In an age of increasing environmental consciousness and stricter recycling regulations, vertical balers have emerged as indispensable tools for businesses across various industries. These machines, known for their compact design and powerful compression capabilities, help organizations manage waste more efficiently while cutting operational costs. This article explores the wide-ranging applications of vertical balers and discusses effective strategies to promote their adoption in different markets.

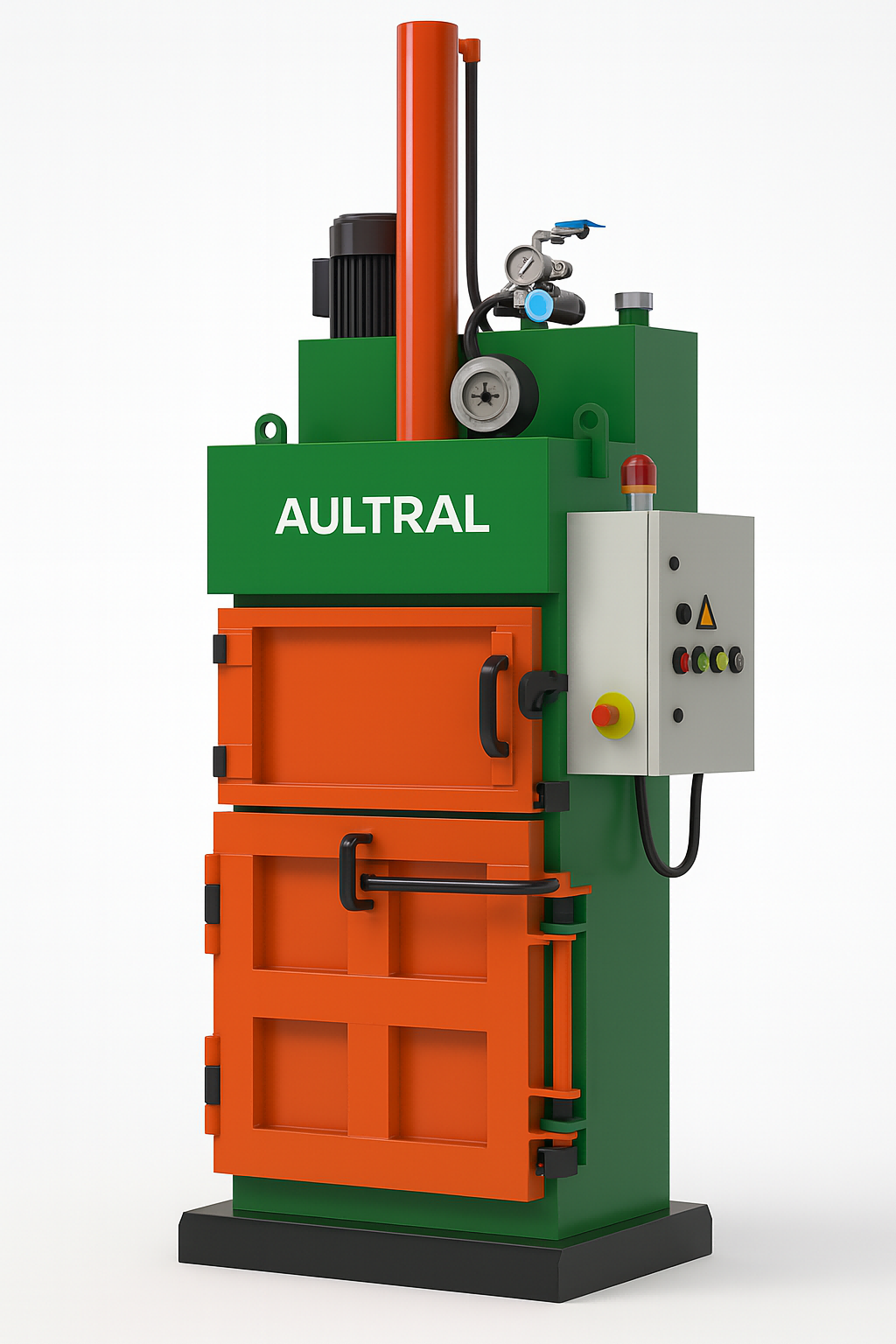

Understanding Vertical Balers

Vertical balers, also known as stand-up balers or downstroke balers, are compact hydraulic machines designed to compress recyclable materials into dense, manageable bales. Unlike horizontal balers, vertical balers load materials from the front and compress waste from the top down. They are particularly suitable for small to medium-sized facilities that handle moderate volumes of recyclable waste such as cardboard, paper, plastic film, textiles, aluminum cans, and even light metal scraps.

