Introduction: Why The Alligator Shear Matters In Modern Recycling

In today’s metal recycling and fabrication industries, efficiency, safety, and precision are no longer optional—they are essential. As scrap volumes increase and material types become more diverse, companies need reliable equipment that can handle heavy-duty cutting while remaining easy to operate. This is where the Alligator Shear Machine, often called a Tiger Head Shear or Crocodile Shear, plays a critical role.

Known for its strong biting force and jaw-like cutting structure, the alligator shear is one of the most widely used machines for cutting scrap metal into manageable sizes. Whether you are running a recycling yard, steel processing facility, or metal fabrication workshop, understanding how this machine works—and how to choose the right model—can significantly improve productivity and profitability.

This guide will walk you through what an alligator shear machine is, why it is so valuable, how to use it safely and effectively, and how to select the best model for your needs.

What Is An Alligator Shear Machine?

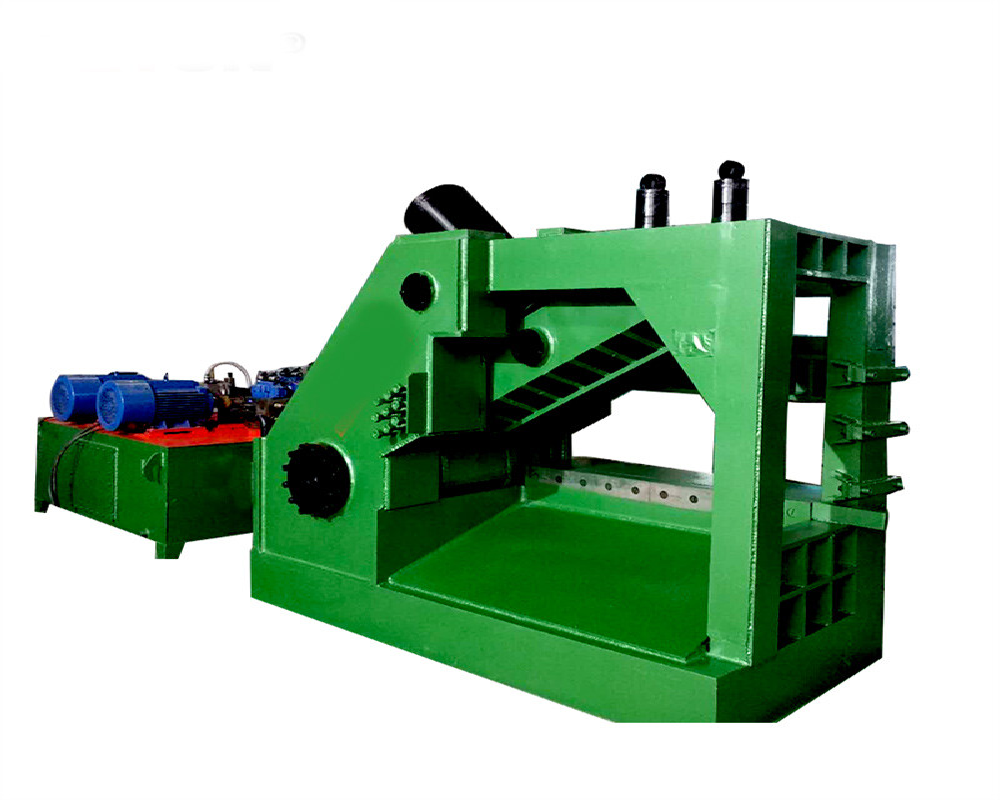

An Alligator Shear Machine is a hydraulic metal-cutting machine designed to cut long or bulky metal materials into shorter lengths. Its name comes from its distinctive structure: a fixed lower blade and a moving upper blade that opens and closes like an alligator’s mouth.

Unlike guillotine shears or saws, alligator shears are specifically built for irregular scrap materials. They can easily cut through steel bars, pipes, angles, channels, aluminum profiles, copper rods, and other non-ferrous metals.

Key Structural Components

- Hydraulic System – Provides powerful and stable cutting force

- Upper And Lower Blades – High-strength alloy steel blades designed for durability

- Pressing Arm (Optional) – Holds material firmly during cutting

- Motor And Pump Unit – Drives the hydraulic oil circulation

- Control System – Foot pedal or button control for safe operation

Because of their simple structure and strong performance, alligator shears are favored by small to medium-sized recycling operations as well as large industrial facilities.

How Does An Alligator Shear Machine Work?

The working principle of an alligator shear machine is straightforward yet highly effective.

- The operator places the metal material onto the cutting table.

- The material is positioned between the upper and lower blades.

- When the control is activated, the hydraulic cylinder drives the upper blade downward.

- The blades apply concentrated shear force, cutting the metal cleanly.

- The blade returns to its open position, ready for the next cut.

