What Is RDF (Refuse-Derived Fuel)?

RDF (Refuse-Derived Fuel) Is A More Processed And Refined Solid Fuel Compared To SRF (Solid Recovered Fuel). RDF Refers To A Standardized Fuel Product That Undergoes Advanced Physical Treatment, And Sometimes Thermal Or Biological Treatment, Resulting In A Highly Homogeneous Material With Specific Shapes (Pellets, Cylinders, Or Cubes) And Superior Combustion Properties. Its Particle Size Is Smaller (Typically <30mm), Moisture Content Lower (Typically <20%), And It Possesses Higher Energy Density And Better Handling Characteristics. RDF Is Suitable For Use In Specially Designed Commercial Or Industrial Combustion Plants. It Represents An Advanced Form Of Waste Valorization, Closer In Usability To Traditional Fossil Fuels, And Is A Top-Tier Solution For Efficient Waste-To-Energy Conversion.

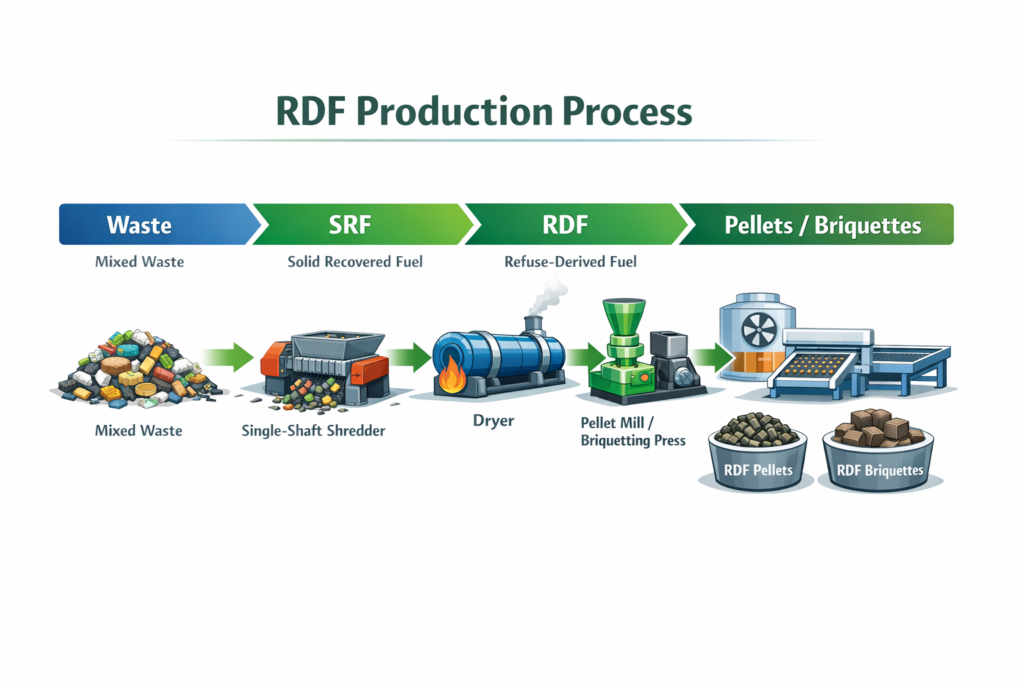

How Is Waste Converted To RDF?

The Production Of RDF Is A Refining And Densification Process Based On The SRF Production Line, With Additional Deep Processing Steps:

1. SRF Production Stage

The Process Begins By Following The Waste-To-SRF Method To Obtain Shredded Combustible Fragments (<100mm), Which Serve As The Raw Material For RDF.

2. Fine Shredding

The SRF Fragments Are Fed Into A Single-Shaft Fine Shredder For Further Size Reduction. This Shredder Uses High-Speed Rotating Knives Against Stationary Knives To Grind The Material Into A Finer, More Uniform Particle Size (<30mm Or Finer), Ideal For Subsequent Pelletizing.

3. Deep Drying (Critical Step)

The Finely Shredded Material Is Conveyed Into An RDF-Specific Dryer (Rotary Drum Dryer, Belt Dryer, Or Bio-Drying System). Using Hot Air (Sourced From Plant Excess Heat, Gas, Or Part Of The Produced Fuel), Moisture Is Reduced From >30-40% To Below 20%. This Step Significantly Increases Net Calorific Value And Stabilizes The Material.

4. Pelletizing / Briquetting

The Dried Low-Moisture Powder Is Fed Into An RDF Pellet Mill Or Briquetting Press. Under High Pressure, And Sometimes Heat, The Material Is Extruded Through A Die To Form Dense Pellets, Cylinders, Or Cubes. This Process Increases Energy Density, Improves Transport And Storage, And Provides Uniform Shape And Combustion Characteristics.

5. Cooling And Screening

The Hot RDF Pellets Are Cooled In A Cooler And Then Passed Over A Vibrating Screen To Separate Finished Product From Fines (Which Are Recycled), Ensuring Final Product Quality.

