Introduction

In today’s world, where environmental sustainability and efficient waste management are critical, balers have become indispensable machines in various industries. A baler is a piece of equipment designed to compress and bind materials such as cardboard, paper, plastics, textiles, and metals into compact, manageable bales. These bales are easier to transport, store, and recycle, making balers essential in recycling facilities, manufacturing plants, retail operations, and agricultural settings.

This article explores the types of balers, their applications, technological advancements, and their impact on waste management and recycling efforts. By the end, readers will have a comprehensive understanding of how balers contribute to sustainability and operational efficiency.

Types of Balers

Balers come in different configurations, each suited for specific materials and operational needs. The main types include:

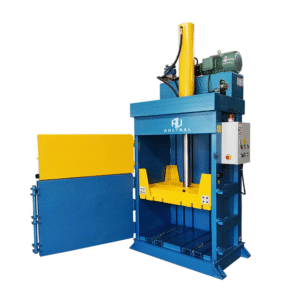

1. Vertical Balers

-

Best for: Small to medium businesses, retail stores, and warehouses.

-

How they work: Materials are loaded from the top, and a hydraulic press compresses them downward into a bale.

-

Advantages:

-

Space-efficient (takes up less floor space).

-

Lower initial cost compared to horizontal balers.

-

Ideal for businesses with moderate waste output.

-

-

Commonly used for: Cardboard, paper, and plastic film.

2. Horizontal Balers

-

Best for: Large-scale recycling centers, manufacturing plants, and distribution hubs.

-

How they work: Materials are fed horizontally into a compression chamber, where a ram compresses them into dense bales.

-

Advantages:

-

Higher capacity and faster processing.

-

Can produce larger, heavier bales (up to 2,000 lbs).

-

Automated feeding systems available for high-volume operations.

-

-

Commonly used for: Cardboard, metals, textiles, and industrial waste.

3. Two-Ram Balers (Closed-Door Balers)

-

Best for: Heavy-duty recycling of metals and dense materials.

-

How they work: Use two hydraulic rams for maximum compression, producing extremely dense bales.

-

Advantages:

-

Highest compression force.

-

Ideal for scrap metal recycling.

-

Reduces transportation costs due to higher density.

-

4. Specialty Balers

-

Agricultural Balers: Used for hay, straw, and crop residues (round or square bales).

-

Foam Balers: Compress foam materials (e.g., mattress recycling).

-

PET Balers: Specifically designed for plastic bottle recycling.

Key Applications of Balers

Balers play a crucial role in multiple industries by improving waste handling and recycling efficiency.

1. Recycling Industry

-

Cardboard & Paper Recycling: Supermarkets, warehouses, and offices use balers to compact OCC (Old Corrugated Cardboard) for resale.

-

Plastic Recycling: PET bottles and plastic film are baled for reprocessing.

-

Metal Recycling: Scrap metal balers help auto recyclers and metal processors reduce volume before melting.

2. Retail & E-Commerce

-

Large retailers like Walmart and Amazon rely on balers to manage packaging waste from shipments.

-

Reduces dumpster costs and improves sustainability compliance.

3. Manufacturing & Industrial Waste

-

Factories use balers to handle production waste, such as fabric scraps, rubber, and packaging materials.

-

Helps comply with environmental regulations by minimizing landfill contributions.

4. Agriculture

-

Farmers use hay balers to compact straw and hay for livestock feed and storage.

-

Reduces storage space and makes transportation more efficient.

Technological Advancements in Balers

Modern balers incorporate advanced features to improve efficiency, safety, and automation.

1. Automation & Smart Controls

-

Automatic Tying Systems: Reduce manual labor by automatically binding bales with wire or plastic straps.

-

IoT Integration: Some balers now include sensors to monitor compression force, bale weight, and maintenance needs.

-

Remote Monitoring: Operators can track performance via mobile apps, reducing downtime.

2. Energy Efficiency

-

Newer models use regenerative hydraulic systems that reduce energy consumption by reusing hydraulic fluid pressure.

-

Solar-powered balers are emerging in eco-conscious facilities.

3. Safety Features

-

Emergency Stop Systems: Prevent accidents during operation.

-

Lockout/Tagout Mechanisms: Ensure safety during maintenance.

-

Dust & Noise Reduction: Improved designs minimize workplace hazards.

4. AI & Machine Learning

-

Some high-end balers use AI to optimize compression based on material type.

-

Predictive maintenance alerts reduce unexpected breakdowns.

Economic and Environmental Benefits of Balers

1. Cost Savings

-

Reduced Waste Hauling Costs: Compact bales mean fewer trips to recycling centers.

-

Revenue from Recyclables: Many businesses sell baled cardboard, plastic, and metal to recyclers.

-

Lower Storage Costs: Bales take up less space than loose waste.

2. Environmental Impact

-

Reduces Landfill Waste: Balers help divert tons of recyclable materials from landfills.

-

Lowers Carbon Footprint: Fewer transport trips mean reduced fuel consumption and emissions.

-

Supports Circular Economy: Efficient baling makes recycling more viable, promoting reuse of materials.

Future Trends in Baler Technology

The future of balers includes:

-

Fully Autonomous Balers: Self-loading and self-tying machines.

-

Blockchain for Recycling Tracking: Ensuring transparency in waste management.

-

More Compact & Mobile Balers: For small businesses and urban recycling programs.

Conclusion

Balers are a cornerstone of modern waste management, offering economic, operational, and environmental benefits. As technology advances, they will become even more efficient, helping businesses and communities achieve zero-waste goals. Whether for recycling, retail, or agriculture, investing in the right baler can lead to significant cost savings and a greener future.

By understanding the different types, applications, and innovations in baler technology, industries can make informed decisions to optimize their waste management strategies.