Introduction

In the metal recycling industry, efficiency and cost control determine how competitive a business can be. However, investing in brand-new machinery isn’t always necessary. A second-hand metal baler offers nearly the same performance and durability as a new one but at a much lower price. Beyond the savings, used balers also support environmental sustainability and help recycling companies operate more responsibly.

This article explores why using a second-hand metal baler is a smart decision, how to operate and maintain it effectively, the benefits it brings to both businesses and society, and practical tips for choosing the right model for your needs.

Why Choose A Second-Hand Metal Baler

1. Significant Cost Savings

Purchasing a used metal baler can save up to 50–70% compared to a new unit. For startups or small recycling plants, this means lower upfront investment while still enjoying excellent compression power and reliability.

2. Proven Durability

High-quality metal balers are built with robust steel structures and long-lasting hydraulic systems. A well-maintained second-hand machine often performs just as effectively as new ones, making it a safe and dependable choice.

3. Quick Delivery And Setup

Used balers are typically ready for immediate shipment, allowing businesses to expand production without waiting months for new manufacturing and delivery.

4. Environmentally Responsible Choice

Reusing machinery is itself an act of recycling. It reduces industrial waste, conserves resources, and minimizes carbon emissions, aligning with the global push toward sustainability.

How To Operate A Second-Hand Metal Baler

1. Pre-Operation Checks

Before using the machine, ensure it’s on a flat, stable surface. Check hydraulic oil levels, inspect hoses and joints for leaks, and verify that all safety guards and emergency buttons function properly.

2. Feeding Materials

Load scrap metal such as aluminum, copper, or steel into the feeding chamber. Avoid overloading and remove any non-metal materials to prevent machine damage.

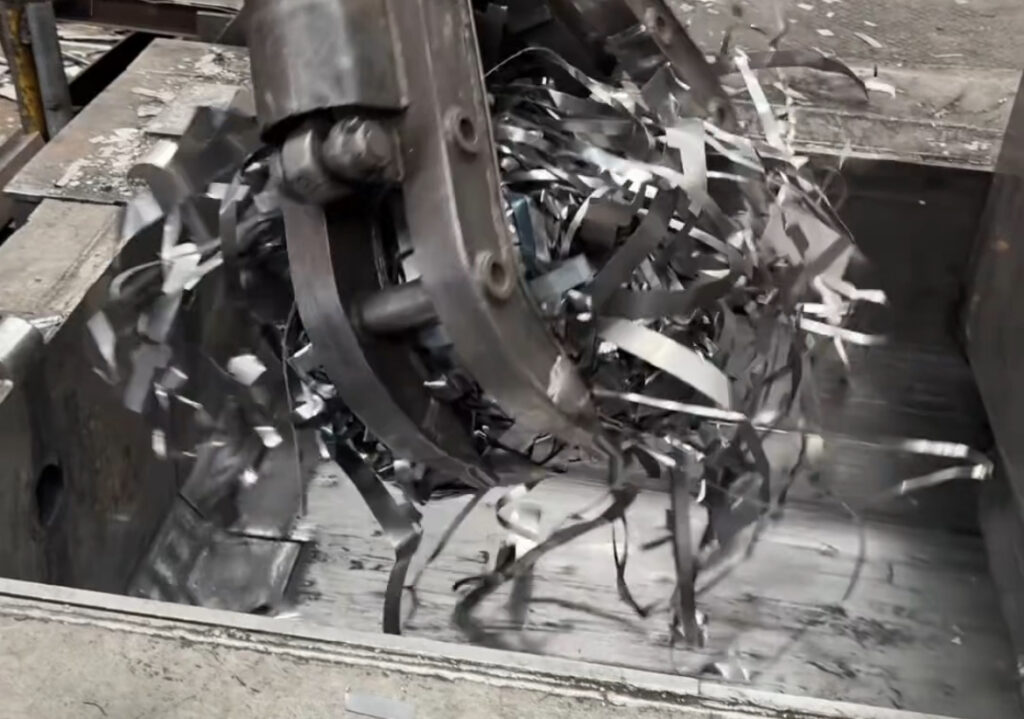

3. Compression Process

Close the chamber door securely, then start the hydraulic compression cycle. The main cylinder exerts pressure, compressing loose scrap into dense, high-value bales ready for transport.

