What Is An Iron Drum Flattening Machine?

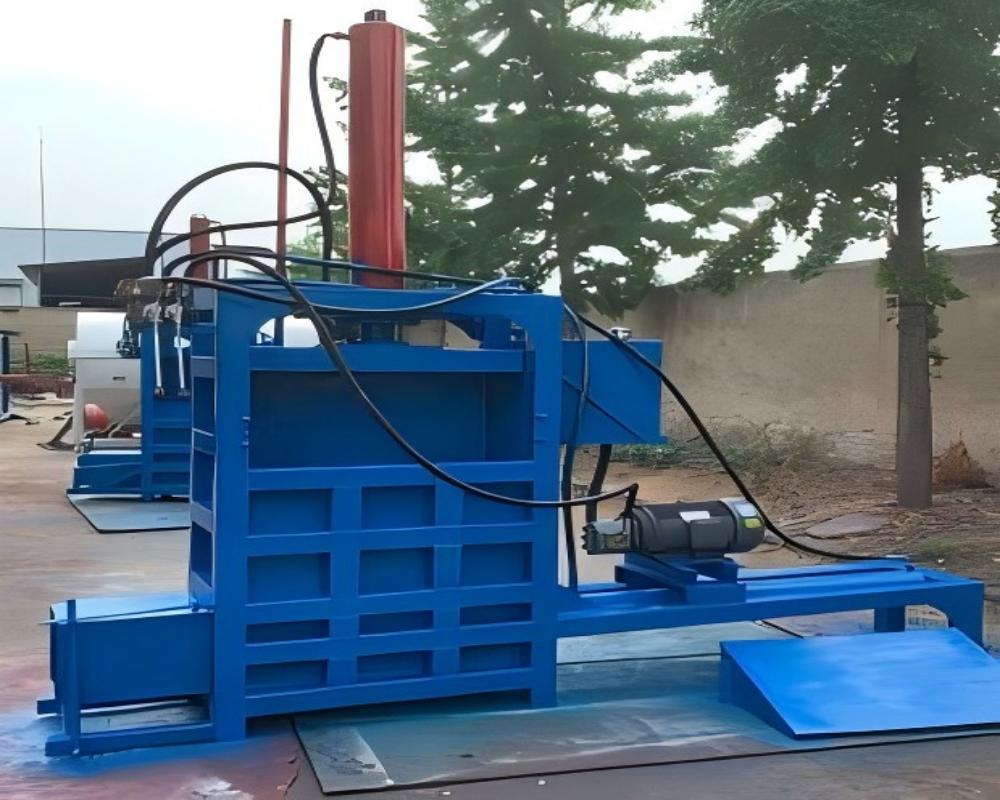

An Iron Drum Flattening Machine, also known as an Iron Drum Crusher or Drum Compactor, is an industrial machine designed to compress and flatten empty steel drums into a compact form. These drums are commonly used to store chemicals, oils, paints, and other industrial liquids. After use, they occupy a large amount of space and can be difficult and costly to handle.

By applying strong hydraulic or mechanical pressure, the iron drum flattening machine reduces the volume of steel drums significantly, making them easier to store, transport, and recycle. This machine is widely used in factories, recycling centers, warehouses, and hazardous waste treatment facilities.

Why Iron Drum Flattening Machines Are Essential In Modern Industry

Reducing Storage Space And Transportation Costs

Empty steel drums are bulky. Without compression, they take up excessive warehouse space and increase transportation costs. A drum flattening machine can reduce drum volume by up to 80–90%, allowing companies to store more drums in less space and transport them more efficiently.

Improving Workplace Safety

Uncompressed drums can roll, tip over, or leak residual substances, posing safety risks. Flattened drums are stable and easier to stack, significantly reducing the risk of accidents, injuries, and chemical exposure in the workplace.

Supporting Environmental Protection And Recycling

Steel drums are highly recyclable, but recycling becomes inefficient if drums are not processed properly. By flattening drums before recycling, companies improve recycling efficiency, reduce carbon emissions from transportation, and comply with environmental regulations.

Meeting Compliance And Waste Management Regulations

Many industries are subject to strict waste disposal and environmental laws. Using an iron drum flattening machine helps businesses meet compliance requirements by ensuring proper handling and disposal of industrial containers.