This open-mouth design allows for fast feeding and continuous operation, making it ideal for processing long scrap materials.

Why Choose An Alligator Shear Machine?

High Cutting Efficiency

Alligator shears are designed for rapid cutting cycles. Operators can process large volumes of scrap metal in a short amount of time, significantly improving throughput.

Wide Material Compatibility

From light aluminum profiles to thick steel bars, these machines handle a broad range of materials without frequent blade changes.

Compact And Space-Saving Design

Compared with gantry shears or large shredders, alligator shears occupy much less floor space, making them perfect for workshops with limited room.

Lower Investment Cost

For businesses that do not require extremely high tonnage cutting, alligator shears offer an excellent balance between performance and cost.

Easy Operation And Maintenance

With simple controls and a clear mechanical structure, operators can quickly learn how to use the machine, while routine maintenance remains minimal.

Common Applications Of Alligator Shear Machines

Alligator shear machines are widely used across multiple industries, including:

- Scrap metal recycling yards

- Steel structure fabrication workshops

- Non-ferrous metal processing plants

- Automotive dismantling facilities

- Construction and demolition waste processing

They are especially effective for cutting:

- Steel bars and rods

- Pipes and tubes

- Angle steel and H-beams (smaller sizes)

- Aluminum profiles

- Copper and brass materials

How To Use An Alligator Shear Machine Safely And Effectively

Step-By-Step Operating Guide

- Pre-Operation Inspection

Check hydraulic oil levels, blade condition, bolts, and electrical connections. - Material Placement

Place the metal material flat on the cutting table and align it with the blade. - Secure The Material

Use the pressing arm or manual positioning to prevent movement during cutting. - Activate The Cutting Cycle

Press the foot pedal or control button to start the cutting action. - Remove Cut Material

After the blade returns, remove the cut piece and prepare for the next cycle.

Safety Tips

- Always wear protective gloves and safety glasses

- Never place hands near the blade area

- Do not exceed the machine’s rated cutting capacity

- Perform regular blade sharpening and system checks

Safe operation not only protects workers but also extends the machine’s service life.

Key Technical Parameters To Understand

Before selecting or operating an alligator shear, it is important to understand its main specifications:

- Cutting Force (Tons) – Determines the maximum thickness and hardness of materials

- Blade Length – Affects cutting width and efficiency

- Cutting Capacity – Maximum size of steel or non-ferrous material

- Motor Power (kW) – Influences cutting speed and stability

- Operation Mode – Manual, foot pedal, or automatic control

These parameters directly impact performance and suitability for different applications.

How To Choose The Right Alligator Shear Model

Selecting the correct model is crucial for achieving optimal results. Here are some practical guidelines to help you make the right decision.

Consider Your Material Type

Different metals require different cutting forces. For example:

- Aluminum and copper need lower tonnage

- Carbon steel and rebar require higher cutting force

Always choose a model that exceeds your hardest material requirement.

Evaluate Material Size And Thickness

Check the maximum diameter or thickness of the materials you plan to process. The shear’s rated capacity should comfortably handle your largest scrap size.

Determine Daily Processing Volume

If you process large volumes daily, opt for a model with:

- Faster cutting speed

- Stronger hydraulic system

- Durable blades

For occasional use, a smaller model may be more cost-effective.

Check Power Supply Compatibility

Ensure the motor voltage and frequency match your local power standards to avoid additional modification costs.

Focus On Build Quality And Safety Features

High-quality steel frames, wear-resistant blades, and reliable hydraulic components will ensure long-term performance. Safety covers and emergency stop functions are also essential.

Alligator Shear Vs Other Metal Cutting Machines

Compared with other cutting solutions, alligator shears offer unique advantages:

- Vs Guillotine Shear: Better for irregular and long scrap materials

- Vs Band Saw: Faster cutting with less blade replacement

- Vs Shredder: Lower cost and simpler operation for length cutting

Choosing the right machine depends on your specific processing goals.

Maintenance And Service Tips

Regular maintenance keeps your alligator shear running smoothly:

- Replace hydraulic oil periodically

- Sharpen or replace blades when cutting efficiency drops

- Inspect seals and hoses for leaks

- Tighten bolts and check alignment regularly

Proper care can extend the machine’s lifespan by many years.

Conclusion: A Smart Investment For Metal Processing

The alligator shear machine is a powerful, efficient, and cost-effective solution for metal cutting and recycling. With its simple structure, strong cutting force, and wide application range, it remains one of the most trusted machines in the scrap metal industry.

By understanding how it works, how to use it safely, and how to choose the right model, businesses can maximize productivity while minimizing operational risks. If you are looking for a reliable metal cutting solution that delivers consistent results, the alligator shear machine is undoubtedly worth considering.

A well-chosen alligator shear is not just a machine—it is a long-term investment in efficiency, safety, and profitability.