Efficient waste management is no longer just a matter of convenience – it is a necessity for modern businesses. From warehouses to retail chains, from manufacturing plants to recycling facilities, companies are under increasing pressure to manage waste in a cost-effective, space-saving, and environmentally friendly way. That’s where balers come in.

Balers are machines designed to compress recyclable materials such as cardboard, plastic, paper, and metal into compact bales for easier storage, transport, and recycling. However, not all balers are the same. One of the most important decisions you’ll face when considering a baler for your business is whether to choose a vertical baler or a horizontal baler.

This article will provide a detailed comparison of vertical vs. horizontal balers, including their features, benefits, costs, and best applications. By the end, you will have a clearer picture of which baler type is the right fit for your business.

What Is a Vertical Baler?

A vertical baler, sometimes called a downstroke baler, is a machine in which recyclable material is loaded from the front, and compression is applied vertically using a downward hydraulic ram. Once compacted, the finished bale is tied manually and removed from the front of the machine.

Key Features:

- Operates with a vertical press.

- Smaller footprint compared to horizontal balers.

- Typically requires manual loading and tying.

- Bale size and weight are usually smaller (100–600 kg depending on the machine).

- Commonly used for cardboard, soft plastics, textiles, and paper.

Advantages:

- Space-saving – Ideal for small businesses with limited floor space.

- Lower cost – Affordable initial investment and lower maintenance costs.

- User-friendly – Easy to operate, even for employees with minimal training.

- Versatility – Can handle different types of recyclable materials.

Disadvantages:

- Lower throughput – Not suitable for businesses generating large volumes of waste.

- Manual operation – Requires more labor to load, tie, and remove bales.

- Smaller bale size – May result in higher transportation costs for large-scale operations.

What Is a Horizontal Baler?

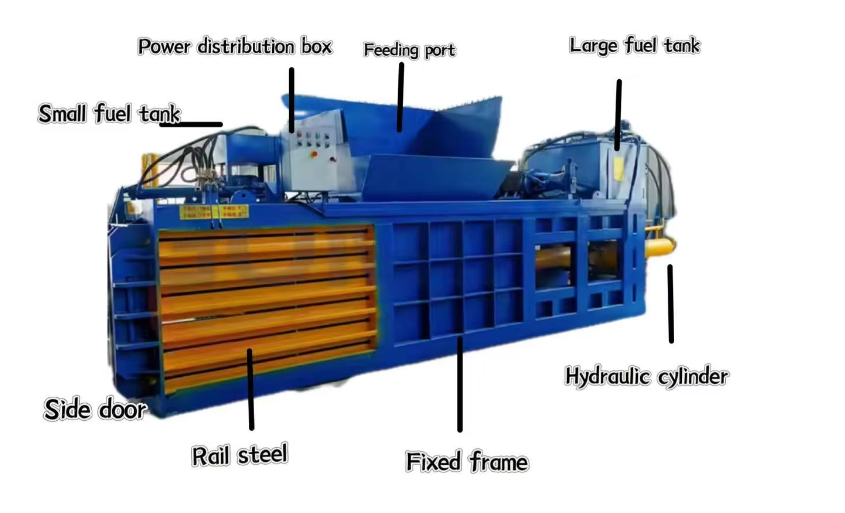

A horizontal baler compresses waste material horizontally. Materials are loaded from the top (sometimes via a conveyor belt), and a hydraulic ram pushes the material into a chamber to form a bale. Most horizontal balers are semi-automatic or fully automatic, which reduces manual labor.

Key Features:

- Operates with a horizontal press.

- Larger footprint compared to vertical balers.

- Can be integrated with conveyors for automatic feeding.

- Produces larger and denser bales (up to 1200–1500 kg).

- Well-suited for high-volume applications.

Advantages:

- High efficiency – Capable of processing large amounts of material continuously.

- Automation – Reduces labor costs with automatic feeding, compaction, and tying.

- Bigger, denser bales – Reduces transportation costs.

- Durable and long-lasting – Built for industrial use.

Disadvantages:

- Higher cost – Requires a larger initial investment.

- Space requirements – Needs more floor space for installation and operation.

- Maintenance – More complex systems mean higher servicing costs.

Vertical vs. Horizontal Balers: A Side-by-Side Comparison

| Factor | Vertical Baler | Horizontal Baler |

|---|---|---|

| Footprint | Compact, small floor space | Large, requires spacious area |

| Bale Size | 100–600 kg | 400–1500 kg |

| Cost | Low initial investment | High initial investment |

| Operation | Manual loading and tying | Semi-automatic or fully automatic |

| Throughput | Low to medium | High-volume continuous operation |

| Best For | Small to medium businesses | Large-scale industrial and recycling use |

| Maintenance | Simple, low cost | Complex, higher cost |

| Labor Demand | Higher | Lower |

Which Baler Should You Choose?

The choice between vertical and horizontal balers depends on your business’s specific needs. Here are some scenarios to help guide your decision:

Choose a Vertical Baler If:

- You run a small to medium business such as a retail store, supermarket, hotel, or office building.

- You have limited floor space but still want to manage recyclable waste efficiently.

- You generate a moderate amount of recyclable material each week.

- Your budget is limited, and you need a low-cost solution.

Choose a Horizontal Baler If:

- You operate a large-scale business such as a distribution center, recycling facility, manufacturing plant, or logistics hub.

- You handle large volumes of waste on a daily basis.

- You want to reduce labor costs with automation.

- You aim to maximize transportation efficiency by producing large, dense bales.

- You have sufficient space and budget for a long-term investment.

Cost Considerations

One of the biggest differences between vertical and horizontal balers is the cost.

- Vertical Balers: Generally range from a few thousand to tens of thousands of dollars depending on size and capacity. They also incur lower electricity costs and minimal maintenance expenses.

- Horizontal Balers: Can range from $50,000 to $500,000 or more, depending on whether they are semi-automatic or fully automatic. However, the higher cost can be offset by labor savings, improved efficiency, and reduced transport expenses.

Environmental Impact

Both vertical and horizontal balers contribute significantly to sustainability efforts by:

- Reducing landfill waste.

- Promoting recycling and circular economy practices.

- Lowering carbon emissions from transportation (by producing compact bales).

For businesses aiming to improve their green credentials, either baler type is a valuable tool. The choice depends more on scale than on sustainability impact.

Real-World Examples

- Retail Chain with Limited Space: A large retail store producing moderate cardboard waste installed a vertical baler. The machine saved warehouse space and reduced waste disposal costs by 30%.

- Recycling Facility: A regional recycling center switched from multiple vertical balers to one horizontal baler with conveyor feeding. The change cut labor costs by 40% and tripled bale output per day.

Conclusion

When it comes to vertical vs. horizontal balers, there is no one-size-fits-all solution. The right choice depends on your waste volume, available space, budget, and long-term goals.

- If you are a small or medium business with limited space and moderate waste, a vertical baler is the perfect solution.

- If you run a large-scale operation with high waste output and want maximum efficiency, a horizontal baler will deliver better results.

Investing in the right baler not only saves money and space but also enhances your company’s environmental responsibility and overall operational efficiency.

Need expert advice? At Aultral, we specialize in both vertical and horizontal balers designed for different business needs. Contact us today to find the perfect baler that matches your operation and start turning waste into value.