In today’s fast-paced recycling and waste management industries, efficiency is everything. Companies are constantly looking for ways to reduce storage space, lower transportation costs, and make waste handling more environmentally friendly. This is where the hydraulic baling press machine—often simply called a hydraulic baler—comes into play.

If you’re new to this type of machine or considering investing in one for your business, this comprehensive guide will give you all the answers. We’ll cover what a hydraulic baling press is, why it is important, and how to choose and use it effectively.

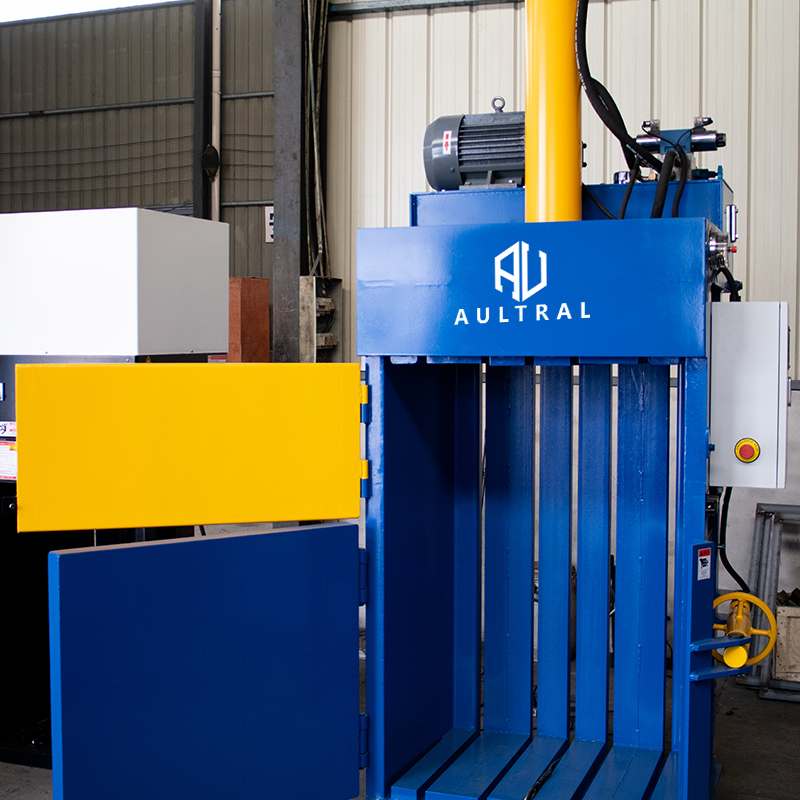

What is a Hydraulic Baling Press Machine?

A hydraulic baling press machine is an industrial device that compresses loose and bulky materials into compact, easy-to-handle bales. These machines use hydraulic pressure to apply force, squeezing materials such as waste paper, cardboard, plastic, textile scraps, and even scrap metal into tightly bound blocks.

Unlike manual or mechanical balers, hydraulic balers provide much higher compaction force, allowing them to process tougher materials like aluminum cans, steel scraps, or PET bottles.

Key Components of a Hydraulic Baling Press

Hydraulic Cylinder – Provides the pressing force.

Pressing Chamber – Where loose materials are placed for compression.

Control System – Operates the machine with simple levers or PLC controls.

Bale Ejector – Automatically pushes out the finished bale.

Binding System – Uses wires, straps, or ropes to keep bales compact.

Common Types of Hydraulic Balers

Vertical Baler – Compact design, ideal for small to medium businesses.

Horizontal Baler – Handles higher volumes, suitable for large recycling centers.

Fully Automatic Baler – Continuous feeding and baling, perfect for high-output operations.

Metal Baler / Scrap Baling Press – Specially designed for compressing heavy and rigid metal scrap.

In short, a hydraulic baling press machine is like a giant hand that squeezes waste into neat, dense packages for easier handling, storage, and transport.

Why Should You Use a Hydraulic Baling Press?

Now that we understand what a hydraulic baling press is, let’s explore why businesses across industries—from supermarkets to recycling plants—invest in these machines.

- Space Optimization

Loose waste takes up enormous amounts of storage space. A hydraulic baler can reduce the volume of materials by up to 80–90%, freeing up valuable warehouse or factory floor space.

- Lower Transportation Costs

Compact bales mean more materials can fit into a single truckload, cutting down on transportation frequency and costs.

- Higher Recycling Value

Recycling companies prefer densely packed, uniform bales because they are easier to handle, sort, and process. This often translates into higher resale value for your waste materials.

- Improved Workplace Safety & Cleanliness

By keeping waste neatly baled and tied, workplaces remain safer, cleaner, and more organized. This reduces fire hazards and improves employee efficiency.

