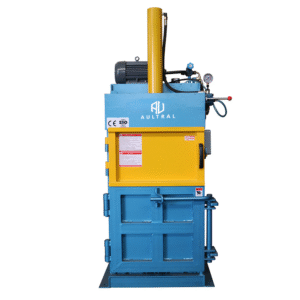

In an era where sustainability and operational efficiency are critical, businesses across industries are constantly seeking smarter solutions to handle waste. One such indispensable tool is the Vertical Baling Press Machine. Compact, cost-effective, and efficient, this type of baler plays a vital role in recycling and waste volume reduction, particularly in settings where floor space is limited.

What Is a Vertical Baling Press Machine?

A vertical baling press machine is a mechanical device used to compress and bale recyclable materials such as cardboard, paper, plastic, and textile waste. Unlike horizontal balers, vertical balers compress material from top to bottom. These machines are particularly popular in retail stores, warehouses, small recycling operations, and manufacturing facilities where space is a premium.

How Does It Work?

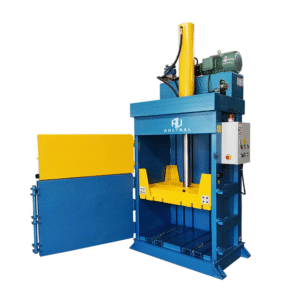

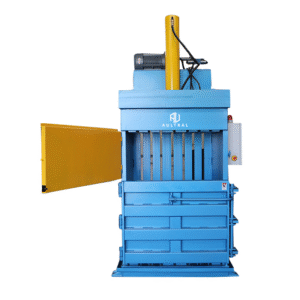

The working principle of a vertical baler is straightforward:

- Waste material is loaded into the baler chamber from the front.

- The pressing plate (ram) moves down vertically and compresses the waste.

- Once the material is compacted, the baler ties the bale with wires or strapping material.

- The bale is then manually ejected or removed using a bale trolley or hydraulic ejector (depending on the model).

Key Features of Vertical Baling Press Machines

- Space-Saving Design: Ideal for facilities with limited floor space.

- User-Friendly Operation: Simple control panels and easy bale removal.

- Versatility: Can handle various recyclable materials.

- Affordable Cost: Lower initial investment compared to horizontal balers.

- High Compression Force: Capable of producing dense bales.

- Manual or Semi-Automatic Options: Suitable for different production volumes.

Common Applications

Vertical balers are used in a variety of industries, including:

- Retail and Supermarkets: For managing cardboard boxes and plastic packaging waste.

- Warehouses: For compacting packaging materials and plastic wrap.

- Textile Industry: For baling fabric scraps and clothes.

- Printing and Paper Companies: For disposing of waste paper efficiently.

- Restaurants and Hotels: For reducing the volume of food packaging waste.

Advantages of Using Vertical Balers

1. Cost Savings

By compacting waste into bales, businesses reduce the frequency of waste pickups and lower transportation costs. This can result in substantial savings over time.

2. Improved Recycling Rates

Sorted and baled materials are easier to recycle. Vertical balers help businesses manage waste streams more effectively, contributing to environmental sustainability.

3. Cleaner Workspaces

Balers help in maintaining a clean and safe workplace by keeping loose waste under control.

4. Regulatory Compliance

Proper waste management supports compliance with environmental regulations and helps avoid penalties.

5. Revenue Generation

Recyclable bales can be sold to recycling companies, providing an additional income stream.

Choosing the Right Vertical Baler for Your Business

When selecting a vertical baler, consider the following factors:

- Type and Volume of Waste: Identify the most common types of waste you generate.

- Available Space: Ensure the baler fits comfortably within your working area.

- Bale Size and Weight Requirements: Choose a baler that produces bales of suitable dimensions and density.

- Manual vs. Semi-Automatic: Depending on your labor resources and output.

- Power Supply: Check compatibility with your facility’s power system (single-phase or three-phase).

Popular Models and Specifications

While specific models may vary, here are some typical specifications you might find in vertical balers:

- Bale Size: 600x400x600mm to 1200x800x1000mm

- Pressing Force: 10 to 60 tons

- Cycle Time: 20 to 60 seconds

- Power: 5.5kW to 15kW

- Weight: 800kg to 2500kg

Maintenance and Safety Tips

- Regular Inspection: Check hydraulic systems and seals for leaks.

- Keep Clean: Clear debris from around the machine to avoid operational issues.

- Follow Manufacturer’s Guidelines: Adhere to safety and maintenance instructions.

- Train Operators: Ensure staff are well-trained to handle the machine safely.

Final Thoughts

The vertical baling press machine is a practical and efficient waste management solution for small to medium-sized businesses. Its space-saving design, cost-effectiveness, and ability to generate recycling revenue make it an essential part of modern industrial and commercial operations.

Whether you’re running a retail outlet, managing a warehouse, or overseeing production in a factory, investing in a vertical baler is a step toward smarter, greener, and more economical operations.

If you are ready to explore vertical baler options, feel free to contact us — our professional team is here to help you select the perfect model for your needs!