In the modern recycling industry, efficiency, durability, and cost-effectiveness are essential. A horizontal metal baler plays a vital role in compressing scrap metal into dense, manageable bales that are easier to store, transport, and melt. For many recycling plants and metal processing yards, choosing a used horizontal metal baler is a smart and economical investment — offering strong performance at a lower cost without compromising quality.

What Is a Horizontal Metal Baler?

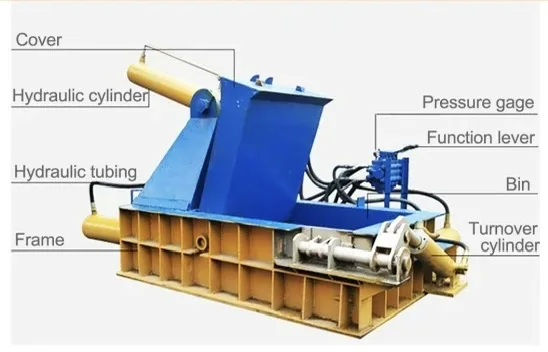

A horizontal metal baler is a hydraulic machine designed to compress scrap metal materials, such as steel, aluminum, copper, or iron, into compact bales. The horizontal design allows continuous feeding and high-volume processing, making it ideal for large recycling centers and metal recovery facilities.

Compared with vertical balers, horizontal balers are built for heavy-duty operations, supporting automatic feeding, hydraulic compression, and efficient bale ejection. These machines are suitable for processing various scrap types, including metal sheets, cuttings, cans, and small structural parts.

Application of Horizontal Metal Baler in Scrap Recycling

The recycling industry relies on baling machines to streamline the handling and logistics of scrap materials. Here’s how a horizontal metal baler like model Y81Q-1350 contributes to this process:

-

Volume Reduction:

Loose metal occupies large spaces and is difficult to transport. The baler compresses the scrap into uniform bales, reducing storage and shipping costs. -

Efficient Handling:

Compact bales can be easily stacked, loaded, and transported to melting plants, improving overall logistics efficiency. -

Increased Recycling Value:

Well-compressed bales reduce oxidation and contamination, preserving material quality and increasing resale value. -

Environmental Benefits:

Recycling compacted scrap reduces landfill waste and supports a sustainable circular economy. -

Safety and Cleanliness:

Baling reduces scattered scrap and sharp edges, keeping the recycling yard cleaner and safer for workers.

Model Y81Q-1350 – Reliable Performance for Scrap Baling

The Y81Q-1350 Horizontal Metal Baler is one of the reliable models for small to medium-scale recycling operations. It features strong hydraulic power, compact design, and easy maintenance.

Main Specifications:

-

Model: Y81Q-1350

-

Max Cylinder Force: 135 Ton

-

Press Box Size: 1400 × 600 × 600 mm

-

Bale Size: 600 × 240 mm

-

Bale Weight: 50–75 kg

-

Power: 22 kW

With a 135-ton hydraulic system, this baler delivers high compression force suitable for processing various non-ferrous and ferrous metals. The press box of 1400×600×600 mm provides enough space for continuous feeding, while the bale size of 600×240 mm ensures compact output that is easy to handle.

Its 22 kW motor guarantees stable power performance while maintaining energy efficiency — a crucial factor for recycling operations aiming to reduce operational costs.

Advantages of Buying a Used Horizontal Metal Baler

Purchasing a used metal baler is becoming increasingly popular among recycling facilities, especially for those expanding operations or working with limited budgets. Here are some key benefits:

-

Cost-Effective Investment:

A used horizontal baler offers significant cost savings — often 30–60% cheaper than a new one — allowing businesses to invest funds in other production equipment or logistics. -

Proven Reliability:

Quality used machines, when properly maintained, still provide excellent performance. Models like Y81Q-1350 are built with durable hydraulic systems and heavy steel structures that ensure long-term use. -

Faster ROI:

Lower purchase costs mean a shorter payback period. Companies can start generating returns from recycling operations more quickly. -

Environmentally Friendly Choice:

Buying used equipment supports resource reuse, aligning with the sustainability principles that recycling businesses already promote. -

Available Upgrades:

Many suppliers refurbish used balers with new hydraulic seals, motors, or control systems, improving performance while keeping costs low.

How to Choose the Right Used Horizontal Metal Baler

When purchasing a used horizontal metal baler, it’s important to consider the following factors:

-

Compression Force: Ensure the machine’s hydraulic power meets your processing requirements. For example, the 135T pressure of the Y81Q-1350 is suitable for medium-scale scrap yards.

-

Bale Density and Size: Choose a machine that produces bale sizes compatible with your transport and smelting processes.

-

Hydraulic System Condition: Check for leaks, smooth cylinder movement, and consistent pressure output.

-

Control System: Opt for simple yet reliable electrical and hydraulic controls to ensure easy operation and maintenance.

-

After-Sales Support: Buy from reputable suppliers who can provide technical support, spare parts, and installation guidance.

Why Choose a Used Y81Q-1350 from a Reliable Manufacturer

A reputable manufacturer like Shanghai Aultral Machinery Co., Ltd. ensures that even second-hand machines meet strict performance standards. All used Y81Q-1350 units are inspected, refurbished if necessary, and tested before delivery to ensure safety and efficiency.

This guarantees that you receive a cost-effective yet dependable baling solution that can continuously handle large volumes of scrap with minimal downtime.

The used horizontal metal baler is a perfect solution for scrap metal recyclers who value performance and affordability. Machines like the Y81Q-1350, with 135T cylinder force and 22 kW power, deliver reliable compression, consistent bale sizes, and long-term durability — making them an excellent choice for businesses seeking to optimize recycling operations.