In the scrap recycling and metal processing industry, efficiency and cost-effectiveness are key to profitability. One of the most widely used machines to achieve this is the hydraulic horizontal metal baler. Known for its high compaction force, continuous feeding design, and robust performance, this machine is an essential solution for compressing bulky scrap into dense, manageable bales that are easy to transport, store, and smelt.

What is a Hydraulic Horizontal Metal Baler?

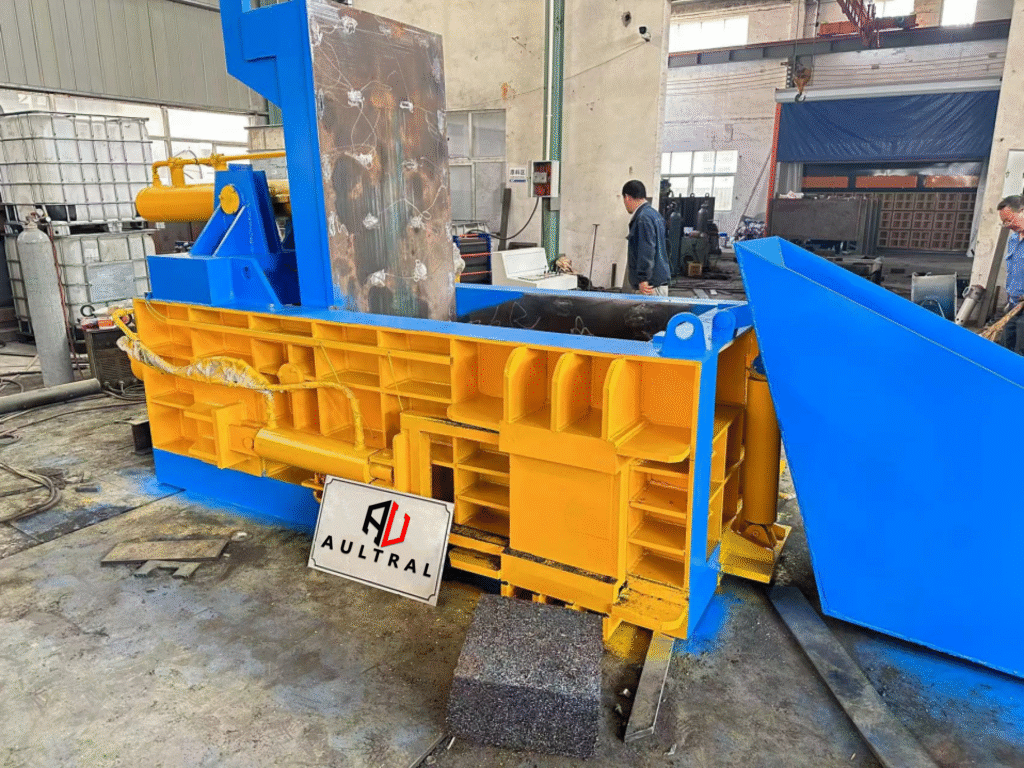

A hydraulic horizontal metal baler is a heavy-duty compaction machine that uses a horizontal hydraulic cylinder to compress loose and bulky scrap into high-density bales. Compared to vertical balers, the horizontal structure allows continuous feeding through conveyors or grab cranes, making it ideal for large-volume scrap yards and recycling plants.

Key Features of Hydraulic Horizontal Metal Balers

-

Powerful Hydraulic System – Provides strong compaction force to handle steel, aluminum, copper, and mixed scrap.

-

Wear-Resistant Structure – Heavy-duty alloy steel chamber and pressing platen designed for long service life.

-

Automatic Operation – Optional PLC control system with touch screen interface for fully automatic feeding, baling, and ejecting.

-

Continuous Feeding – Conveyor or grab crane feeding ensures uninterrupted operation and high throughput.

-

Multiple Bale Ejection Modes – Hydraulic turnover, forward push, or side push options for different plant layouts.

-

Safety Design – Equipped with emergency stop, interlock systems, and protective covers to ensure operator safety.

Applications of Horizontal Metal Balers

-

Scrap Yards: Compressing light scrap steel, profiles, and car body shells into dense bales.

-

Metal Recycling Plants: Processing aluminum cans, copper wires, and mixed non-ferrous metals.

-

Steel Mills: Preparing furnace-charge bales for efficient smelting.

-

Manufacturing Plants: Recycling stamping offcuts, sheet trims, and machining chips.

-

Demolition & Construction Waste Recycling: Compacting beams, rebars, and structural scrap.

Advantages of Using a Hydraulic Horizontal Metal Baler

-

High Efficiency: Continuous operation with conveyor feeding ensures maximum output.

-

Cost Reduction: Reduces transportation and storage costs by increasing scrap density.

-

Safety Improvement: Eliminates manual handling and reduces accident risks.

-

Space Saving: Compact scrap management even in high-volume environments.

-

Durability: Built for heavy-duty operation with minimal maintenance requirements.

Technical Parameters of Horizontal Metal Balers

Below is a typical parameter table for hydraulic horizontal metal balers (values may vary based on model and customization).

| Model | Pressing Force (Tons) | Bale Size (mm) | Chamber Size (mm) | Motor Power (kW) | Bale Weight (kg) | Capacity (T/h) |

|---|---|---|---|---|---|---|

| Y81-250 | 250 | 300×300 | 1000×600 | 30 | 80–120 | 2–4 |

| Y81-400 | 400 | 400×400 | 1400×800 | 45 | 150–250 | 4–6 |

| Y81-630 | 630 | 500×500 | 1800×1000 | 75 | 300–500 | 6–10 |

| Y81-1000 | 1000 | 600×600 | 2000×1200 | 110 | 600–900 | 10–15 |

| Y81-1250 | 1250 | 700×700 | 2200×1400 | 160 | 800–1200 | 15–20 |

How to Choose the Right Horizontal Metal Baler

When selecting a baler, consider:

-

Material Type: Light scrap, heavy scrap, or non-ferrous.

-

Production Volume: Small plants may choose 250–400T models, while large yards require 1000T+ machines.

-

Bale Size Requirement: Match bale size to furnace specifications or transportation needs.

-

Automation Needs: Decide between semi-automatic or fully automatic operation.

-

Space & Layout: Choose ejection mode (forward push, side push, or turnover) based on plant space.

Conclusion

The hydraulic horizontal metal baler is a cornerstone machine for the scrap recycling industry. With its powerful compaction force, continuous feeding design, and durable construction, it maximizes productivity while minimizing costs. Whether you operate a small scrap yard or a large-scale recycling plant, investing in the right horizontal baler will significantly improve efficiency, reduce logistics expenses, and enhance profitability.