Introduction

In the recycling and scrap metal industry, efficiency and cost control are two key factors that determine business success. A used metal baler machine offers an affordable and effective solution for companies that want to improve their metal recycling process without spending too much on new equipment. However, buying a second-hand machine requires careful consideration — from machine condition to maintenance and performance.

In this article, we’ll explain why buying a used metal baler can be a smart investment, how to maintain it properly, what to check before purchasing, and how to choose the right model for your business needs.

What Is A Used Metal Baler Machine?

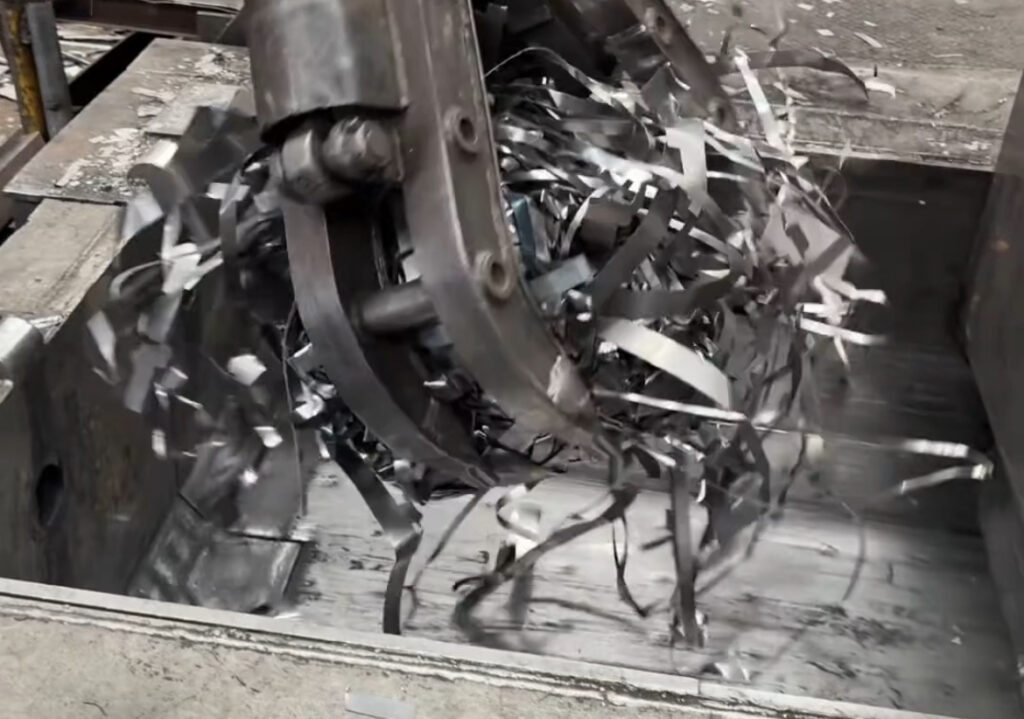

A metal baler machine is a hydraulic device designed to compress and pack various types of metal scraps — such as steel, aluminum, copper, and iron — into dense, manageable bales. These bales are easier to store, transport, and melt down for recycling.

A used metal baler simply refers to a pre-owned baling machine that has been previously operated but is still functional and reliable. These machines are often refurbished, tested, and resold at a fraction of the price of new models, making them a popular choice for small to medium-sized recycling businesses.

Why Choose A Used Metal Baler Machine

1. Cost-Effective Investment

One of the most significant advantages of buying a used baler is the lower upfront cost. A used model can cost 30–60% less than a new one, helping you save on capital expenditure while still getting the performance you need.

2. Proven Reliability

Most used machines have already been tested in real operating conditions. If the machine is from a reputable manufacturer and has been properly maintained, it can still provide many years of stable operation.

3. Shorter Delivery Time

New machines may require production and delivery time. In contrast, used machines are usually ready for immediate shipment, allowing you to start operations faster.

4. Environmentally Friendly Choice

By purchasing a used baler, you are extending the machine’s life cycle and reducing waste — an eco-friendly decision aligned with the sustainability goals of the recycling industry.

How To Maintain A Used Metal Baler Machine

Proper maintenance is essential to keep your used baler in good working condition. Here are some key maintenance tips:

1. Regular Hydraulic Oil Checks

Hydraulic systems are the heart of metal balers. Regularly check the oil level, quality, and temperature. Replace the oil and filters as recommended by the manufacturer to avoid contamination and system damage.

