Introduction

Every year, farms worldwide generate millions of tons of agricultural waste, including crop stalks (like wheat, rice, and corn straw) and tree branches from pruning. Instead of burning this biomass—which causes air pollution and soil degradation—modern recycling methods use shredders and balers to convert waste into fuel, fertilizer, and industrial raw materials.

This article explores how:

✅ Baling machines compress straw into dense blocks for storage and energy production.

✅ Shredders process branches into wood chips for fuel or compost.

✅ Farmers and biomass plants profit from this sustainable waste management approach.

The Problem with Agricultural Waste Burning

In many rural areas, farmers traditionally burn straw and branches after harvest, leading to:

🔥 Severe air pollution (smog, CO₂ emissions)

🔥 Loss of nutrients that could enrich soil

🔥 Fire hazards spreading to forests and villages

Governments are increasingly banning open burning, pushing farmers to adopt mechanical recycling solutions like shredding and baling.

How Baling Machines Transform Straw into Profit

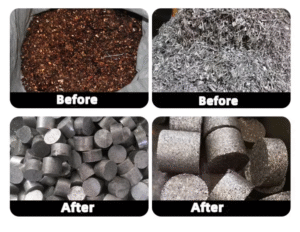

1. The Straw Baling Process

After harvest, leftover straw is scattered across fields. Instead of burning, farmers use:

-

Hay rakes to gather straw into rows.

-

Baling machines (round or square balers) to compress it into tight bundles (20-50 kg each).

Types of Straw Baling Machines

| Type | Best For | Bale Shape | Capacity |

|---|---|---|---|

| Round Baler | Small to mid-sized farms | Cylindrical | 10-20 bales/hour |

| Square Baler | Large farms, industrial use | Rectangular blocks | 30-50 bales/hour |

| High-Density Baler | Biomass power plants | Extra-compressed cubes | 5-10 tons/hour |

2. Uses for Baled Straw

-

Animal bedding (absorbs moisture, reduces odors)

-

Biomass fuel for power plants (replaces coal)

-

Mushroom cultivation (straw provides growth substrate)

-

Erosion control mats (used in construction)

3. Economic Benefits for Farmers

-

Selling straw bales to power plants earns $50-$150 per ton.

-

Reduces waste disposal costs (no need for burning permits).

-

Improves soil health when some straw is left as mulch.

How Shredders Process Branches into Useful Materials

1. The Wood Shredding Process

Pruned branches, orchard trimmings, and fallen trees are:

-

Fed into industrial shredders (with sharp rotating blades).

-

Reduced to 2-5 cm wood chips.

-

Sorted for different uses.

Types of Agricultural Shredders

| Type | Best For | Output Size | Power Source |

|---|---|---|---|

| Drum Shredder | Thick branches | 3-10 cm chips | Tractor PTO |

| Disk Shredder | Vineyards, orchards | 1-5 cm mulch | Electric/Diesel |

| Mobile Shredder | Forestry operations | Variable sizes | Truck-mounted |

2. Uses for Shredded Wood

-

Biomass fuel (for heating or electricity)

-

Organic fertilizer (mixed with manure to accelerate decomposition)

-

Landscaping mulch (retains soil moisture, prevents weeds)

-

Particleboard material (for furniture manufacturing)

3. Cost-Saving Advantages

-

Eliminates burning fines (up to $5,000 penalties in some regions).

-

On-site processing reduces transportation costs.

-

Self-sufficient energy if chips power farm boilers.

Case Study: China’s Straw Recycling Success

In Shandong Province:

-

1,200 straw baling stations were established.

-

Farmers earn $120 million annually selling bales.

-

CO₂ emissions dropped 30% in 5 years.

In Denmark:

-

70% of agricultural waste is shredded for district heating.

-

Saves 1.2 million tons of coal yearly.

Choosing the Right Equipment

For Straw Baling:

-

Small farms: Round baler (~$20,000)

-

Large operations: High-density square baler (~$80,000)

For Branch Shredding:

-

Orchards: PTO-driven drum shredder (~$15,000)

-

Forestry: Mobile diesel shredder (~$100,000)

The Future of Agricultural Waste Recycling

-

Smart Balers with IoT sensors to optimize bale density.

-

Biochar Production – Superheated shredded wood becomes carbon-rich fertilizer.

-

Government Incentives – Subsidies for farmers adopting recycling tech.

Conclusion: From Waste to Wealth

Shredders and balers turn agricultural “trash” into cash while protecting the environment. Farmers who invest in this technology:

✔ Earn extra income from waste sales

✔ Avoid burning penalties

✔ Contribute to circular economies

Whether you’re a smallholder or large agribusiness, recycling straw and wood waste is no longer optional—it’s essential for sustainable farming.