4. Ejecting The Bale

Once compression is complete, open the chamber and use the hydraulic pusher or ejector system to remove the finished bale. Label and store bales properly for shipment.

Maintenance Tips To Extend Machine Life

A second-hand machine can last for many years if maintained properly. Follow these simple but crucial steps:

1. Keep The Machine Clean

Remove dust, metal chips, and oil residues after every work shift. A clean baler prevents corrosion and ensures smoother operation.

2. Regular Lubrication

Lubricate all moving parts and hinges regularly with high-quality grease. This minimizes wear and improves hydraulic performance.

3. Inspect Hydraulic Oil

Check oil levels weekly and replace the hydraulic oil every six months. Dirty or low-quality oil can damage seals and cylinders.

4. Tighten Bolts And Connections

Vibration during operation may loosen bolts. Inspect all fasteners, hose fittings, and electrical terminals regularly to prevent accidents.

5. Professional Servicing

Even if everything appears normal, schedule an expert inspection every 6–12 months. Preventive maintenance always costs less than major repairs.

Benefits For Businesses And Society

1. Enhances Recycling Efficiency

A metal baler compresses loose scrap into compact bales, saving space and making transportation and smelting more efficient. This improves productivity and lowers logistics costs.

2. Improves Profitability

Dense bales sell at higher market prices, as they are easier to store and handle. A used machine provides the same profitability potential as new equipment but with lower capital costs.

3. Promotes Sustainability

Using second-hand machinery and recycling scrap metal both contribute to resource conservation and environmental protection. It’s a complete cycle of reuse — metal and machinery alike.

4. Supports Small And Medium Enterprises

Second-hand balers allow smaller recyclers and local scrapyards to enter the recycling industry affordably, improving regional waste management and economic growth.

How To Choose The Right Used Metal Baler

When selecting a second-hand metal baler, consider the following important factors:

1. Type Of Baler

-

Vertical Metal Baler: Compact, easy to operate, ideal for limited spaces and small-scale recycling.

-

Horizontal Metal Baler: Designed for high-volume operations with automatic feeding and higher compression force.

2. Compression Force

Choose based on the material type. For lightweight materials like aluminum cans, 40–80 tons is sufficient; for heavy steel scrap, 120–200 tons or more may be required.

3. Bale Size And Density

Select a machine that produces bales fitting your transport and storage systems. Higher bale density means better market value.

4. Motor Power And Hydraulic System

Ensure compatibility with your factory’s voltage (220V, 380V, etc.). Prefer machines equipped with pure copper motors for stronger power and lower maintenance.

5. Supplier Credibility

Always buy from reliable suppliers who provide inspection reports, test videos, and after-sales support. A trusted seller ensures the machine’s quality and transparency.

Global Market Trends And Future Outlook

In recent years, the global demand for scrap metal recycling has grown rapidly due to the rising cost of raw materials and stricter environmental regulations. Governments and manufacturers worldwide are promoting circular economy policies, encouraging companies to recycle more and waste less.

At the same time, the availability of reliable second-hand recycling equipment has made it easier for developing regions — such as Southeast Asia, Africa, and South America — to build their recycling infrastructure. A used metal baler provides a low-risk, high-return entry point for these markets.

Looking forward, the market for refurbished and reconditioned recycling machines is expected to expand steadily. Many reputable manufacturers now offer certified used balers that undergo full inspection, repair, and testing before resale. This trend ensures that businesses can acquire quality equipment while contributing to global sustainability goals.

Conclusion

As global industries move toward a greener and more circular economy, the demand for efficient metal recycling solutions continues to grow. Companies that invest in used metal baler machines today are positioning themselves at the forefront of this transition. These machines not only help maximize resource recovery but also align with the increasing expectations of environmentally conscious customers and partners.

Investing in a second-hand metal baler is a smart and sustainable business decision. It reduces costs, boosts recycling efficiency, and supports global environmental goals. With proper operation and regular maintenance, a used baler can serve reliably for many years — proving that great performance doesn’t always come from brand-new equipment.

From saving money to supporting sustainability, using a second-hand metal baler truly represents the best of both worlds: economic efficiency and environmental responsibility. Whether you run a small scrap yard or a large recycling plant, this is the machine that helps you recycle smarter and greener.