Key Equipment For RDF Production

Single-Shaft Fine Shredder

For Precision Shredding Of SRF To Create Ideal Particle Size Distribution For Drying And Pelletizing.

RDF Dryer

Core Upgrading Equipment. Typically An Indirectly Or Directly Heated Rotary Drum Dryer That Efficiently Reduces Moisture And Enhances Net Calorific Value.

RDF Pellet Mill / Briquetting Press

Core Densification Unit. Includes Ring-Die Pellet Mills, Flat-Die Pellet Mills, Or Hydraulic Briquetting Presses. Forms Dense, Durable Fuel Pellets Or Briquettes Under High Pressure.

Cooling And Screening System

Counter-Flow Cooler For Cooling Hot Pellets And Vibrating Screen For Grading To Ensure Uniform Product Size.

Upstream Support System

Includes Complete SRF Preparation Line Equipment (Air Separator, Dual-Shaft Shredder, Etc.), Hot Air Generator, Dust Removal, And Automated Control Systems.

Waste-To-RDF Solutions

Standard RDF Pelletizing Line

Core Process: “SRF Production + Fine Shredding + Thermal Drying + Ring-Die Pelletizing.” Produces Cylindrical Pellets With Excellent Market Acceptance For Most Dedicated Combustion Units.

RDF Briquetting Line

For Clients Requiring Larger Fuel Blocks (To Replace Coal In Fluidized Bed Boilers), Provides Production Line Centered On A Hydraulic Briquetting Press, Producing High-Density Fuel Cubes.

Modular Integration Solution

RDF Production Line Can Be Integrated As A Module Into Existing MBT Or Large MRF Facilities, Directly Upgrading Sorting Residues Into High-Value Commodities, Significantly Enhancing Project Economics And Resource Recovery Rate.

Customized Fuel Solution

Based On Specific Client Requirements (Calorific Value, Sulfur Content, Ash Melting Point), Pre-Treatment Intensity, Drying Parameters, And Forming Process Can Be Adjusted To Produce “Tailor-Made” Specialty Fuels.

Advantages Of RDF As A Sustainable Fuel

RDF Offers Numerous Advantages Over Traditional Fossil Fuels And Even Conventional Waste-Derived Fuels. One Of The Most Significant Benefits Is Its High Energy Density, Which Allows For More Efficient Storage, Transportation, And Combustion. The Low Moisture Content And Uniform Particle Size Reduce Handling Issues And Improve Combustion Stability, Leading To More Consistent Energy Output And Lower Emissions.

Additionally, RDF Contributes Directly To Waste Reduction, Diverting Materials From Landfills And Preventing Soil And Water Contamination. By Recovering Energy From Municipal Solid Waste And Industrial Residues, RDF Supports A Circular Economy Model, Turning Waste Streams Into Valuable Resources. Its Production Also Minimizes The Volume Of Ash And Non-Combustible Residues Compared To Direct Incineration, Simplifying Post-Combustion Management.

