In today’s industrial and commercial world, effective waste management is more than a regulatory requirement—it’s a smart business strategy. Whether you operate a warehouse, retail chain, recycling facility, or manufacturing plant, the Vertical Baler is a game-changing solution that helps reduce waste volume, improve sustainability, and save operational costs.

This article dives deep into everything you need to know about vertical balers—what they are, how they work, where they’re used, their benefits, and how to choose the right one for your business.

What Is a Vertical Baler?

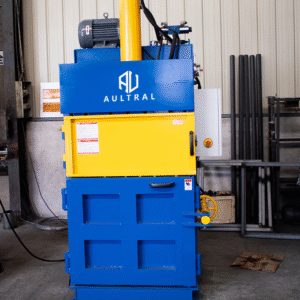

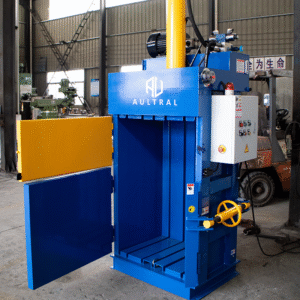

A Vertical Baler, also known as a stand-up baler or downstroke baler, is a type of waste compaction machine designed to compress recyclable materials such as cardboard, plastic film, paper, and even textiles into compact, manageable bales. It gets its name from the vertical motion of the compression platen, which moves downward to compress materials.

Unlike horizontal balers, which are larger and suitable for high-volume industrial use, vertical balers are typically more compact and cost-effective, making them ideal for small to medium-sized businesses.

How Does a Vertical Baler Work?

The working principle of a vertical baler is relatively simple yet highly efficient:

-

Loading: Waste materials are manually loaded into the baling chamber.

-

Compression: A hydraulic ram moves downward with immense force to compress the materials.

-

Strapping: Once the bale is formed, it’s tied manually with baling wire or strapping to maintain its shape.

-

Ejection: The compressed bale is ejected from the machine, ready for storage or transport to a recycling facility.

Most modern vertical balers are equipped with safety features, auto-return systems, and user-friendly control panels to ensure ease of operation and workplace safety.

Common Applications of Vertical Balers

Vertical balers are versatile and can be used across multiple industries. Here are some of the most common use cases:

-

Retail Stores: Compress packaging waste like cardboard boxes and plastic wraps.

-

Warehouses and Distribution Centers: Manage the large volume of recyclables that come with inventory management.

-

Supermarkets and Grocery Stores: Deal with food packaging and damaged goods.

-

Hotels and Restaurants: Reduce waste volume from food packaging, paper, and plastics.

-

Recycling Centers: Pre-process materials for efficient transportation and resale.

-

Textile Industries: Bundle used clothing and fabrics for reuse or recycling.

Key Benefits of Using a Vertical Baler

1. Space Saving

Vertical balers significantly reduce the volume of waste materials, freeing up valuable floor space that can be used for core operations.

2. Cost Reduction

By minimizing waste volume, businesses can reduce the frequency and cost of waste pickups. In some cases, recycled bales can even be sold to recycling companies for additional revenue.

3. Environmental Compliance

Using a baler helps businesses comply with environmental regulations and demonstrates a commitment to sustainable practices.

4. Improved Workplace Safety

Loose waste can create tripping hazards and fire risks. Balers help keep workspaces tidy and safe.

5. Operational Efficiency

With less time spent on managing waste, employees can focus more on productivity and core business tasks.

Types of Vertical Balers

Vertical balers come in various models and sizes depending on the type of material being processed and the required bale size:

-

Standard Cardboard Balers: Designed for corrugated boxes and paper waste.

-

Plastic Film Balers: Specialized for compressing soft plastics like stretch wrap and shrink film.

-

Textile Balers: Tailored for fabric and clothing waste.

-

Multi-material Balers: Versatile machines capable of handling mixed recyclable waste.

Some models may include advanced features such as automatic bale ejection, programmable controls, and remote monitoring.

How to Choose the Right Vertical Baler for Your Business

Selecting the best vertical baler depends on several key factors:

1. Type and Volume of Waste

Understand what kind of material you need to bale (cardboard, plastic, textiles, etc.) and estimate the daily or weekly volume.

2. Available Space

Measure your available floor space and ceiling height to ensure the baler fits comfortably in your workspace.

3. Bale Size and Weight

Choose a machine that produces bales compatible with your handling equipment (e.g., pallet jacks or forklifts).

4. Ease of Use

Look for features like automatic cycle start, intuitive control panels, and easy-to-replace baling wire.

5. Safety Features

Ensure the machine includes emergency stop buttons, interlocking doors, and overload protection.

6. Budget and ROI

While upfront cost is important, also consider the long-term savings in waste disposal, labor, and potential revenue from recycled bales.

Vertical Baler Maintenance Tips

Proper maintenance ensures your baler operates efficiently and safely:

-

Daily Cleaning: Remove debris and clean the baling chamber.

-

Lubrication: Regularly lubricate hydraulic components and moving parts.

-

Hydraulic Oil Check: Monitor oil levels and replace them according to the manufacturer’s schedule.

-

Safety Checks: Inspect emergency stops, door interlocks, and pressure gauges.

-

Professional Servicing: Schedule regular inspections from certified technicians.

Is a Vertical Baler Right for You?

If your business deals with a steady stream of cardboard boxes, shrink wrap, or any recyclable packaging waste, a vertical baler can pay for itself quickly. It’s ideal for businesses that:

-

Want to reduce waste disposal costs.

-

Need to improve space utilization.

-

Are committed to sustainability goals.

-

Require a compact, affordable, and efficient baling solution.

Final Thoughts

Investing in a Vertical Baler is more than just buying a piece of equipment—it’s a step toward operational efficiency, environmental responsibility, and cost optimization. With the right baler, you’ll not only manage your waste more effectively but also create a cleaner, safer, and more productive workspace.

If you’re ready to take control of your waste management system, a vertical baler could be the perfect solution. Reach out to us today to get a tailored recommendation based on your business needs.

Need help choosing a vertical baler?

📩 Contact our experts now for a free consultation and quote!