As global industries expand, so does the volume of scrap metal waste. From manufacturing offcuts to old appliances and vehicle parts, millions of tons of metal are discarded every year. Without proper recycling, these materials not only take up space but also pose long-term environmental risks.

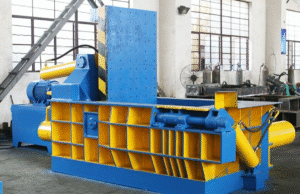

Horizontal metal balers have emerged as a vital tool in tackling this challenge — transforming loose metal scrap into compact, easy-to-transport bales. Let’s explore how these machines are shaping the recycling industry and contributing to a greener future.

🔧 What Is a Horizontal Metal Baler?

A horizontal metal baler is a heavy-duty hydraulic machine used to compress various types of scrap metal — including steel, copper, aluminum, stainless steel, and more — into dense, uniform blocks or bales.

Unlike vertical balers, horizontal balers are designed for continuous feeding, larger volume processing, and higher automation, making them ideal for industrial-scale recycling operations.

🏭 Key Applications in Metal Recycling

1. Scrap Collection & Processing

Recycling centers use horizontal metal balers to handle large quantities of loose or irregular-shaped scrap. The baler compresses the metal into stackable bales, making it easier to manage and store.

2. Steel & Foundry Industries

Metal bales produced by horizontal balers are directly fed into furnaces for remelting and reuse. This improves production efficiency and reduces reliance on virgin ore.

3. Auto & Appliance Recycling

Car bodies, engine parts, washing machines — all these metal-heavy products can be shredded and baled before being shipped to refineries for recycling.

4. Export Packaging

Many countries export scrap metal. A horizontal baler ensures that the bales are uniform in size, densely packed, and optimized for container loading, saving on international shipping costs.

🌍 Environmental Benefits

Horizontal metal balers play a vital role in supporting environmental sustainability:

-

♻️ Waste Reduction

By compressing bulky scrap metal, these machines reduce the volume of waste going to landfills. -

⚡ Energy Savings

Recycling metals consumes up to 95% less energy than extracting and refining raw ores. -

🛡️ Pollution Control

Compact, sealed bales reduce the risk of contaminants like oil, grease, and metal dust leaking into the environment. -

🌱 Supports a Circular Economy

Encouraging recycling and reuse helps preserve natural resources and reduces the carbon footprint of metal production.

✅ Advantages of Using a Horizontal Metal Baler

| Feature | Benefit |

|---|---|

| High Compression Force | Produces dense bales that save space and reduce transport costs |

| Continuous Operation | Ideal for high-volume recycling facilities |

| Customizable Bale Size | Meets various packaging and transport requirements |

| Durable Structure | Designed for long-term use under heavy-duty conditions |

| Manual or PLC Control | Flexible operation modes for different user preferences |

🔩 Our Machines in Action: A Quick Glance

Model Example: Y81F-200 Horizontal Metal Baler

-

Main Cylinder Diameter: 200mm × 2pcs

-

Side Push Cylinder: 140mm

-

Operation Mode: Manual Valve

-

Motor Power: 22kW

-

Bale Weight (Stainless Steel): 500–600kg

-

Bale Size: 250×250×(400~500)mm

-

Application: Suitable for light metal scrap, stainless steel, aluminum, copper, etc.

Whether you need to process lightweight metal scraps or bulky industrial offcuts, we offer models tailored to your capacity and layout.

📞 Let’s Work Together Toward a Cleaner Future

At Shanghai Aultral Machinery Co., Ltd., we are committed to providing efficient, durable, and environmentally friendly metal baling solutions. With years of expertise and a global customer base, we’re ready to support your recycling operations every step of the way.

📩 Interested in our horizontal metal balers?

Contact us today for a free consultation and quotation.