In the modern recycling industry, metal waste management plays a critical role in improving resource efficiency, reducing transportation costs, and supporting sustainable development. A Metal Baler is a powerful industrial machine designed to compress various types of metal scrap into dense, compact bales. By significantly reducing volume and improving handling efficiency, metal balers have become essential equipment for recycling plants, scrap yards, and manufacturing facilities around the world.

This article explains what a metal baler is, why it is important, and how to use it effectively in real industrial applications.

What Is A Metal Baler

A Metal Baler, also known as a metal baling press, is a hydraulic machine used to compress loose metal scrap into uniform, high-density bales. These bales are easy to store, transport, and process further, making metal recycling more economical and efficient.

Basic Working Principle

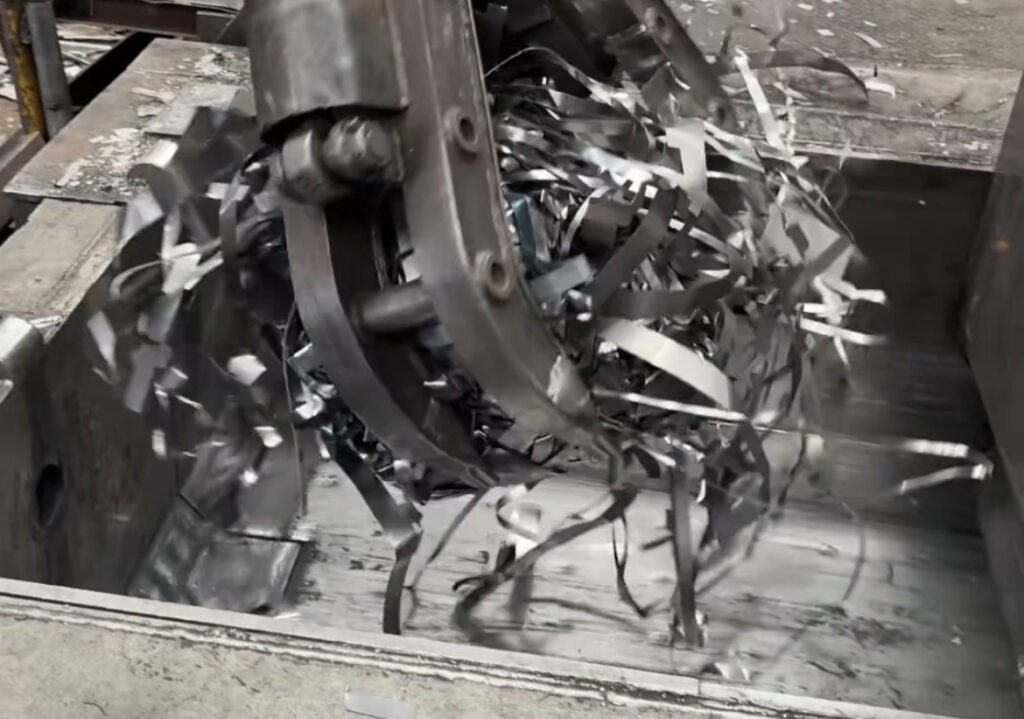

The metal baler operates using a high-pressure hydraulic system. Metal scrap is loaded into the compression chamber, where one or more hydraulic cylinders apply powerful force to compress the material. Once the preset bale size and density are achieved, the bale is ejected automatically or semi-automatically, depending on the machine configuration.

Metal balers are available in vertical, horizontal, and triple-compression designs, allowing users to choose the most suitable model for their specific material type and processing capacity.

Common Materials Processed

Metal balers are widely used to process:

-

Steel scrap and sheet metal

-

Aluminum cans and profiles

-

Copper wires and pipes

-

Stainless steel offcuts

-

Auto body panels and light metal structures

By adjusting compression force and chamber size, one metal baler can handle multiple metal types efficiently.

Why Choose A Metal Baler

Investing in a metal baler is a strategic decision for businesses involved in recycling, metal processing, and waste management.

Volume Reduction And Cost Savings

Loose metal scrap occupies large storage areas and results in high transportation costs. A metal baler can reduce the volume of scrap by up to 90%, allowing more material to be loaded into trucks or containers.

This directly lowers logistics costs and improves profitability for recycling companies.

