or reused, creating new revenue streams for recycling businesses.

Maintenance and Operation Tips

To ensure reliable performance and long lifespan, proper maintenance is essential:

-

Regularly inspect the blades for wear and sharpness.

-

Keep the gearbox and motor well-lubricated.

-

Check hydraulic systems and electrical components routinely.

-

Clean the discharge area to avoid material buildup.

-

Train operators to understand the control system and safety features.

A well-maintained car double shaft shredder can run continuously for years, offering stable productivity and minimal downtime.

How to Choose the Right Shredder for Your Recycling Plant

Selecting the correct model depends on your processing requirements. Here are some important factors to consider:

-

Processing Capacity: Determine how many vehicles or tons of scrap you need to handle per hour.

-

Material Type: Choose the motor power and blade material suitable for steel-heavy or mixed-material cars.

-

Output Size: Some shredders offer adjustable discharge sizes depending on your next processing step.

-

Automation Level: You can select between standard manual feeding or fully automated systems with conveyors.

-

Space and Power Supply: Ensure your factory has enough installation space and stable power sources for large-scale shredding.

Working with a trusted manufacturer allows you to get customized solutions based on your recycling goals.

Why Choose Aultral Machinery

Shanghai Aultral Machinery Co., Ltd specializes in manufacturing industrial shredders, crushers, and hydraulic balers for waste recycling industries. Our car double shaft shredder machines are CE and ISO9001 certified, known for their stable performance, strong structure, and advanced control system.

Whether you are recycling end-of-life cars, metal scraps, or mixed materials, Aultral provides reliable and energy-efficient shredding solutions tailored to your needs.