In today’s fast-paced industrial world, efficient waste management and recycling are more important than ever. One essential piece of equipment in the metal recycling industry is the horizontal metal baler. This machine plays a critical role in compressing and baling various types of scrap metal, making transportation, storage, and recycling processes more streamlined and cost-effective.

What is a Horizontal Metal Baler?

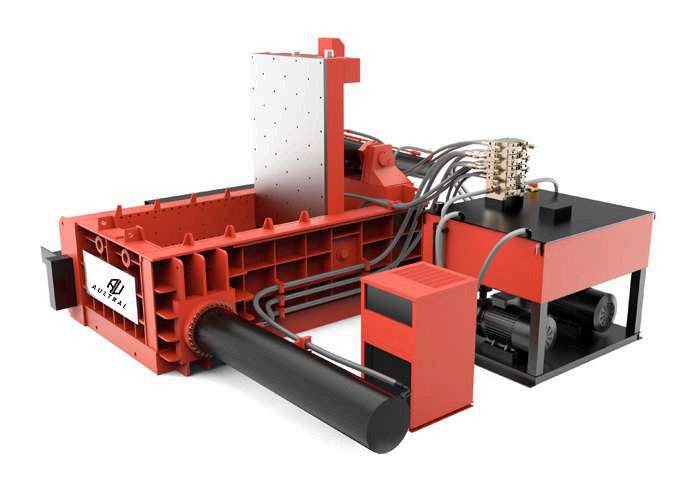

A horizontal metal baler is a hydraulic machine designed to compress metal scrap into dense, uniform bales. Unlike vertical balers, which compress materials from top to bottom, horizontal balers apply pressure horizontally, allowing for continuous feeding and higher throughput. This makes horizontal balers ideal for large-scale operations handling bulky or heavy metal scrap.

Key Features and Benefits

-

High Compression Force: Equipped with powerful hydraulic cylinders, horizontal metal balers can generate substantial pressure to compact metal scraps tightly, significantly reducing their volume.

-

Continuous Feeding System: The horizontal design allows for continuous loading of scrap metal via a conveyor or hopper, increasing operational efficiency and throughput.

-

Automated Operation: Many modern horizontal balers feature programmable controls, automatic bale tying, and safety systems, which reduce labor costs and improve workplace safety.

-

Versatility: These balers can process a wide variety of metals including steel, aluminum, copper, and iron, as well as metal chips, turnings, and other scrap forms.

-

Improved Logistics: By compressing scrap metal into dense bales, these machines reduce the space required for storage and transportation, lowering shipping costs.

Applications of Horizontal Metal Balers

-

Metal Recycling Plants: To prepare scrap metal for resale or reprocessing.

-

Manufacturing Facilities: To manage metal waste generated during production.

-

Scrap Yards: To efficiently handle large volumes of metal scrap.

-

Automotive Industry: For compressing metal parts and car scrap.

-

Construction and Demolition Sites: To process metal debris and reduce landfill waste.

Choosing the Right Horizontal Metal Baler

When selecting a horizontal metal baler, consider the following factors:

-

Bale Size and Weight: Depending on your storage and shipping requirements.

-

Compression Force: Ensure it matches the type and volume of metal you handle.

-

Automation Level: Fully automatic models can greatly increase productivity.

-

Power Requirements: Check compatibility with your facility’s electrical setup.

-

Durability and Maintenance: Robust construction and ease of maintenance are crucial for long-term operation.

Conclusion

Horizontal metal balers are indispensable in modern metal recycling and waste management industries. They help businesses save costs, improve operational efficiency, and contribute to sustainable environmental practices. Whether you run a recycling plant, manufacturing facility, or scrap yard, investing in a reliable horizontal metal baler can transform your metal handling process and boost profitability.