The core advantages of vertical balers include a smaller footprint, lower purchase and operating costs, and ease of installation and maintenance. These benefits make them an attractive solution for supermarkets, retail stores, warehouses, recycling centers, restaurants, manufacturing plants, and hospitals.

Key Applications Across Industries

-

Retail and Supermarkets

Large retail chains and supermarkets generate significant amounts of packaging waste, especially cardboard boxes and plastic wrap. Vertical balers are ideal for these environments because they can be installed in backrooms or storage areas to immediately compress packaging waste, reducing the need for frequent waste collection. -

Warehouses and Logistics Centers

Distribution hubs handle vast volumes of shipping materials daily. Vertical balers help compress these materials on-site, lowering disposal costs and freeing up valuable space. Baled waste is also easier to store and transport for recycling. -

Recycling and Waste Management Facilities

For companies in the recycling industry, vertical balers are a staple. They provide an efficient and economical way to process and store recyclables before they are sent for further treatment. Balers help increase the density of waste, which is critical for maximizing truckload efficiency. -

Food and Beverage Industry

Restaurants, hotels, and food processing plants often deal with waste such as plastic packaging, paper waste, and aluminum cans. Vertical balers help reduce the volume of waste and improve hygiene and cleanliness in the workplace. -

Textile and Apparel Industry

Textile factories and second-hand clothing shops use vertical balers to compress fabric scraps, old clothes, and other soft materials into compact bundles. This not only saves storage space but also eases logistics when exporting or selling used clothing in bulk. -

Hospitals and Institutions

Healthcare facilities are increasingly adopting balers to manage their non-hazardous waste, such as paper, plastic containers, and packaging materials. A tidy waste management system also contributes to better hygiene and efficiency.

Advantages That Drive Promotion

Promoting vertical balers effectively requires highlighting the following benefits to potential users:

-

Space-Saving Design: Vertical balers require less floor space compared to horizontal models, making them suitable for businesses with limited area.

-

Cost Efficiency: They have lower initial investment and operating costs, especially for businesses that do not require continuous high-capacity baling.

-

Ease of Operation: Most vertical balers are simple to operate with minimal training, reducing labor costs and downtime.

-

Environmental Compliance: By promoting recycling and reducing landfill contributions, vertical balers help companies meet environmental regulations and sustainability goals.

-

Revenue Opportunities: Compressed recyclables such as cardboard and plastic can be sold to recycling companies, providing additional income streams.

Market Promotion Strategies

To promote vertical balers effectively in both developed and developing markets, manufacturers and distributors should consider a multi-faceted approach:

-

Educational Marketing

Create informative content such as blog posts, videos, and case studies that explain how vertical balers work, their applications, and the return on investment. Educate customers on how balers can help them meet sustainability targets and cut waste management costs. -

Industry Trade Shows and Expos

Participating in waste management, recycling, and industrial equipment exhibitions can help showcase the machines directly to buyers. Live demos are especially impactful for demonstrating machine efficiency and bale quality. -

Local Distributors and Service Networks

Partnering with local agents ensures better customer support and accessibility in new markets. After-sales service, spare parts availability, and operator training are essential factors for customer trust and retention. -

Customization and Diversified Product Lines

Offer vertical balers in various sizes and capacities, from compact models for restaurants to heavy-duty units for recycling plants. Custom features like automatic bale ejection, safety interlocks, and PLC control panels can enhance user experience. -

Government and NGO Collaboration

In regions with growing environmental policies or recycling programs, working with government bodies or environmental NGOs can open opportunities for subsidies or bulk procurement projects. -

Social Media and E-commerce Platforms

Utilize platforms like Facebook, LinkedIn, and Alibaba to reach international buyers. Short videos showing baler operations and customer testimonials are highly effective on these platforms.

Conclusion

Vertical balers are essential tools in modern waste management, offering businesses across industries a reliable solution for reducing waste volume, improving workplace efficiency, and supporting environmental goals. As awareness of recycling and sustainability grows globally, the demand for vertical balers is expected to rise steadily. By understanding their practical applications and adopting smart promotion strategies, suppliers can tap into this growing market and build long-term customer relationships.