In today’s competitive recycling industry, choosing the right equipment can make all the difference in efficiency, cost, and profitability. A Used Metal Baler Machine provides an ideal balance between performance and price, helping businesses compress metal waste efficiently without the high upfront cost of new machinery. Whether you handle steel, aluminum, copper, or iron scraps, this machine transforms bulky materials into compact, easy-to-transport bales that maximize storage space and reduce logistics costs.

Why Choose A Used Metal Baler Machine

When it comes to recycling operations, many companies prioritize reliability, affordability, and practicality. That’s exactly what a used metal baler delivers.

-

Cost-Effective Investment

Buying a used metal baler allows you to save significantly compared to purchasing a new one. These machines often cost 40–70% less while offering comparable performance, making them ideal for small and medium recycling plants or new businesses looking to minimize capital expenses. -

Proven Performance And Reliability

Each pre-owned baler is carefully inspected, refurbished, and tested to ensure stable hydraulic pressure, consistent operation, and safe performance. It delivers the same durability and compression force as a new unit, ensuring long-term use with minimal risk. -

Environmentally Friendly Choice

Choosing a used baler supports environmental sustainability by extending the life cycle of industrial machinery and promoting resource reuse. It’s a green investment that benefits both your business and the planet. -

Wide Application Range

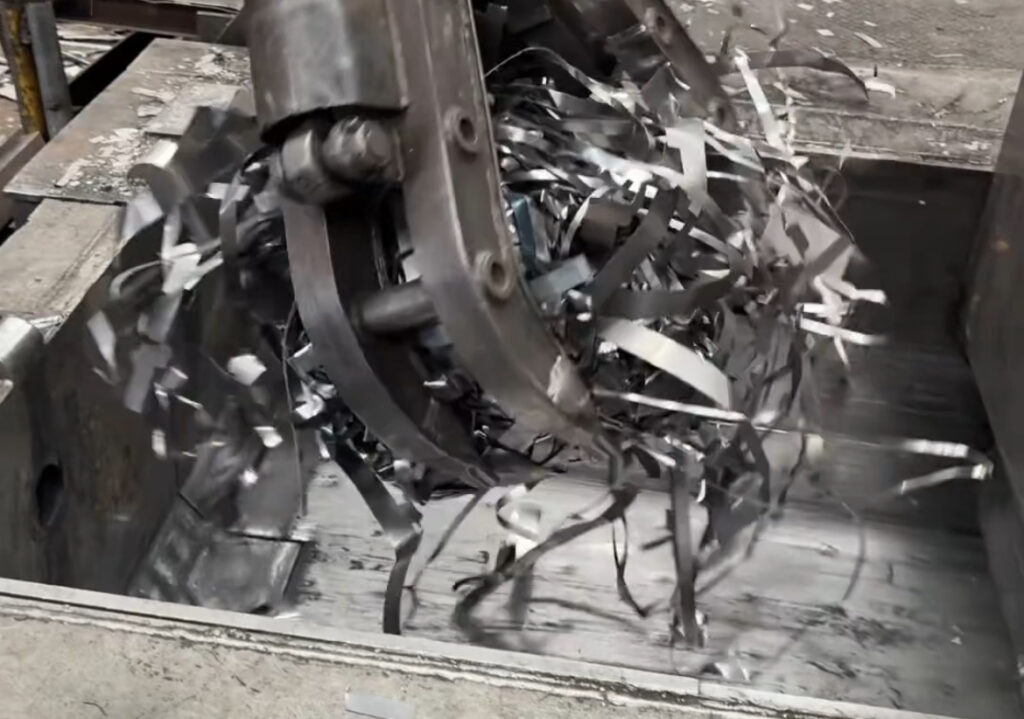

Used metal balers are suitable for a variety of recyclable materials, including scrap steel, aluminum profiles, copper wires, stainless steel sheets, and iron shavings. They can also be used in automotive dismantling plants, metal recycling centers, and foundries.

Practical Features That Improve Your Workflow

-

High Compression Ratio

A robust hydraulic system provides strong compression force to produce dense, uniform bales, reducing the volume of metal waste by up to 80%. -

Simple And Safe Operation

Most used metal balers feature intuitive controls and built-in safety systems, making them easy to operate even for non-technical workers. -

Durable Structure

Heavy-duty welded steel frames ensure long service life and withstand continuous, heavy workloads. -

Flexible Discharge Methods

Depending on the model, bales can be ejected through a side push, front push, or flip type design — allowing for smooth and efficient handling. -

Low Maintenance Requirements

The straightforward structure and readily available spare parts make it simple to maintain and repair, minimizing downtime and service costs.

