What is an Alligator Shear?

An Alligator Shear, also known as a crocodile shear, is a robust and efficient hydraulic cutting machine that plays a critical role in the recycling and scrap processing industries. The machine is named for its unique design, which features a hinged jaw that opens and closes similar to the mouth of an alligator. This powerful cutting action allows the shear to easily slice through a wide range of materials, providing an effective solution for high-demand cutting tasks.

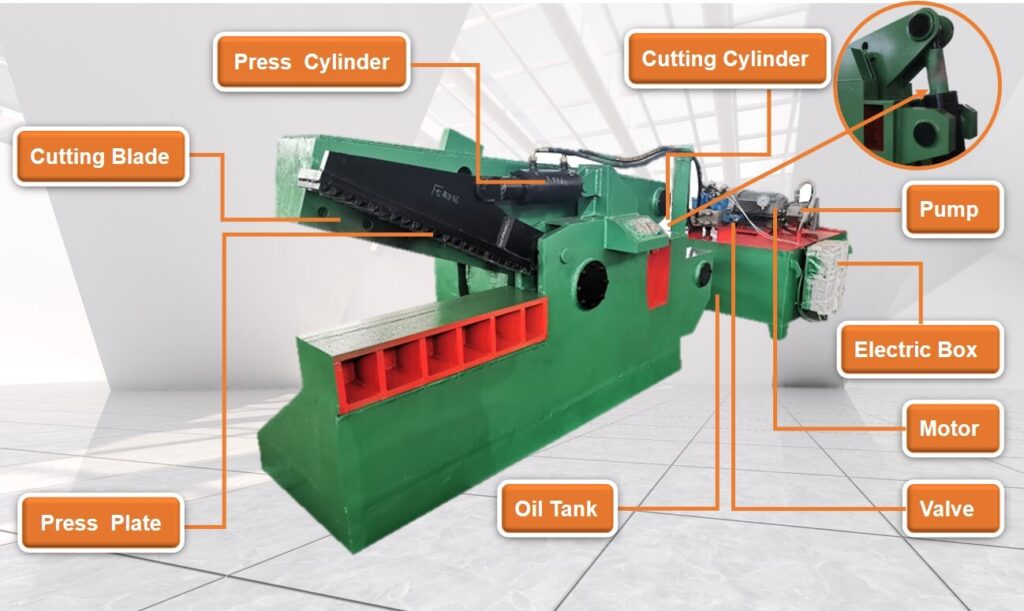

Design and Functionality

The main purpose of an alligator shear is to cut large, bulky metal scraps into smaller, more manageable pieces. These smaller sections are easier to store, transport, and process, making the recycling of metals more efficient. The shear is equipped with durable blades that are capable of cutting through heavy materials such as steel bars, pipes, I-beams, rebar, and car frames. It can also handle aluminum profiles and various non-ferrous metals, making it versatile in different scrap processing environments. By reducing the size of metal pieces, an alligator shear helps streamline subsequent processing stages, such as shredding or melting.

Advantages Over Traditional Cutting Methods

Compared to manual cutting or gas cutting, the alligator shear offers a multitude of advantages. First and foremost, its hydraulic-powered system enables faster, more efficient cuts. The shear’s high cutting capacity ensures that large amounts of metal can be processed quickly, reducing operational downtime and increasing productivity. Additionally, the machine requires less physical labor, as it can handle tough cutting tasks with minimal human effort. This leads to lower labor costs and a more ergonomically friendly working environment. Moreover, the alligator shear’s automated operation significantly improves safety, as workers are not exposed to the risks associated with manual cutting or the hazards of open flames from gas cutting.

Perfect for Scrap Yards and Metal Recyclers

Alligator shears are particularly favored by scrap yards, metal recyclers, and small to medium-sized steel processing plants. Their compact design, combined with their powerful performance, makes them a perfect fit for operations that require space-saving equipment without compromising on cutting efficiency. Whether you’re dealing with large scrap metal pieces or smaller offcuts, the alligator shear ensures that metal materials are properly sized and ready for the next phase of processing. This combination of high efficiency, ease of use, and cost-effectiveness makes the alligator shear an indispensable tool for businesses in the recycling and metal processing sectors.

Why Choose an Alligator Shear?

When it comes to scrap processing and metal recycling, efficiency, reliability, and cost-effectiveness are of paramount importance. An Alligator Shear is one of the most practical and reliable machines available for transforming large, cumbersome metal materials into smaller, more manageable pieces. This process not only enhances operational efficiency but also plays a crucial role in the smooth flow of recycling operations.

Power and Precision in Every Cut

The primary advantage of an alligator shear lies in its hydraulic-powered cutting force, which provides exceptional strength and precision when handling various materials. With its simple yet effective mechanical design, it can easily slice through tough metals such as steel bars, pipes, I-beams, and other structural components. This rapid cutting ability makes it a superior choice over manual tools or gas cutting, as it drastically reduces the time required to process materials. By reducing manual labor, the shear lowers operational costs while boosting productivity, making it a game-changer in large-scale scrap operations.

Versatility for Various Scrap Materials

An alligator shear stands out due to its remarkable versatility, able to handle a wide range of metals with ease. Whether you’re dealing with ferrous metals like rebar and car frames or non-ferrous metals such as aluminum and copper, this machine can tackle them all. Its ability to handle different types of scrap ensures that metal recyclers can maximize the value of their materials. By cutting metals down to manageable sizes, the shear prepares them perfectly for further shredding, smelting, or even direct sale, thus optimizing the recycling process.

Durability and Low Maintenance

In addition to its cutting performance, the durability and low maintenance requirements of an alligator shear are key reasons for its popularity in the industry. With fewer moving parts than other industrial cutting machines, the shear is less prone to mechanical failure. This simplicity translates into a long service life and reduced maintenance costs, even in the most demanding environments. Whether used in scrap yards or large-scale metal processing plants, an alligator shear is built to endure, offering reliable service over extended periods of heavy use.

How to Use an Alligator Shear?

Using an Alligator Shear is relatively straightforward, but following the correct steps is essential for safety and efficiency.

- Prepare the Machine

Place the shear on a flat, stable surface and connect it to the power supply or hydraulic system. Make sure all bolts and connections are secure before operation. - Check Safety Measures

Operators should always wear protective gear such as gloves, goggles, and safety shoes. Ensure that the working area is free from unnecessary objects or personnel. - Load the Material

Place the scrap metal (such as steel bars, pipes, or aluminum profiles) into the cutting jaw. The material should be positioned properly so that the blade can cut it smoothly. - Operate the Hydraulic Control

Push the control lever or press the foot pedal (depending on the model). The jaw will close like an alligator’s mouth, cutting the metal into smaller pieces. - Remove the Cut Pieces

Once the cut is complete, release the lever to open the jaw. Safely remove the processed material and prepare for the next cut. - Routine Maintenance

After use, check the blades and hydraulic oil. Regular lubrication and inspection will extend the machine’s service life.

By carefully following these steps, you can ensure that your Alligator Shear operates safely, efficiently, and with minimal downtime. Regular maintenance and proper handling will not only extend the lifespan of the machine but also ensure its optimal performance over time. Whether you are cutting through steel bars, pipes, or rebar, keeping the machine in top shape will help maximize productivity and minimize costly repairs. This makes the alligator shear a dependable and highly efficient tool for metal recycling and scrap processing, ensuring your operations run smoothly with minimal interruptions. By integrating these best practices into your workflow, you can significantly enhance the reliability and cost-effectiveness of your scrap processing operations.