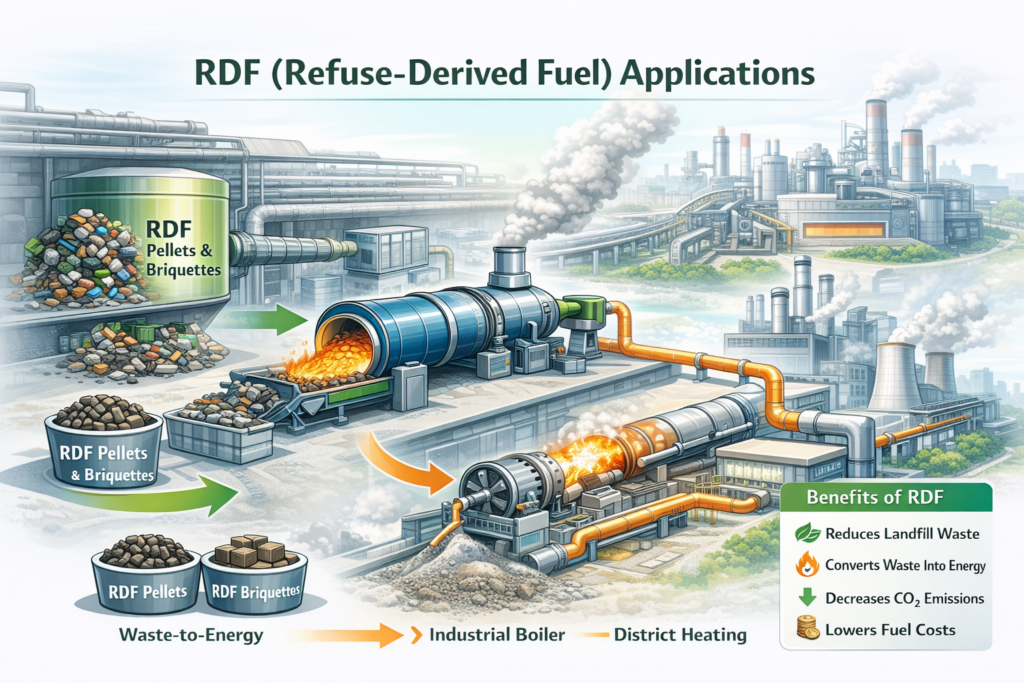

Applications Of RDF In Industrial And Commercial Sectors

RDF Can Be Used In A Wide Range Of Industrial And Commercial Combustion Systems. Many Power Plants Designed For Waste-To-Energy Conversion Can Directly Burn RDF Pellets Or Briquettes, Either As A Primary Fuel Or As A Supplement To Coal, Biomass, Or Other Fuels. Industries Such As Cement Manufacturing, Pulp And Paper, Steel Production, And Ceramic Manufacturing Benefit From RDF’s Stable Energy Output And Predictable Combustion Properties.

Fluidized Bed Boilers And Rotary Kilns Particularly Benefit From High-Density RDF Briquettes, Which Maintain Structural Integrity During Handling And Burning. Additionally, Smaller-Scale Industrial Boilers Can Utilize RDF Pellets To Replace Traditional Fossil Fuels, Reducing Fuel Costs And Carbon Emissions. The Flexibility Of RDF Shapes, Including Pellets, Cylinders, And Cubes, Allows Easy Integration Into Existing Fuel Feeding Systems Without Major Modifications.

Environmental And Economic Impact

From An Environmental Perspective, RDF Plays A Key Role In Reducing Greenhouse Gas Emissions. By Converting Plastic, Paper, And Other Combustible Waste Into Fuel, RDF Decreases Methane Emissions From Landfills And Reduces Dependence On Non-Renewable Fossil Fuels. The Use Of RDF In Industrial Processes Can Reduce Carbon Footprints, Particularly When Combined With Efficient Combustion Systems And Emissions Control Technologies.

Economically, RDF Represents A Valuable Revenue Stream From Previously Discarded Waste Materials. Facilities That Produce RDF Can Monetize Residues From Municipal Or Industrial Sorting Lines, While End Users Benefit From A Lower-Cost, Stable Fuel Source Compared To Coal Or Heavy Fuel Oil. The Modular Nature Of RDF Production Lines Allows For Gradual Investment, Making It Attractive For Both Large-Scale Waste-To-Energy Projects And Smaller Industrial Applications.

Market Potential And Global Trends

The Demand For RDF Is Increasing Globally, Driven By Stringent Waste Management Regulations, Circular Economy Initiatives, And Rising Energy Prices. Countries With Limited Landfill Space Or Strong Renewable Energy Targets See RDF As A Strategic Solution For Sustainable Energy Production. In Europe, Asia, And North America, RDF Is Becoming A Standard Fuel Option In Dedicated Combustion Facilities And Industrial Boilers.

Recent Advances In Sorting Technology, Drying Systems, And Pelletization Equipment Have Further Improved The Quality And Consistency Of RDF, Making It Competitive With Traditional Fossil Fuels. Additionally, Governments And Environmental Agencies Are Encouraging Waste Valorization Through Incentives, Carbon Credits, And Renewable Energy Certificates, Which Increase The Financial Viability Of RDF Projects.

Future Developments And Innovation Opportunities

The Future Of RDF Lies In Process Optimization, Integration With Renewable Energy Systems, And Material Diversification. Research Is Ongoing Into Advanced Pre-Treatment Methods, Such As Automated Sorting, Chemical Stabilization, And Bio-Drying, To Improve Fuel Quality And Reduce Contaminants. Combining RDF Production With Other Waste Management Systems, Like Mechanical-Biological Treatment (MBT) Plants, Enhances Resource Recovery And Maximizes Environmental Benefits.

Technological Innovations Include Continuous Pelletizing Systems, Energy-Efficient Dryers, And Smart Process Control Systems That Monitor Moisture, Particle Size, And Calorific Value In Real Time. These Innovations Improve Plant Efficiency, Reduce Operational Costs, And Ensure High-Quality Output. Additionally, Developing RDF With Specialized Properties, Such As Low-Sulfur Or High-Calorific Pellets, Opens New Markets In High-Performance Industrial Applications.

Conclusion

RDF Represents A Transformative Approach To Waste Management And Energy Production. By Converting Municipal And Industrial Waste Into A High-Value, Standardized Fuel, RDF Offers Environmental, Economic, And Operational Advantages. With Proper Design, Advanced Equipment, And Optimized Processing, RDF Can Serve As A Reliable Alternative To Fossil Fuels While Supporting Circular Economy Goals. As Global Waste Generation Continues To Increase, RDF Will Play An Ever More Critical Role In Achieving Sustainable Energy Solutions And Maximizing The Value Of Waste Resources.