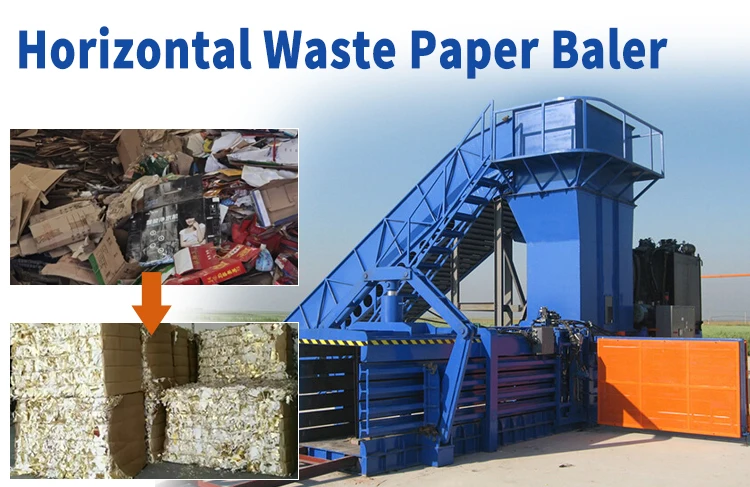

A fully automatic horizontal hydraulic baler is one of the most essential machines for modern recycling facilities, packaging plants, paper mills, and waste management companies. Designed for continuous, high-volume material processing, this machine automatically completes feeding, compressing, and bale tying, significantly improving productivity and reducing labor cost. With strong hydraulic power and intelligent automation, fully automatic horizontal balers have become the preferred equipment for handling waste paper, OCC, cardboard, plastic film, PET bottles, and other lightweight recyclables.

This article explores what a fully automatic horizontal hydraulic baler is, how it works, its advantages, key features, and how to choose the right model for your recycling needs.

What Is a Fully Automatic Horizontal Hydraulic Baler?

A fully automatic horizontal hydraulic baler is a heavy-duty baling machine that compresses loose waste materials into dense, uniform bales using hydraulic force. Unlike semi-automatic balers, this machine completes the entire baling cycle—from feeding to strapping—without manual intervention. Materials can be fed continuously through a conveyor, air cyclone, or manual feeding system, making it ideal for operations with large quantities of recyclable waste.

The machine is widely used for baling:

-

OCC (Old Corrugated Cardboard)

-

Waste paper and newspaper

-

Cardboard boxes

-

Plastic films and packaging materials

-

PET bottles

-

Textile waste

-

Foam, sponge, and other soft materials

With high efficiency and stable performance, the fully automatic baler helps companies achieve faster processing, lower transportation costs, and improved material handling.

How Does a Fully Automatic Horizontal Hydraulic Baler Work?

Although the machine is highly automated, its working process is simple and efficient:

1. Continuous Feeding

Materials are continuously delivered to the baler through conveyor belts, loaders, or air systems. There is no need for manual material handling.

2. Hydraulic Compression

A powerful hydraulic cylinder pushes the ram to compress the material inside the chamber. Multiple compression strokes ensure the bale reaches the required density.

3. Automatic Bale Length Detection

The machine uses sensors or PLC programming to detect bale length, ensuring consistent bale size.

4. Automatic Wire Tying

Once the bale reaches the preset length, the machine automatically ties the bale with steel wires or plastic straps. This process is fast, precise, and secure.

5. Bale Output

The finished bale is pushed out automatically, ready for storage or transportation.

This fully automated workflow allows the machine to operate 24/7 with minimal labor involvement.

Key Features of a Fully Automatic Horizontal Hydraulic Baler

1. Strong Hydraulic Power

The machine is equipped with heavy-duty hydraulic cylinders that generate high compression force, producing compact and stable bales.

