In the world of modern waste management and recycling, horizontal balers have become indispensable equipment across industries. Whether you’re dealing with cardboard, plastic film, paper, textile, or even aluminum cans, a horizontal baler offers a streamlined, automated solution for compressing bulky waste into dense, easy-to-transport bales.

In this article, we explore everything you need to know about horizontal balers—from how they work and why they matter, to their key benefits, applications, and how to choose the right one for your business.

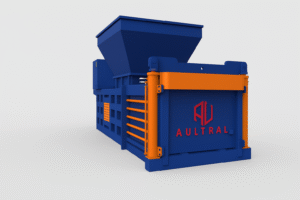

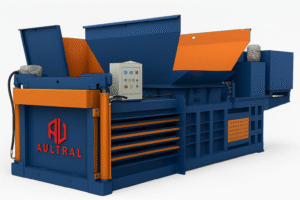

What is a Horizontal Baler?

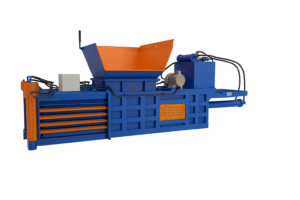

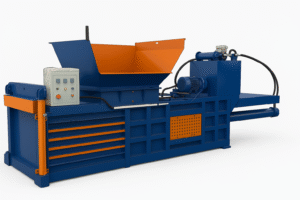

A horizontal baler is a type of industrial machine designed to compress recyclable materials into dense, compact bales for easier storage, transportation, and resale. Unlike vertical balers, where material is loaded from the top, horizontal balers have a larger feed opening and typically load materials from the side or via a conveyor system.

They are ideal for high-volume operations where large quantities of waste are generated daily, such as in factories, logistics centers, supermarkets, printing plants, and recycling stations.

Key Components of a Horizontal Baler

A standard horizontal baler usually consists of the following components:

-

Feed Hopper: Where the waste material enters, either manually or through an automated conveyor.

-

Compression Chamber: The main body where material is pressed into a bale.

-

Hydraulic System: Provides the force necessary to compress the material.

-

Baling Ram: The moving plate that compacts the material.

-

Tying System: Manual or automatic wire tying mechanism to secure the bale.

-

Discharge Door or Channel: Releases the finished bale out of the machine.

Some advanced models also include PLC control systems, touchscreens, sensors, and automatic feeding or tying features.

Types of Horizontal Balers

There are generally two main types of horizontal balers:

1. Semi-Automatic Horizontal Balers

-

Requires manual tying of bales.

-

More affordable and suitable for medium-sized operations.

-

Typically fed manually or by conveyor.

2. Fully Automatic Horizontal Balers

-

Automatically ties the bale after compression.

-

Ideal for large-scale production facilities.

-

Higher cost, but significantly reduces labor time and increases efficiency.

Why Choose a Horizontal Baler?

Here are some of the core benefits of using a horizontal baler:

1. Increased Efficiency

Horizontal balers can process a much higher volume of waste per hour compared to vertical balers. This makes them ideal for businesses with continuous waste output.

2. Labor Cost Reduction

Automated features such as conveyor feeding and automatic tying can drastically reduce the need for manual labor, allowing operators to focus on higher-value tasks.

3. Maximized Space Utilization

By compressing waste into dense bales, horizontal balers free up storage space and reduce clutter in your facility.

4. Environmental Responsibility

Using a baler helps facilitate recycling, contributing to environmental sustainability and improving your corporate image.

5. Improved Safety and Cleanliness

Balers minimize the need for handling loose waste materials, reducing workplace hazards and keeping the environment clean.

Common Applications

Horizontal balers are used in various industries. Some common use cases include:

-

Paper mills: Compacting waste paper and trimmings.

-

Cardboard recyclers: Baling used corrugated boxes (OCC).

-

Supermarkets and retail stores: Managing plastic wrap and boxes.

-

Textile factories: Compressing fabric waste or scraps.

-

Printing houses: Recycling printed paper waste.

-

Recycling centers: Handling mixed recyclables like cans, bottles, or film.

How to Choose the Right Horizontal Baler

When selecting a horizontal baler, consider the following factors:

1. Material Type

Different materials require different compressing power. For example, PET bottles need more pressure than cardboard.

2. Daily Volume Output

Estimate how much waste you process per day. For higher output, a fully automatic baler with higher tonnage is recommended.

3. Available Space

Horizontal balers are large machines. Ensure you have enough floor space, including for material feeding and bale discharge.

4. Automation Level

If you aim to minimize labor involvement, go for a fully automatic model. If your budget is limited and labor is affordable, a semi-automatic baler might suffice.

5. Power Requirements

Check the voltage and motor power specifications to match your factory’s electrical system.

Case Study: Horizontal Baler in a Packaging Factory

A packaging manufacturer producing thousands of cardboard boxes per day faced issues with waste handling and limited space. After installing a fully automatic horizontal baler, they achieved:

-

Reduction in waste storage area by 70%

-

Cut labor time by 50%

-

Earned revenue by selling compacted OCC to recyclers

The return on investment was achieved within 9 months.

Maintenance Tips for Longevity

To ensure your baler operates efficiently for years, follow these maintenance practices:

-

Check hydraulic oil levels regularly

-

Clean sensors and baling chamber weekly

-

Replace worn-out wires and hoses promptly

-

Inspect the ram and cylinder for leaks or damage

-

Lubricate moving parts as per the manual

A well-maintained baler reduces downtime and extends equipment lifespan.

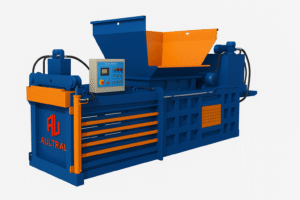

Why Choose Our Horizontal Baler?

Our company offers a wide range of horizontal balers tailored to different materials and business scales. Key features include:

✅ Heavy-duty welded steel structure

✅ High-efficiency hydraulic systems

✅ CE & ISO certified components

✅ Customizable feed hopper and output sizes

✅ Remote control and PLC automation options

✅ Professional technical support & after-sales service

We supply machines to over 60 countries and have gained trust from industries like logistics, recycling, agriculture, and manufacturing.

Final Thoughts

Investing in a horizontal baler is not just about managing waste—it’s about improving operational efficiency, saving labor costs, and committing to a more sustainable future. If you’re ready to optimize your recycling processes and reduce clutter in your workspace, a horizontal baler is the tool you need.

Looking for the right horizontal baler for your business?

Contact us today for a free consultation and quote. Let us help you choose the perfect solution based on your needs.