Meta Description: Discover whether horizontal or vertical balers are better for compressing solid metal and plastic waste. Learn the key differences, advantages, and recommendations for efficient recycling.

Introduction

As industries strive for higher recycling efficiency and waste management optimization, the choice of baling equipment plays a crucial role. Solid metal and plastic wastes are two common yet challenging materials to process due to their volume, density, and handling requirements. One of the most frequent questions buyers ask is:

Should I choose a horizontal baler or a vertical baler for metal and plastic waste?

In this blog, we explore the characteristics of both types of balers and recommend the best option based on your material type and production needs.

What Are Vertical and Horizontal Balers?

-

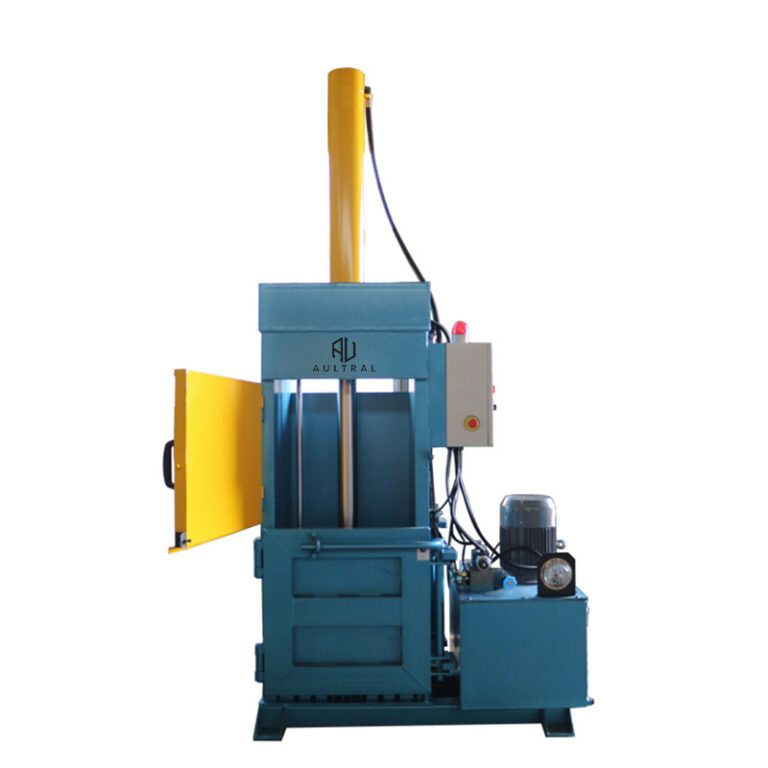

Vertical Balers:

Vertical balers compress materials using a downward hydraulic ram. Operators load the waste from the front, and bales are usually tied manually. These machines have a small footprint, are cost-effective, and are ideal for lower-volume operations. -

Horizontal Balers:

Horizontal balers compress materials sideways and can be manually or automatically fed (e.g., by conveyor). These machines can be semi-automatic or fully automatic, and they are ideal for high-volume operations.

Solid Plastic Waste: Vertical or Horizontal Baler?

Material Characteristics:

Plastic waste (such as bottles, containers, packaging film) is lightweight but bulky, and it often requires high compaction force to reduce volume.

Best Option:

✅ Horizontal Baler

-

Ideal for large-scale plastic waste recycling facilities

-

Supports automatic feeding and continuous operation

-

Produces uniform, dense bales (good for transportation and resale)

-

Higher efficiency and time-saving for bulk processing

❕ Vertical Baler is suitable for:

-

Small to medium businesses with limited plastic waste

-

Manual operation with lower initial investment

-

Businesses with space constraints

Conclusion for Plastics:

If your daily plastic waste output is moderate to high, a horizontal baler provides better productivity and long-term savings.

Solid Metal Waste: Vertical or Horizontal Baler?

Material Characteristics:

Metal waste (such as aluminum cans, light scrap, or stainless steel offcuts) is dense, often sharp, and can be heavy even in small volumes.

Best Option:

✅ Horizontal Baler (Heavy-duty or customized metal baler)

-

Capable of handling dense and abrasive materials

-

Equipped with stronger hydraulic systems

-

Can integrate with scrap processing lines for continuous feeding

-

Produces compact, transport-friendly bales

❕ Vertical Baler can be used for:

-

Low-volume, light-duty metal scrap

-

Manual loading of items like aluminum cans or tins

-

Facilities with limited floor space or budget

Special Note: For heavy or irregular metal scrap (e.g., rods, pipes), metal balers with shear or lid-style compression (not traditional vertical balers) are more suitable.

Key Comparison Table

| Feature | Vertical Baler | Horizontal Baler |

|---|---|---|

| Footprint | Compact | Larger space required |

| Operation | Manual | Semi-/Fully automatic |

| Output Volume | Low to medium | Medium to high |

| Baling Time | Slower | Faster (continuous) |

| Cost | Lower | Higher initial investment |

| Suitable for Plastic? | Yes (low volume) | Yes (high volume) |

| Suitable for Metal? | Yes (light) | Yes (dense/heavy) |

Final Recommendation

Choosing between a vertical and horizontal baler depends on the type of waste, processing volume, and available space.

-

For solid plastic waste, horizontal balers offer the best efficiency for medium to high volumes.

-

For solid metal waste, horizontal balers—especially those designed for metal—deliver stronger compression and safer operation.

For small businesses or startups, vertical balers can be a good entry-level solution. But as operations scale, horizontal balers offer superior long-term benefits.