In today’s rapidly evolving industrial and environmental landscape, waste management has become more than just a legal requirement—it’s now a business opportunity and a moral obligation. Whether you’re in manufacturing, logistics, agriculture, or retail, managing waste efficiently can save costs, improve safety, and build a greener reputation.

One of the most powerful yet underappreciated tools in this domain is the baler machine. In this article, we will explore what a baler machine is, how it works, the different types available, and most importantly, why your business needs one—today.

🔍 What Is a Baler Machine?

A baler machine is a piece of equipment used to compress materials into compact bales for easier handling, storage, and transport. Commonly used in recycling and waste management, balers reduce the volume of recyclable waste like cardboard, paper, plastic, and even metal.

They’re called “balers” because they create bales—neat, dense blocks of material that can be stacked or sold to recycling companies.

🏭 How Does a Baler Work?

Though designs vary, the typical baler machine follows this process:

-

Loading: Waste material (e.g., cardboard boxes) is loaded into the chamber.

-

Compression: A hydraulic ram presses the material into a dense form.

-

Tying/Wrapping: The compressed bale is tied with wire or strapping.

-

Ejection: The finished bale is ejected and ready for storage or transport.

This simple yet powerful process can reduce material volume by up to 90%, depending on the type of waste and baler used.

📦 Types of Baler Machines

Different industries require different baler solutions. Below are the most common types:

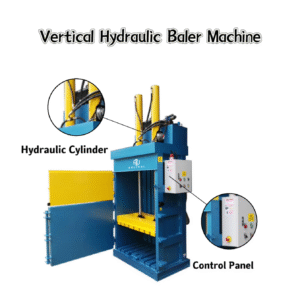

1. Vertical Balers

-

Ideal for small to medium-scale operations.

-

Space-saving design.

-

Manual loading and unloading.

-

Best for cardboard, plastic, and paper.

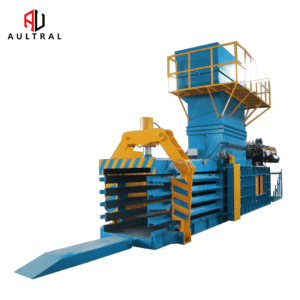

2. Horizontal Balers

-

Designed for high-volume processing.

-

Can be semi-automatic or fully automatic.

-

Often equipped with conveyors for continuous feeding.

-

Suitable for large warehouses, recycling plants, and distribution centers.

3. Manual-Tie Balers

-

Operators tie the bale manually.

-

Lower cost, but requires more labor.

4. Auto-Tie Balers

-

Automatically ties bales with wire or strapping.

-

Great for operations with minimal staff.

5. Specialty Balers

-

Foam balers, textile balers, metal balers, and more.

-

Customized to specific materials and industries.

💡 7 Reasons Your Business Should Invest in a Baler

If you’re still on the fence, here are 7 compelling reasons why investing in a baler machine is a smart move:

1. Save on Waste Disposal Costs

By reducing the volume of waste, you’ll make fewer trips to disposal sites or pay less for waste hauling services.

2. Increase Recycling Revenue

Tightly packed bales are more valuable to recyclers. You may even turn your waste into a profit center.

3. Improve Workplace Safety and Cleanliness

Loose cardboard and plastic can clutter your workspace, creating hazards. A baler helps keep things neat and reduces fire risk.

4. Save Valuable Floor Space

Bulky waste eats up space that could be used for inventory or production. A baler helps you reclaim your work area.

5. Enhance Corporate Sustainability

Using a baler shows that your business takes environmental responsibility seriously—a powerful message for customers and partners.

6. Automate Waste Management

With auto-tie balers and conveyors, waste processing becomes efficient and almost hands-free.

7. Qualify for Green Certifications

Baling and recycling waste can help you meet ISO 14001 or LEED certification requirements.

🏢 Who Uses Baler Machines?

Balers aren’t just for recycling centers. Many industries benefit from using them:

-

Retail Chains: Manage packaging waste from daily deliveries.

-

Supermarkets: Baling plastic wrap and cardboard boxes.

-

Logistics Companies: Keep packaging areas clean and efficient.

-

Manufacturers: Compress scrap materials like foam, metal, or textiles.

-

Agriculture: Compact crop residue or hay.

Even office buildings and hotels can benefit from small vertical balers to handle their waste responsibly.

📊 Choosing the Right Baler Machine for Your Needs

Before buying a baler, ask yourself:

-

What material will I be baling?

-

How much volume do I process daily?

-

How much floor space can I dedicate?

-

Do I want manual or automatic operation?

-

What is my budget?

A trusted baler supplier will help you assess your needs and recommend a tailored solution.

🛠️ Maintenance and Safety Tips

A baler is a mechanical machine and requires regular care:

-

Inspect hydraulics and oil levels regularly.

-

Keep the chamber clean.

-

Replace worn parts promptly.

-

Train staff on safe operation and emergency stops.

With good maintenance, your baler can last 10+ years with consistent performance.

🌍 Final Thoughts: A Small Machine with Big Impact

While balers may not be as flashy as new tech gadgets or heavy-duty crushers, they quietly revolutionize how companies handle waste. In an era where sustainability equals profitability, a baler machine is more than just equipment—it’s a strategic investment.

From improving logistics to contributing to a greener planet, the benefits of baler machines go far beyond waste compression.

If your business is still tossing loose cardboard into bins or paying hefty fees for waste pickup, it’s time to rethink your approach.

👉 Choose a baler. Save money. Save space. Save the Earth.

Would you like me to format this for your website, add keywords for SEO, or adapt it to a more casual or technical tone?