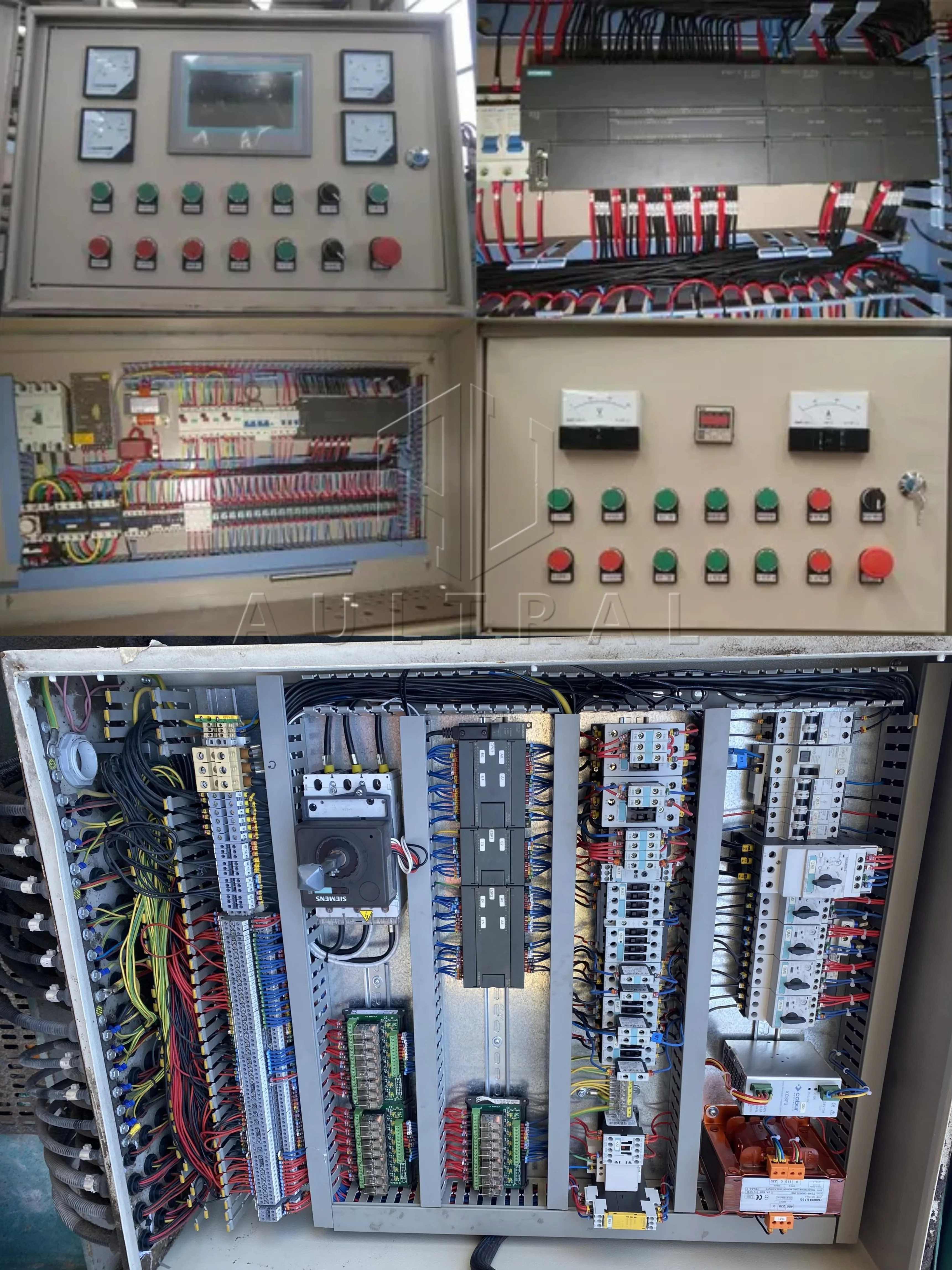

2. PLC Intelligent Control

With a smart control system, the baler offers automatic fault detection, adjustable bale length, and easy operation for all experience levels.

3. Continuous and High-Capacity Operation

Designed for large-scale recycling plants, the baler can handle tons of material per hour, making it ideal for high-volume applications.

4. Automatic Wire Tying System

The automatic tying mechanism ensures each bale is tight, uniform, and ready for transport without manual strapping.

5. Heavy-Duty Construction

The machine is built with high-strength steel plates, wear-resistant components, and robust welding to ensure long service life and low maintenance.

6. Wide Material Compatibility

From soft plastics to OCC and paper waste, this baler handles a wide range of recyclable materials.

Advantages of Using a Fully Automatic Horizontal Hydraulic Baler

1. Reduced Labor Cost

Most processes are fully automated, allowing one operator to monitor the entire system.

2. Higher Efficiency and Throughput

Continuous feeding and automatic bale tying dramatically increase production capacity.

3. Consistent Bale Quality

Uniform bale size and density improve stacking efficiency and reduce logistical costs.

4. Lower Transportation and Storage Expenses

Highly compressed bales take up less space, enabling more efficient loading for export or domestic transport.

5. Safe and Reliable Operation

Equipped with multiple safety sensors, emergency stops, and overload protection, the baler ensures stable and secure operation.

How to Choose the Right Fully Automatic Horizontal Baler

When selecting a baler, consider the following factors:

1. Material Type and Density

Different materials require different compression forces. For example, OCC and plastic films need different pressure levels.

2. Processing Capacity

Choose a model that matches your daily or hourly output requirements.

3. Feeding Method

Options include conveyor feeding, cyclone system, or manual feeding.

4. Bale Size and Weight

Consider bale dimensions required by your buyers or transportation method.

5. Automation Level and Optional Features

Optional features include:

-

automatic wire tying

-

conveyor system

-

air suction system

-

remote control

-

upgraded hydraulic power

A fully automatic horizontal hydraulic baler is an essential machine for any recycling operation that requires high efficiency, continuous production, and low labor cost. Its strong hydraulic force, advanced automation, and reliable performance make it the ideal solution for processing waste paper, cardboard, plastic films, and other recyclable materials.