In the recycling industry, efficiency, cost-effectiveness, and reliability are key factors when selecting machinery. For many recycling businesses, a used 100-ton lift door horizontal hydraulic baler is the perfect balance between performance and affordability. This article introduces what this machine is, how it works, its main advantages, applications, and detailed technical parameters to help you understand why it remains a popular choice for many waste recycling facilities.

What Is a Used 100-Ton Lift Door Horizontal Hydraulic Baler?

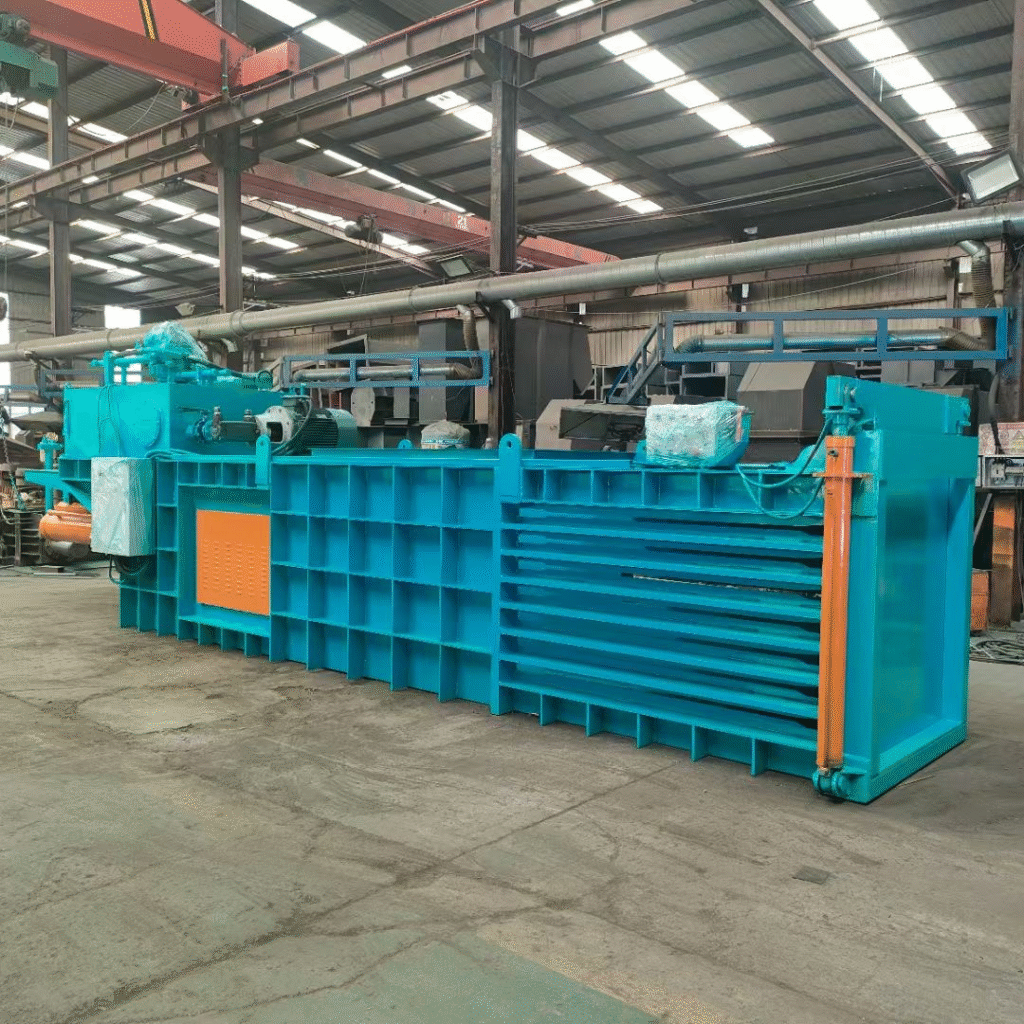

A lift door horizontal hydraulic baler is a type of waste compaction machine designed to compress various recyclable materials—such as waste paper, cardboard, plastic film, PET bottles, and textiles—into dense, easy-to-transport bales. The “lift door” design refers to its front gate that automatically rises during bale ejection, allowing for easy removal of the finished bale and reducing manual labor.

When we talk about a used 100-ton horizontal baler, we refer to a pre-owned machine with a 100-ton hydraulic pressing force that has been inspected, refurbished, and tested to ensure reliable operation. It offers almost the same functionality as a new machine but at a much lower investment cost—making it an ideal choice for startups or recycling plants looking to expand capacity on a limited budget.

