Introduction

In today’s fast-paced industrial and commercial environments, efficient waste management is crucial for sustainability, cost savings, and regulatory compliance. One of the most effective tools for handling recyclable materials like cardboard, plastics, and textiles is the vertical baler.

Vertical balers compress waste into compact, manageable bales, making storage, transportation, and recycling more efficient. Whether you’re in retail, manufacturing, or waste management, investing in a high-quality vertical baler can significantly improve your operations.

In this comprehensive guide, we’ll explore:

-

What a vertical baler is and how it works

-

Key benefits of using a vertical baler

-

Different types and their applications

-

Factors to consider when choosing one

-

Maintenance and safety best practices

What Is a Vertical Baler?

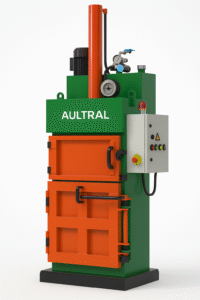

A vertical baler is a machine designed to compress recyclable materials into dense, uniform bales. Unlike horizontal balers, which are typically larger and used for heavy-duty applications, vertical balers are more compact and ideal for businesses with limited space.

How Does a Vertical Baler Work?

-

Loading – Workers feed loose materials (e.g., cardboard, plastic, or foam) into the baler’s chamber.

-

Compression – A hydraulic ram presses the materials downward, compacting them into a tight bale.

-

Tying – Once fully compressed, the bale is secured with wire or strapping.

-

Ejection – The finished bale is ejected from the machine, ready for storage or transport.

Vertical balers are available in various sizes, from small manual models to fully automated systems.

Key Benefits of Using a Vertical Baler

1. Space Efficiency

Vertical balers take up less floor space than horizontal models, making them ideal for warehouses, retail stores, and small recycling centers.

2. Cost Savings

-

Reduced Waste Volume – Compact bales mean fewer pickups and lower disposal costs.

-

Increased Recycling Revenue – Well-compressed bales are easier to sell to recycling facilities.

3. Improved Workplace Safety

By minimizing loose waste, vertical balers reduce tripping hazards and fire risks. Many models also feature safety interlocks to prevent accidents during operation.

4. Environmental Sustainability

By optimizing recycling efforts, businesses can reduce landfill waste and lower their carbon footprint.

5. Versatility

Vertical balers can process a wide range of materials, including:

-

Cardboard & paper

-

Plastic films & bottles

-

Aluminum cans

-

Textiles & foam

Types of Vertical Balers

Different models cater to varying business needs. Here are the most common types:

1. Manual Vertical Balers

-

Operated via a hand lever or foot pedal

-

Best for low to medium waste volumes (e.g., small retail stores)

-

Affordable but requires more labor

2. Semi-Automatic Vertical Balers

-

Hydraulic compression with minimal operator intervention

-

Suitable for medium-volume waste (e.g., supermarkets, distribution centers)

3. Fully Automatic Vertical Balers

-

Programmable with minimal human input

-

Ideal for high-volume operations (e.g., large warehouses, recycling plants)

4. Specialty Vertical Balers

-

Designed for specific materials like PET bottles or foam

-

Often include additional features like pre-crushers

How to Choose the Right Vertical Baler

Selecting the best baler depends on several factors:

1. Waste Volume & Type

-

Estimate daily/weekly waste output.

-

Identify the primary material (cardboard, plastic, etc.).

2. Available Space

Measure the installation area to ensure the baler fits comfortably.

3. Budget

-

Manual balers are cost-effective but require more labor.

-

Automated models have higher upfront costs but save time and labor expenses.

4. Bale Size & Weight Requirements

Check with your recycling provider for preferred bale dimensions.

5. Safety & Compliance Features

Look for OSHA-compliant designs with emergency stop buttons and safety gates.

6. Ease of Maintenance

Choose models with accessible parts and reliable customer support.

Maintenance & Safety Best Practices

To ensure longevity and safe operation:

Maintenance Tips

-

Regularly inspect hydraulic hoses for leaks.

-

Lubricate moving parts as recommended.

-

Keep the baler clean to prevent material buildup.

Safety Guidelines

-

Train all operators on proper usage.

-

Never overload the machine.

-

Always follow lockout/tagout procedures during maintenance.

Conclusion

A vertical baler is an indispensable tool for businesses looking to optimize waste management, reduce costs, and enhance sustainability. By understanding the different types available and selecting the right model for your needs, you can streamline operations and contribute to a greener future.

Ready to invest in a vertical baler? Contact us today for expert recommendations and high-quality machines tailored to your business!

FAQs

Q: How much does a vertical baler cost?

A: Prices range from $3,000 for manual models to $20,000+ for automated systems.

Q: Can a vertical baler handle metal cans?

A: Some heavy-duty models can, but aluminum is more common than steel.

Q: How often should maintenance be performed?

A: Basic checks weekly, with professional servicing annually.

Q: Are vertical balers noisy?

A: Noise levels vary, but most industrial balers operate at 70-80 dB (similar to a vacuum cleaner).

By incorporating a vertical baler into your waste management strategy, you can achieve efficiency, cost savings, and environmental benefits. Upgrade your recycling process today!