How An Iron Drum Flattening Machine Works

Hydraulic Compression System

Most modern iron drum flattening machines use a hydraulic system. A hydraulic cylinder applies downward pressure on the drum, gradually compressing it into a flat or pancake-like shape. Hydraulic systems provide strong, stable, and controllable force, making them ideal for heavy-duty applications.

Drum Loading And Positioning

The drum is placed vertically or horizontally into the crushing chamber, depending on the machine design. Some models include guide rails or positioning plates to ensure accurate and safe placement.

Crushing And Flattening Process

Once the machine is activated, the compression plate moves downward, crushing the drum evenly. Any remaining liquid residue can be collected through a drainage system, if equipped.

Discharge And Collection

After flattening, the compressed drum is removed manually or automatically. Advanced models may include automatic discharge systems to improve productivity and reduce labor effort.

Key Applications Of Iron Drum Flattening Machines

Manufacturing And Industrial Plants

Factories that consume large quantities of lubricants, chemicals, or raw materials often generate empty steel drums daily. A drum flattening machine helps manage this waste efficiently.

Recycling And Waste Processing Centers

Recycling facilities use these machines to prepare steel drums for shredding, melting, or resale as scrap metal.

Chemical And Hazardous Waste Facilities

In environments where drums contain hazardous residues, flattening machines with sealed or controlled systems help ensure safe processing.

Logistics And Warehousing Operations

Warehouses benefit from reduced storage requirements and improved organization by compressing empty drums on-site.

Advantages Of Using An Iron Drum Flattening Machine

High Efficiency And Time Savings

Manual handling of steel drums is slow and labor-intensive. An automated or semi-automatic flattening machine significantly increases processing speed and reduces labor costs.

Strong And Durable Construction

Most iron drum flattening machines are made of heavy-duty steel, ensuring long service life even under continuous industrial use.

Easy Operation And Maintenance

Designed for industrial users, these machines feature simple control systems and require minimal maintenance, reducing downtime.

Customizable Options

Manufacturers often offer customization, such as different compression forces, chamber sizes, or safety features, to meet specific customer needs.

How To Choose The Right Iron Drum Flattening Machine

Selecting the right model is crucial for performance and cost efficiency. Below are key factors to consider.

Drum Size And Type

Consider the size and material of the drums you handle:

-

Standard 200-liter steel drums

-

Smaller or larger industrial containers

-

Closed-head or open-head drums

Ensure the machine is compatible with your drum specifications.

Compression Force And Capacity

Different models offer different crushing forces, usually measured in tons. Choose a machine with sufficient force to flatten your drums completely without overloading the system.

Processing Volume And Throughput

Evaluate how many drums you need to process per day or per shift. For high-volume operations, an automatic or high-capacity model is recommended.

Power Supply And Energy Consumption

Check whether the machine operates on:

-

Single-phase or three-phase electricity

-

Hydraulic or electro-hydraulic systems

Energy efficiency is an important factor for long-term operational costs.

Safety Features

Look for machines with:

-

Emergency stop buttons

-

Safety guards or enclosures

-

Stable base structures

Safety compliance is essential, especially in industrial environments.

Installation Space And Footprint

Measure your available workspace and ensure the machine fits comfortably without disrupting workflow.

Manual Vs Automatic Iron Drum Flattening Machines

Manual Or Semi-Automatic Models

These are suitable for small to medium operations. They require more operator involvement but are cost-effective and easy to maintain.

Fully Automatic Models

Ideal for large-scale recycling or industrial plants, automatic machines offer higher efficiency, reduced labor input, and consistent output.

Maintenance Tips For Long-Term Performance

-

Regularly inspect hydraulic hoses and seals

-

Keep the crushing chamber clean

-

Lubricate moving parts as recommended

-

Check electrical connections periodically

Proper maintenance ensures stable performance and extends machine lifespan.

Why Invest In An Iron Drum Flattening Machine?

An iron drum flattening machine is not just a piece of equipment—it is an investment in efficiency, safety, and sustainability. By reducing waste volume, lowering operational costs, and supporting environmental responsibility, this machine delivers long-term value for businesses across multiple industries.

Conclusion: A Smarter Way To Handle Steel Drum Waste

As industries continue to focus on efficiency and environmental responsibility, the Iron Drum Flattening Machine has become an essential tool in modern waste management. Whether you operate a factory, recycling center, or warehouse, choosing the right drum flattening solution can dramatically improve your operations.

If you are looking for a reliable, efficient, and durable solution to handle steel drum waste, an iron drum flattening machine is a smart and future-proof choice.