Main Features of the 100-Ton Lift Door Horizontal Hydraulic Baler

The 100T lift door horizontal hydraulic baler is built to handle medium to heavy loads of recyclable materials. Its strong hydraulic system and convenient design make it both efficient and user-friendly. Here are some of its key features:

-

Powerful 100-Ton Hydraulic Force

The machine provides strong compression power to create compact, uniform bales that save storage and transportation space. -

Horizontal Structure with Lift Door Design

The lift door (front gate) rises automatically during bale ejection, simplifying the unloading process and improving workflow efficiency. -

Durable Frame and Long Service Life

The body of the baler is constructed from thick, high-quality steel plates, ensuring stability and resistance to deformation even under continuous heavy load. -

Simple Operation and Low Maintenance

The baler features a PLC control system or manual operation mode. Operators can easily control pressing, tying, and ejecting functions with minimal training. -

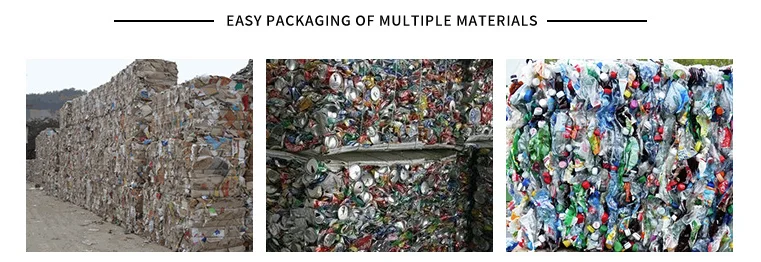

Suitable for Multiple Materials

It is capable of baling waste paper, corrugated cardboard, plastic films, bottles, fabric, and other recyclable materials. -

Affordable and Reliable

As a used machine, it provides excellent value for money while maintaining stable and efficient performance after professional inspection and reconditioning.

Technical Parameters of Used 100T Lift Door Horizontal Hydraulic Baler

| Model | Used 100T Lift Door Horizontal Hydraulic Baler |

|---|---|

| Pressing Force | 100 Tons |

| Main Cylinder | Ø180 mm |

| Bale Size (L×W×H) | 1100 × 750 × 1000 mm |

| Bale Weight | 250–400 kg (depending on material) |

| Production Capacity | 2–4 tons/hour |

| Main Motor Power | 22 kW |

| Oil Pump Pressure | 25 MPa |

| Feeding Chamber Size | 1500 × 1000 mm |

| Machine Weight | About 9 Tons |

| Power Supply | 380V/50Hz (customizable) |

| Operation Mode | Manual / PLC Control |

| Cooling System | Air Cooling or Water Cooling (optional) |

| Bale Ejection | Automatic Lift Door Ejection |

All parameters can be adjusted according to customer requirements. Before shipping, every used baler is fully inspected, tested, and repainted, ensuring it meets quality and safety standards similar to new machines.

Applications of the Used 100-Ton Horizontal Hydraulic Baler

This baler is widely used in a variety of industries and recycling facilities, including:

-

Waste Paper Recycling Plants – Compressing waste paper, cardboard, and carton boxes into dense bales.

-

Plastic Recycling Factories – Handling PET bottles, PE films, and plastic packaging waste.

-

Textile Recycling Centers – Baling waste clothes, fabric, and fibers for transportation or export.

-

Printing and Packaging Plants – Managing leftover paper and packaging scraps efficiently.

-

Waste Management Stations – Compacting mixed recyclable materials to reduce waste volume.

With its 100-ton hydraulic power, it provides stable and efficient performance across all these applications, helping users save both labor and logistics costs.

Advantages of Choosing a Used Hydraulic Baler

Purchasing a used horizontal baler offers several key benefits:

-

Lower Investment, Faster Return

You can save up to 40–60% of the cost compared to a new baler, while achieving similar compression performance. -

Tested and Refurbished

Professionally reconditioned used machines are cleaned, repaired, and tested to ensure safe and reliable operation. -

Environmentally Friendly Choice

Buying used equipment helps reduce industrial waste and supports sustainability. -

Quick Delivery

Since the machine is already available, it can be shipped immediately after final testing and inspection. -

Customizable and Upgradable

Even used balers can be modified with new motors, oil pumps, or control systems to meet specific customer needs.

Maintenance Tips for Better Performance

To keep the used 100T baler running smoothly, regular maintenance is essential:

-

Check Hydraulic Oil Levels and Cleanliness regularly.

-

Inspect Hydraulic Seals and Hoses for any signs of leakage.

-

Sharpen or Replace Cutting Blades when needed to maintain compression efficiency.

-

Lubricate Moving Parts weekly to reduce friction and wear.

-

Clean the Feeding Chamber daily to prevent material buildup.

With proper care, a used baler can operate reliably for many years.

The Used 100-Ton Lift Door Horizontal Hydraulic Baler is an excellent solution for businesses that need powerful compression capability without a high investment cost. It combines strong hydraulic force, user-friendly operation, and a durable structure suitable for various recyclable materials.