In today’s fast-paced industrial landscape, waste management is no longer just about compliance—it’s about efficiency, cost reduction, and environmental responsibility. Whether you’re operating a recycling facility, a distribution center, or a manufacturing plant, managing waste smartly can significantly impact your bottom line.

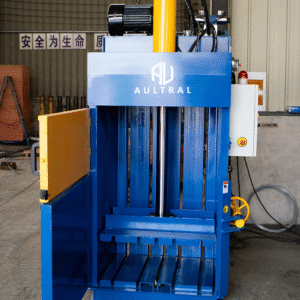

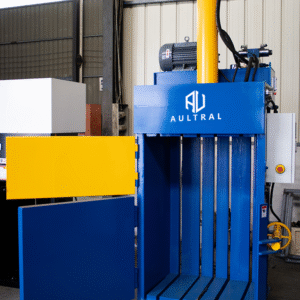

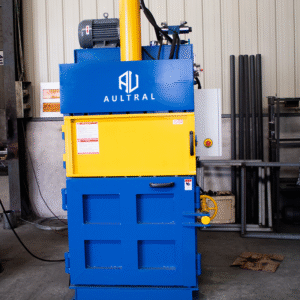

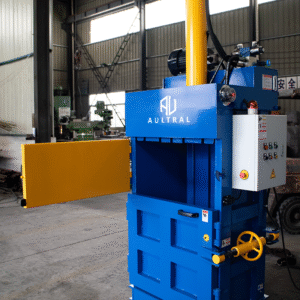

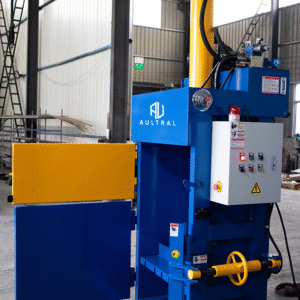

Among the many machines available in the market, vertical high-end balers stand out as a reliable, space-saving, and cost-efficient solution. These advanced machines are designed not only to compress waste materials into compact bales but also to meet the increasing demands for automation, durability, and operational safety.

This article dives into the features, benefits, and applications of vertical high-end balers, making it clear why they are a top choice for modern businesses.

What Is a Vertical High-End Baler?

A vertical baler, also known as a stand-up or upright baler, is a machine used to compress recyclable materials into dense, manageable bales. Unlike horizontal balers, vertical balers use a top-down compaction method. High-end vertical balers take this basic function to the next level by incorporating features like:

-

Heavy-duty hydraulic systems

-

Automated operation

-

Touchscreen PLC controls

-

Enhanced safety mechanisms

-

Robust structural design for long-term performance

They are especially ideal for facilities that handle moderate to high volumes of materials but have limited space.

Core Features of a Vertical High-End Baler

What makes a baler “high-end”? It’s the blend of performance, safety, intelligence, and adaptability. Here are the key components and features you can expect in a vertical high-end baler:

1. Powerful Hydraulic System

Equipped with high-pressure hydraulic cylinders, these balers exert immense force to compress materials such as cardboard, plastic, textiles, aluminum cans, and even light metal scrap. Some models can reach a pressure of up to 100 tons.

2. PLC Control with HMI Interface

Modern vertical balers come with an easy-to-use programmable logic controller (PLC) and a touchscreen interface, enabling operators to manage settings, monitor performance, and troubleshoot problems in real time.

3. Sturdy Construction

High-end balers are built with reinforced steel frames and industrial-grade welding. The machine is engineered to endure continuous, heavy-duty usage with minimal maintenance.

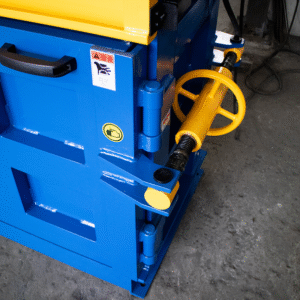

4. Safety First

Safety interlocks, emergency stop buttons, safety doors, and automatic shut-offs are standard in these machines. Operators are protected at every stage of the process.

5. Space Efficiency

Vertical balers have a smaller footprint compared to horizontal models, making them perfect for businesses with space constraints but high baling needs.

6. Customizable Bale Sizes

Many high-end vertical balers allow for adjustable bale sizes and weights to suit different logistics and recycling requirements.

Advantages of Using Vertical High-End Balers

💡 1. Save Storage Space

By compacting waste materials into dense bales, you can free up valuable warehouse or shop floor space that would otherwise be cluttered with loose material.

💰 2. Lower Disposal Costs

Compact bales reduce the frequency of waste pickups and maximize container loads, saving on transport and landfill fees.

🌍 3. Improve Recycling Rates

Sorted and baled materials are more attractive to recyclers. With a baler, you can segregate different types of waste and create value from what was previously just garbage.

🔧 4. Easy to Maintain

Despite their power, high-end vertical balers are designed with user-friendly maintenance systems. Some even come with remote diagnostic options.

👨🏭 5. Simplified Operation

Automated features such as auto-eject, bale full indicator, and programmable compression cycles make it easy for even non-technical staff to operate the machine safely and effectively.

Applications: Where Are Vertical High-End Balers Used?

Vertical high-end balers are versatile and used in a wide range of industries, including:

🏢 Retail & Supermarkets

Retail stores generate huge amounts of cardboard packaging and plastic wrap. A baler helps compact this waste, keeps the back-of-house organized, and reduces fire hazards.

🏭 Manufacturing & Industrial Facilities

Factories that produce off-cuts, textiles, foam, or scrap metal benefit greatly from on-site waste compression to keep production lines clean and efficient.

🚚 Distribution Centers & Warehouses

With daily shipments and returns, these facilities produce a significant amount of packaging waste that needs to be managed quickly and cleanly.

🧼 Hospitals & Hotels

These institutions use balers for linen, plastic bottles, and paper waste, contributing to better hygiene and a greener image.

🗑️ Recycling Companies

Recyclers use vertical balers to compact sorted materials before resale, improving transport and maximizing profits.

Choosing the Right Vertical High-End Baler

When selecting a vertical baler, you should consider:

-

Material type: Are you compressing plastic, paper, textile, or aluminum?

-

Volume of waste: Daily throughput determines pressing force and chamber size.

-

Bale size and weight: Depending on how you store and transport the bales.

-

Operation level: Manual, semi-automatic, or fully automatic.

-

Safety requirements: Especially for facilities with many employees or public access.

It’s also important to choose a supplier who offers installation, training, and after-sales support.

Why Choose Our Vertical High-End Baler?

Our vertical high-end balers are engineered to deliver superior performance with minimal downtime. Here’s what sets us apart:

✅ CE-certified for international safety standards

✅ Heavy-duty models ranging from 30 to 100 tons pressure

✅ Fully automatic options with bale eject system

✅ Reinforced steel structure for 10+ years of service life

✅ OEM customization available for chamber size, voltage, and logo

✅ Global export experience, with machines in 30+ countries

✅ Affordable EXW/FOB pricing and fast delivery from stock

Final Thoughts

If you’re in the market for a space-saving yet powerful waste compaction machine, vertical high-end balers are a smart investment. They’re efficient, environmentally friendly, and built to handle modern waste management needs.

Whether you’re running a busy logistics warehouse, a retail chain, or a recycling facility, upgrading to a high-end vertical baler can streamline your operations, cut costs, and enhance your environmental responsibility.

Ready to take your waste handling to the next level?

Contact us now for specifications, pricing, and a video demo of our top-selling vertical high-end balers.

Let me know if you’d like to convert this into a product page, brochure, or add specific models and pricing.