2. Inspect Hoses And Seals

Hydraulic hoses, joints, and seals can wear out over time. Check for any signs of leaks, cracks, or looseness, and replace worn components promptly.

3. Lubricate Moving Parts

Lubrication reduces friction and extends the lifespan of mechanical parts. Apply the proper grease to hinges, pistons, and guide rails according to your maintenance schedule.

4. Clean The Machine Regularly

Metal dust, oil residue, and debris can accumulate and affect machine performance. Regular cleaning helps prevent corrosion and ensures smooth operation.

5. Check Electrical Components

Inspect the control panel, sensors, and motor wiring to ensure all electrical systems are functioning correctly. Faulty components should be repaired or replaced immediately.

6. Perform Routine Testing

Operate the baler periodically to check for abnormal sounds, slow operation, or pressure issues. Early detection of small problems can prevent costly repairs later.

Key Points To Consider When Buying A Used Metal Baler

Purchasing a second-hand baler requires careful evaluation. Below are the most important factors to consider before making a decision:

1. Machine Condition And Working Hours

Always ask for the machine’s operating history, including total working hours, usage frequency, and previous maintenance records. A low-hour machine that has been regularly serviced is generally a safer investment.

2. Hydraulic System Performance

Inspect the hydraulic system carefully. Check for oil leaks, pressure stability, and pump noise. Weak hydraulic performance can lead to low compression force and poor bale quality.

3. Cylinder And Structure Integrity

The hydraulic cylinders and the steel frame must be in solid condition. Look for signs of wear, rust, or cracks that might affect compression strength or machine safety.

4. Electrical System And Control Panel

Ensure that all electrical components, buttons, and safety switches are working properly. Replacing outdated or damaged control systems can be costly.

5. Brand Reputation And Spare Parts Availability

Choosing a reputable brand makes it easier to find spare parts and technical support. Machines from well-known manufacturers usually have better reliability and service documentation.

6. Test Run Before Purchase

If possible, run the machine before buying. Observe the cycle speed, noise level, and pressure gauge readings. This hands-on inspection provides valuable insight into the machine’s real performance.

7. Verify Seller Credibility

Always buy from trusted suppliers or factories who can provide after-sales service, repair guidance, and warranty for key components.

How To Choose The Right Model Of Used Metal Baler

Selecting the correct model is just as important as buying a reliable used machine. Here are some practical tips:

1. Identify The Type Of Metal Scrap

Different types of metal require different compression forces.

-

Light scrap (like aluminum cans or thin steel) → 80–100 tons

-

Medium scrap (such as copper, mixed steel) → 125–160 tons

-

Heavy scrap (thick steel, car bodies) → 200–315 tons or more

2. Determine The Bale Size And Weight

Consider your transportation and storage requirements. Larger bales may save space, but smaller bales are easier to handle manually.

3. Choose Between Vertical Or Horizontal Type

-

Vertical metal balers: suitable for small volumes and manual operation.

-

Horizontal metal balers: ideal for continuous, large-scale processing.

4. Evaluate Power Source

Most metal balers operate using hydraulic power and require stable three-phase electricity. Make sure the machine voltage matches your local standard (e.g., 380V, 415V, or 220V).

5. Check Automation Level

Semi-automatic and fully automatic models can save labor and time, but they also cost more. Choose a machine that fits your production volume and budget.

Advantages Of Buying From A Professional Supplier

Working with a reliable supplier brings several benefits:

-

Detailed machine inspection report before shipment

-

Refurbishment with replaced key parts (seals, motors, blades)

-

Technical support and installation guidance

-

Warranty on hydraulic system or motor

A professional supplier ensures that the used metal baler you purchase is safe, efficient, and ready to work as soon as it arrives at your facility.

Conclusion

Buying a used metal baler machine can be a smart and cost-effective decision for many recycling and scrap processing businesses. When selected and maintained properly, a second-hand baler can perform almost as well as a new one — while saving you thousands of dollars in investment.

Before purchasing, carefully check the machine’s condition, hydraulic system, and supplier credibility. Once in operation, regular maintenance and proper usage will ensure long-term reliability and efficiency.

Whether you’re handling aluminum, steel, or copper scrap, a well-chosen used metal baler can help you maximize recycling efficiency, reduce costs, and contribute to a greener future.