In today’s fast-paced industrial and commercial environments, waste generation is inevitable — but smart, efficient, and sustainable waste handling is a choice. A choice that more and more businesses are making by turning to one of the most transformative pieces of equipment in the recycling and packaging industry: the Horizontal Fully Automatic Baler.

Whether you run a recycling facility, a logistics hub, a printing factory, or a packaging plant, handling large volumes of waste like cardboard, paper, plastic film, or textile scraps can be overwhelming without the right equipment. This is where horizontal fully automatic balers come into play — providing a hands-free, cost-effective, and space-saving solution that turns loose waste into tightly compressed, stackable bales.

In this article, we’ll break down exactly what a horizontal fully automatic baler is, how it works, its advantages over other types of balers, and why it’s becoming the go-to solution for smart waste management.

What Is a Horizontal Fully Automatic Baler?

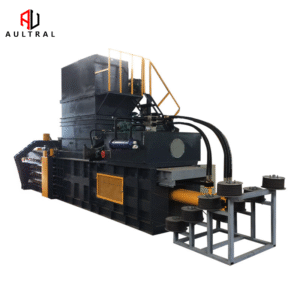

A horizontal fully automatic baler is a high-performance machine designed to compress large volumes of recyclable materials into dense bales using hydraulic pressure. Unlike vertical balers that require manual feeding and strapping, horizontal fully automatic balers are equipped with automatic feeding systems (often with conveyors), automatic tying mechanisms, and programmable logic controllers (PLC) for fully unattended operation.

Key components typically include:

-

Hydraulic system for powerful compression

-

Conveyor system for continuous feeding

-

Automatic wire tying mechanism for bale strapping

-

Control panel with PLC for intelligent operation

-

Chamber and pressing ram to form compact bales

Materials handled can include:

-

Corrugated cardboard (OCC)

-

Newspaper and mixed paper

-

PET bottles

-

Plastic film (LDPE, HDPE)

-

Straw, textile scraps, and more

How It Works: The Baling Process

-

Feeding: Materials are fed into the hopper either manually or via a conveyor belt.

-

Sensing: Sensors detect when the hopper is full and trigger the hydraulic cycle.

-

Compression: The hydraulic ram compresses the material horizontally in the baling chamber.

-

Strapping: Once the bale reaches a pre-set size, the machine automatically ties it using steel or plastic wire.

-

Ejection: The completed bale is pushed out and ready for transport or storage.

This fully automatic cycle minimizes labor, maximizes throughput, and ensures uniform bale sizes — which are easier to stack, transport, and sell.

Advantages of Horizontal Fully Automatic Balers

1. 💪 High Efficiency and Output

With automatic feeding and strapping, these machines can process tons of waste per hour. Ideal for operations with continuous waste flow.

2. 👷 Labor Saving

Manual strapping and supervision are eliminated. One operator can monitor multiple machines or perform other tasks, reducing labor costs significantly.

3. 📦 Uniform Bale Size

Automatic balers produce consistent bale dimensions and densities, which improves palletizing, storage efficiency, and transport optimization.

4. 🔧 Customizable

Machines can be tailored based on:

-

Bale size and weight

-

Material type

-

Feeding system

-

Tying method (horizontal or vertical wire tying)

5. 🌱 Sustainability

By compacting materials, businesses reduce landfill use and transportation emissions — contributing to greener operations and improved ESG (Environmental, Social, Governance) scores.

6. 🛠️ Durability and Low Maintenance

Modern horizontal balers are built for continuous operation and equipped with self-cleaning systems, overload protection, and remote diagnostics, ensuring long-term reliability.

Horizontal vs. Vertical Baler: What’s the Difference?

| Feature | Horizontal Fully Automatic Baler | Vertical Baler |

|---|---|---|

| Throughput | High (1-20+ tons/hour) | Low to medium |

| Operation | Fully automatic | Semi-manual |

| Feeding method | Conveyor or automatic hopper | Manual loading |

| Labor requirement | Minimal | Higher |

| Space requirement | Larger footprint | Smaller footprint |

| Bale consistency | High | Medium |

| Best for | Industrial-scale facilities | Small-scale operations |

If you’re running a warehouse that produces dozens of tons of waste per week, a vertical baler simply won’t cut it. Horizontal fully automatic balers are the industrial answer to serious waste volume.

Applications in Various Industries

-

Recycling Centers: For baling mixed recyclables, paper, cardboard, plastics.

-

Logistics & E-commerce: Deal with excessive cardboard boxes and packaging materials.

-

Printing & Packaging Plants: Large amounts of trim waste, paper offcuts, and plastic film.

-

Agricultural Processing: Compress straw, cotton, or corn stalks for easier transport or biomass production.

-

Textile Industry: Handle fabric scraps and offcuts efficiently.

What to Consider Before Buying

Before investing in a horizontal fully automatic baler, consider the following:

-

Material Type: Are you baling soft plastic, paper, or rigid materials like PET?

-

Throughput Requirement: Estimate your daily or hourly waste volume.

-

Space: These machines are long and require conveyor space; check your facility layout.

-

Bale Size & Weight: Match the bale dimensions to your transport and storage needs.

-

Budget: Prices vary widely based on automation level, capacity, and configuration.

Future Trends: Smart Balers for a Smarter Industry

The latest balers are becoming more intelligent, incorporating:

-

Remote monitoring and control

-

Predictive maintenance using IoT

-

Energy-saving hydraulic systems

-

Modular designs for easy upgrades

These advancements are transforming balers from simple compacting machines into smart waste management systems.

Final Thoughts

A Horizontal Fully Automatic Baler isn’t just a machine — it’s a strategic investment in operational efficiency, sustainability, and long-term cost savings. By automating the recycling and packaging process, businesses can free up valuable labor, reduce logistics costs, and move toward a greener, smarter future.

If your facility is drowning in waste material — cardboard, plastic, paper, or trim — it’s time to let a fully automatic baler do the heavy lifting.

💬 Ready to Optimize Your Waste Management?

Looking for a reliable horizontal baler supplier? Want to customize a baler to fit your specific needs? Contact us today — we offer tailored solutions, expert support, and high-efficiency balers that deliver real results.