What Is a Vertical Baler?

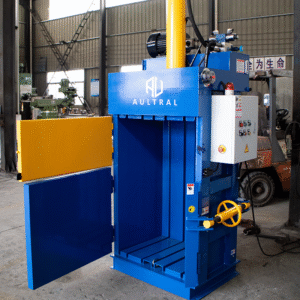

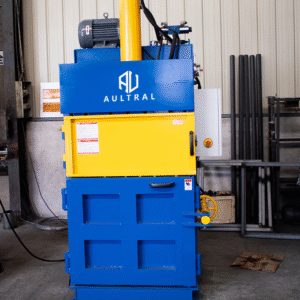

A vertical baler is a heavy-duty machine designed to compress recyclable materials such as cardboard, paper, plastics, textiles, and aluminum cans into tightly packed bales for easier handling, storage, and transportation. Unlike horizontal balers, which require more floor space and are typically used for large-scale industrial operations, vertical balers operate in an upright position, making them ideal for businesses with limited space, such as retail stores, warehouses, distribution centers, and small recycling facilities. The primary function of a vertical baler is to reduce waste volume, lowering disposal costs and improving recycling efficiency. These machines work by loading loose materials into a chamber, where a hydraulic press applies downward force to compact the waste into dense, uniform bales. Once compressed, the bales are secured with wires or straps and then ejected for storage or pickup by recycling companies.

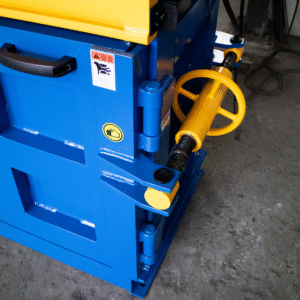

Vertical balers come in various sizes and capacities, ranging from smaller models handling a few hundred pounds of material per hour to heavy-duty industrial balers capable of processing thousands of pounds daily. Key advantages of vertical balers include their space-saving design, lower upfront cost compared to horizontal balers, and ease of operation, often requiring minimal training for employees. Additionally, they contribute to sustainability efforts by promoting recycling and reducing landfill waste. Many industries, including supermarkets, manufacturing plants, and logistics centers, rely on vertical balers to manage their waste streams efficiently. Safety features such as emergency stop buttons, safety gates, and automatic shut-off mechanisms ensure operator protection during use. Whether for cardboard recycling, plastic compaction, or metal scrap processing, a vertical baler is a cost-effective and environmentally friendly solution for businesses looking to optimize their waste management processes while supporting greener practices.

Why Use a Vertical Baler?

A vertical baler is an essential machine for businesses looking to optimize waste handling, reduce costs, and improve recycling efforts. Unlike horizontal balers, which require significant floor space and higher investment, vertical balers offer a compact, cost-effective solution for compressing recyclable materials such as cardboard, plastic, paper, and metal. One of the biggest advantages of using a vertical baler is its space-saving design, making it ideal for facilities with limited room, including retail stores, warehouses, and small recycling centers. By compacting waste into dense, manageable bales, these machines drastically reduce storage space and transportation costs, as more material can be shipped in fewer trips. Additionally, vertical balers help businesses cut waste disposal expenses since many recycling companies pay for baled materials, turning waste into potential revenue.

Another key benefit is operational efficiency—vertical balers are easy to use, often requiring minimal training, and can be operated by a single worker. With features like hydraulic pressing, automatic tying systems, and safety mechanisms such as emergency stops and safety gates, they ensure both productivity and workplace safety. Environmentally, vertical balers support sustainability by promoting recycling and reducing landfill waste, helping companies meet green initiatives and comply with waste management regulations. Industries such as supermarkets, manufacturing plants, and logistics hubs rely on vertical balers to streamline their waste processes while maintaining a cleaner, more organized workspace. Whether for cost savings, space optimization, or environmental responsibility, a vertical baler is a smart investment for any business looking to enhance its waste management strategy.

How to Use a Vertical Baler?

Operating a vertical baler properly ensures safety, maximizes efficiency, and extends the machine’s lifespan. Before starting, always wear protective gear like gloves and safety glasses, and ensure the baler is placed on a stable, level surface with adequate clearance. Begin by powering on the machine and checking that all safety features, including emergency stop buttons and safety gates, are functional. Load the recyclable materials—such as cardboard, plastic, or paper—evenly into the baling chamber, avoiding overfilling beyond the manufacturer’s recommended capacity to prevent jams or uneven compression. Once loaded, activate the hydraulic press, either manually via a control panel or automatically, depending on the model. The press will compact the materials downward with significant force, so never place hands or tools inside the chamber during this process.

After full compression, some balers automatically tie the bale with wires or straps, while others require manual securing. Ensure the bale is tightly bound to maintain its shape during handling and transport. Once secured, open the discharge door or use the ejection mechanism to remove the finished bale, taking care to lift properly or use equipment like a pallet jack for heavier bales. Clear any residual debris from the chamber before starting the next cycle to prevent malfunctions. Regular maintenance, such as inspecting hydraulic fluid levels, checking for worn components, and cleaning sensors, will keep the baler running smoothly. Always follow the manufacturer’s guidelines for specific models and prioritize training for all operators to minimize risks. By adhering to these steps, businesses can achieve consistent, safe, and efficient baling operations, reducing waste volume and boosting recycling productivity.