In the modern scrap metal recycling industry, efficient cutting equipment plays a critical role in improving productivity, safety, and material value. Among various metal cutting machines, the hydraulic alligator shear stands out as a reliable and cost-effective solution for processing a wide range of scrap materials. Its simple structure, powerful cutting force, and easy operation make it an essential machine for recycling yards and metal processing plants worldwide.

What Is a Hydraulic Alligator Shear?

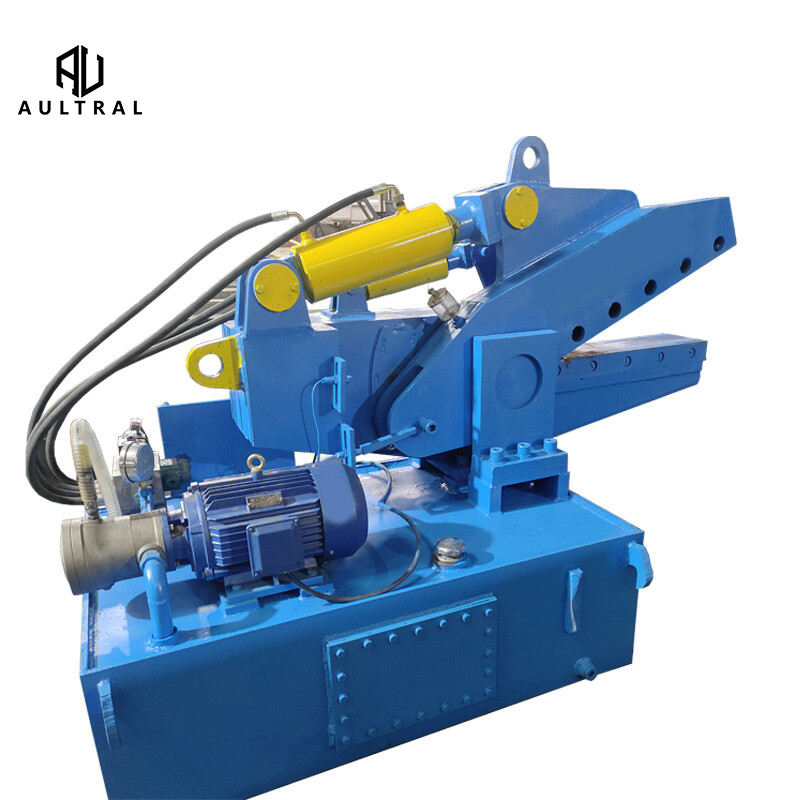

A hydraulic alligator shear is a metal cutting machine designed to shear scrap metal into shorter, manageable lengths using hydraulic power. It typically features a long cutting blade and a hinged upper jaw that resembles the mouth of an alligator—hence the name. The hydraulic system provides strong and stable cutting force, allowing the machine to handle various metal profiles with ease.

Hydraulic alligator shears are widely used to cut steel bars, rebar, pipes, angle steel, flat steel, copper rods, aluminum profiles, and light scrap metal. They are commonly found in scrap yards, metal recycling centers, steel mills, and fabrication workshops.

Key Features of a Hydraulic Alligator Shear

One of the main advantages of a hydraulic alligator shear is its practical and robust design. The machine is built with a heavy-duty steel frame to ensure stability during operation. The hydraulic cylinder delivers consistent pressure, enabling clean and efficient cutting with minimal effort.

Most hydraulic alligator shears are equipped with:

-

High-strength alloy steel blades for long service life

-

A powerful hydraulic system for smooth and stable cutting

-

Simple control options, including manual lever or foot pedal operation

-

Adjustable blade gap for different material thicknesses

These features make the hydraulic alligator shear easy to maintain and suitable for continuous industrial use.

Advantages of Using a Hydraulic Alligator Shear

High Cutting Efficiency

Compared with manual cutting methods, a hydraulic alligator shear significantly increases cutting speed and efficiency. Operators can process large volumes of scrap metal in a shorter time, improving overall productivity.

Cost-Effective Operation

A hydraulic alligator shear has a relatively simple structure and low operating costs. It consumes less energy compared to larger cutting systems and requires minimal maintenance, making it an economical choice for small to medium recycling businesses.

Improved Workplace Safety

Using a hydraulic alligator shear reduces the need for manual cutting with torches or saws, lowering the risk of workplace injuries. The controlled cutting process ensures safer and more consistent operation.

Versatile Applications

Hydraulic alligator shears can handle a wide variety of metal materials and shapes. This versatility makes them ideal for recycling mixed scrap and preparing metal for further processing, such as baling, shredding, or melting.

Applications of Hydraulic Alligator Shears

Hydraulic alligator shears are widely used across the scrap and metal recycling industry. Typical applications include:

-

Cutting long scrap metal into furnace-ready lengths

-

Processing rebar and steel rods from construction waste

-

Preparing metal for horizontal or vertical balers

-

Trimming aluminum profiles and copper bars

-

Pre-processing scrap before shredding

Their compact size and flexible installation options allow them to be used both indoors and outdoors.

How to Choose the Right Hydraulic Alligator Shear

When selecting a hydraulic alligator shear, several factors should be considered:

-

Cutting Capacity

Determine the maximum material size and thickness you need to cut. -

Blade Length

Longer blades allow for cutting larger materials in a single operation. -

Hydraulic Pressure

Higher pressure provides stronger cutting force for tougher metals. -

Operation Type

Choose between manual, foot-operated, or electrically controlled systems based on your working environment. -

Power Supply

Ensure compatibility with local voltage and electrical standards.

Choosing the right hydraulic alligator shear ensures stable performance and long-term reliability.

Maintenance and Service Life

Proper maintenance is essential to maximize the service life of a hydraulic alligator shear. Regularly checking hydraulic oil levels, inspecting hoses and seals, and sharpening or replacing blades when necessary will help maintain optimal cutting performance. With proper care, a hydraulic alligator shear can operate reliably for many years.

Why Invest in a Hydraulic Alligator Shear?

For scrap metal recyclers and metal processors, investing in a hydraulic alligator shear is a smart decision. It offers a balance of efficiency, affordability, and durability, making it suitable for businesses of all sizes. By improving cutting efficiency and reducing labor costs, the machine delivers quick returns on investment while supporting safe and sustainable recycling operations.

The hydraulic alligator shear is a proven and practical solution for scrap metal cutting and recycling. With its strong hydraulic power, simple operation, and wide application range, it remains one of the most popular metal cutting machines in the recycling industry. Whether used as a standalone unit or combined with balers and shredders, a hydraulic alligator shear helps businesses improve efficiency, reduce costs, and achieve better recycling results.