Economic Benefits That Boost Your Business

A Used Metal Baler Machine is not only a piece of equipment but a tool that directly increases your profit margins.

-

Lower Initial Cost: Pay less and get faster returns on investment.

-

Reduced Operating Expenses: Efficient compression saves on storage, labor, and transportation.

-

Reliable Performance: Refurbished machines are re-tested for hydraulic stability and mechanical accuracy.

-

Quick ROI: Most users recover their investment within a few months due to high scrap value and operational savings.

-

Sustainable Operation: Supports long-term business growth while maintaining eco-friendly standards.

User Guide: How To Operate A Used Metal Baler Safely And Efficiently

Proper operation ensures longer life, better performance, and safer use of your baler.

-

Before Starting

-

Inspect the hydraulic oil level, hoses, seals, and electrical system.

-

Make sure all safety devices and emergency stops are functional.

-

Check that the power supply matches the machine’s rated voltage.

-

-

Feeding Materials

-

Load scrap metals evenly into the chamber. Avoid overfilling.

-

Separate non-metal materials to prevent equipment damage.

-

-

Operating The Hydraulic System

-

Close the chamber door securely before compression.

-

Set the pressure based on metal type — higher for steel, lower for aluminum or copper.

-

Monitor the pressure gauge and stop if unusual vibration or sound occurs.

-

-

Bale Ejection And Handling

-

Use the designated ejection mode (side push, front push, or turn-out).

-

Stack bales on a flat surface to prevent rolling or collapse.

-

-

After Operation

-

Turn off the power and release system pressure.

-

Clean metal residues inside the chamber.

-

Inspect for oil leaks and loose fittings regularly.

-

-

Maintenance Tips

-

Change hydraulic oil every 6–12 months depending on workload.

-

Lubricate moving parts weekly.

-

Replace worn seals and hoses promptly to prevent hydraulic failure.

-

Model Selection Guide: How To Choose The Right Used Metal Baler

Selecting the right model is essential to achieving optimal performance and efficiency. Here’s what to consider:

-

Type Of Scrap Material

-

For light metal such as aluminum or thin steel, choose a baler with medium pressure (60–100 tons).

-

For heavy steel or industrial scrap, opt for high-pressure models (150–300 tons) to ensure proper compression.

-

-

Bale Size And Weight

-

Determine your desired bale dimensions and density. Compact bales save space but require higher pressure.

-

-

Production Capacity

-

Estimate your daily or hourly output. If processing over 3 tons/hour, a larger chamber and motor (≥22kW) is recommended.

-

-

Operation Mode

-

Manual Type: Best for small operations with low output.

-

Semi-Automatic: Balances cost and efficiency; suitable for medium-sized recycling businesses.

-

Fully Automatic: Ideal for large plants that require continuous, high-volume production.

-

-

Installation Space And Power Source

-

Check available floor space and ensure compatibility with your factory’s power supply (380V/415V/480V).

-

-

Supplier Reliability

-

Buy from trusted sources that provide maintenance support, spare parts, and detailed refurbishment reports.

-

Tips For Buying A Quality Used Metal Baler

-

Request inspection photos or videos before purchase.

-

Ask for a performance test under load to confirm hydraulic pressure stability.

-

Ensure the oil cylinders, valves, and pumps have been checked or replaced.

-

Verify that safety systems and control panels are fully functional.

-

Prefer machines from well-known brands with available spare parts.

Environmental And Social Impact

Investing in a Used Metal Baler Machine not only saves money but also contributes to environmental protection. It reduces landfill waste, lowers carbon emissions from raw metal production, and supports the circular economy by promoting metal reuse and recycling. Every bale produced is a step toward a cleaner and more sustainable future.

Conclusion: A Smart Investment For Long-Term Growth

A Used Metal Baler Machine combines practicality, affordability, and durability in one reliable package. It’s the ideal choice for recycling centers, metal dealers, and manufacturing plants that value efficiency and cost savings. With proper operation, regular maintenance, and smart model selection, a used baler can deliver outstanding performance for many years.

Start your recycling journey today with a quality Used Metal Baler Machine — the smart, sustainable, and profitable choice for modern metal processing.