- Environmental Benefits

Hydraulic baling press machines play a crucial role in sustainable waste management by ensuring recyclable materials don’t end up in landfills. They also support circular economy practices.

- Versatility Across Industries

Whether you’re in printing, packaging, textiles, logistics, supermarkets, or scrap metal recycling, there’s a hydraulic baler designed for your needs.

How to Choose and Use a Hydraulic Baling Press

If you are planning to buy a hydraulic baler, you must consider your materials, output needs, and budget. Here’s a detailed breakdown:

Step 1: Identify Your Materials

Lightweight materials (cardboard, paper, PET bottles) → Vertical or small horizontal baler.

Heavy-duty materials (scrap metal, aluminum, copper wire) → Scrap metal hydraulic baler.

Mixed waste → A multi-purpose horizontal or fully automatic baler.

Step 2: Estimate Your Daily Output

Ask yourself: How much waste do I generate per day?

Low output (1–3 tons/day) → A vertical baler is enough.

Medium output (5–10 tons/day) → Horizontal semi-automatic baler.

High output (10+ tons/day) → Fully automatic hydraulic baling press.

Step 3: Consider Space and Power Requirements

Vertical balers are compact and suitable for smaller workshops.

Horizontal and automatic balers require larger installation space and higher power capacity.

Step 4: Look for Essential Features

Bale size adjustability

Automatic tying system

Energy-efficient motor

Reliable hydraulic pump and cylinders

Safety interlocks and emergency stop functions

Step 5: Evaluate the Supplier

Choose a trusted manufacturer with CE certification, after-sales service, spare parts availability, and proven customer feedback.

Tips for Operating and Maintaining a Hydraulic Baling Press

To ensure long-term performance, follow these practical tips:

Regular Inspection – Check hydraulic oil, seals, and hoses for leaks.

Clean the Chamber – Avoid material buildup that reduces compaction efficiency.

Use the Right Binding Materials – Ensure wires or straps are strong enough.

Train Operators – Safety comes first; only trained staff should run the machine.

Schedule Preventive Maintenance – Replace worn-out parts before breakdowns occur.

Frequently Asked Questions (FAQ) About Hydraulic Baling Press Machines

- What materials can a hydraulic baling press handle?

A hydraulic baler is highly versatile. It can process a wide range of materials including waste paper, corrugated cardboard, PET bottles, textile waste, foam, aluminum cans, copper wires, and heavy scrap metal. Depending on the machine type, it can handle both light packaging waste and tough industrial scraps

- How much does a hydraulic baling press cost?

The cost varies depending on the size, type, and automation level of the machine.

Vertical balers: More affordable, typically suitable for small businesses.

Horizontal balers: Medium price range, designed for higher volumes.

Fully automatic balers: Higher investment, but they save a lot of labor costs.

Scrap metal balers: Prices vary widely depending on tonnage and configuration.

It’s always important to consider long-term ROI—a good baler pays for itself through reduced transportation, increased recycling value, and labor savings.

- How much space do I need for a hydraulic baling press?

Vertical balers are compact and can be installed in small warehouses or retail backrooms. Horizontal and automatic balers require more floor space and may need special installation planning. Always consult with your supplier to design the best layout for your facility.

- Is it difficult to operate a hydraulic baling press?

Not at all. Most modern balers come with user-friendly controls and require minimal training. With safety interlocks, emergency stop buttons, and clear indicators, operators can run the machine confidently. Training usually takes only a few hours.

- How do I maintain my hydraulic baling press for long-term use?

Regularly check hydraulic oil levels and replace them as recommended.

Inspect cylinders, hoses, and seals for leakage.

Clean the pressing chamber frequently to avoid material buildup.

Replace binding wires or straps on time.

Have a scheduled maintenance plan with your supplier.

- What industries benefit the most from hydraulic baling presses?

Hydraulic balers are widely used in:

Recycling centers (paper, plastic, metals)

Manufacturing plants (handling production waste)

Textile and garment factories (fabric waste management)

Supermarkets and logistics centers (cardboard packaging waste)

Scrap metal yards (compressing heavy ferrous and non-ferrous materials)

- Are hydraulic baling press machines eco-friendly?

Yes! By reducing waste volume and making recycling more efficient, hydraulic balers help companies lower their carbon footprint, cut landfill contributions, and promote circular economy practices.

Final Thoughts

Investing in a hydraulic baling press machine is not just about handling waste—it’s about improving efficiency, saving money, and supporting sustainability. With the right machine, your business can enjoy long-term cost reductions, better workplace organization, and a positive impact on the environment.

At Aultral, we specialize in providing reliable hydraulic balers tailored to your exact needs. Whether you’re handling lightweight packaging waste or heavy-duty scrap metal, we have the right solution for you.