Improved Recycling Efficiency

Compressed metal bales are easier to handle, stack, and feed into downstream recycling equipment such as shredders, shears, or furnaces. This improves overall workflow efficiency and reduces material handling time.

Labor And Safety Benefits

Using a metal baler reduces manual handling of sharp and heavy metal scraps. Modern balers are equipped with safety interlocks, emergency stop systems, and PLC controls, ensuring safer operation and reduced risk of workplace injuries.

Higher Scrap Value

Uniform, high-density bales are preferred by steel mills and smelters. Properly baled metal scrap often achieves higher market value compared to loose or irregular scrap, helping operators maximize returns.

Key Applications Of Metal Balers

Scrap Yards And Recycling Centers

Scrap yards generate large volumes of mixed metal waste daily. Metal balers help organize and process this material efficiently, saving space and improving shipment quality.

Manufacturing And Fabrication Plants

Metal offcuts and production waste can be baled immediately at the source, keeping workshops clean and organized while reducing disposal frequency.

Automotive Dismantling Facilities

After vehicles are dismantled, body panels and light metal parts can be compacted into dense bales for easier transport and further processing.

How To Use A Metal Baler

Correct operation ensures safety, consistent bale quality, and long machine life.

Step One: Installation And Preparation

The metal baler should be installed on a solid, level foundation. Hydraulic oil, electrical connections, and safety systems must be checked before startup. Operators should receive proper training and understand emergency procedures.

Step Two: Material Loading

Metal scrap is loaded into the compression chamber manually, by conveyor, or using a crane. Materials should be evenly distributed to ensure uniform compression and prevent mechanical stress.

Large or rigid items may require pre-cutting to improve baling efficiency.

Step Three: Compression Process

Once the chamber is filled, the operator activates the compression cycle. The hydraulic ram applies pressure, gradually compacting the metal scrap. Some machines use multi-directional compression to achieve higher bale density.

The compression parameters can be adjusted based on material type and desired bale size.

Step Four: Bale Ejection And Handling

After compression, the finished bale is ejected automatically or with operator assistance. The bale can then be stored, stacked, or loaded for transportation using forklifts or cranes.

Regular inspection of bale shape and density ensures consistent quality.

Maintenance And Daily Operation Tips

Routine Inspection

-

Check hydraulic oil level and temperature

-

Inspect hoses and seals for leaks

-

Ensure electrical components function properly

Scheduled Maintenance

-

Replace hydraulic oil according to manufacturer guidelines

-

Lubricate moving parts regularly

-

Inspect cylinders, guides, and wear plates

Proper maintenance minimizes downtime and extends equipment lifespan.

How To Choose The Right Metal Baler

Selecting the correct metal baler depends on several factors:

-

Type and thickness of metal scrap

-

Daily processing volume

-

Required bale size and weight

-

Available space and power supply

Consulting with an experienced manufacturer ensures the baler is correctly sized and configured for your operation.

Environmental And Economic Benefits

Metal balers support sustainable development by improving recycling rates and reducing energy consumption during transportation and processing. Efficient metal recycling conserves natural resources and reduces environmental impact.

At the same time, compacted scrap reduces storage requirements and operating costs, making metal balers a smart long-term investment.

Common Mistakes To Avoid When Using A Metal Baler

To achieve optimal performance and long service life, operators should avoid several common mistakes during daily operation. Overloading the compression chamber with oversized or excessively thick metal can cause uneven pressure distribution and increase wear on hydraulic components. Mixing incompatible materials, such as heavy solid blocks with light scrap, may also reduce bale quality.

Neglecting regular maintenance is another frequent issue. Insufficient hydraulic oil, worn seals, or loose electrical connections can lead to unexpected downtime and safety risks. Operators should always follow the manufacturer’s maintenance schedule and use recommended spare parts.

Finally, improper operator training can significantly impact efficiency and safety. Ensuring that all operators understand correct loading procedures, emergency stop functions, and basic troubleshooting will help maintain stable operation and maximize the overall value of the metal baler.

Conclusion: A Reliable Tool For Modern Metal Recycling

A Metal Baler is an essential machine for any business involved in metal recycling or waste management. By reducing volume, improving handling efficiency, and increasing scrap value, metal balers help companies operate more safely, efficiently, and profitably.

Whether used in scrap yards, factories, or recycling plants, a high-quality metal baler provides long-term value and supports sustainable industrial growth.