Introduction to Shearing Machines

Shearing machines, commonly referred to as shearers or power shears, represent one of the most fundamental yet vital pieces of equipment in metal fabrication and various industrial applications. These machines perform the essential function of cutting sheet metal and other materials by applying a tremendous shearing force between two blades. Unlike sawing or other cutting methods that remove material, shearing produces clean cuts by forcing the material beyond its yield strength, causing it to fracture along the line of the blades.

The history of shearing machines dates back to the early Industrial Revolution when manual shears were first mechanized to increase productivity in metalworking shops. Today’s industrial shearing machines have evolved into sophisticated, computer-controlled systems capable of handling materials of varying thicknesses with remarkable precision. From small bench-mounted units to massive hydraulic guillotine shears capable of processing steel plates several inches thick, these machines have become indispensable in manufacturing, construction, automotive, aerospace, and countless other industries.

Types of Shearing Machines

Modern industry utilizes several distinct types of shearing machines, each designed for specific applications and material requirements. Understanding these variations is crucial for selecting the appropriate equipment for a given manufacturing need.

Mechanical Shears represent the most common type, using a motor-driven flywheel to store and release energy for the cutting action. These machines offer high-speed operation and are particularly effective for high-volume production environments where speed and repeatability are paramount. The mechanical advantage provided by the flywheel allows for consistent cutting force throughout the stroke, making them ideal for processing thinner gauge materials.

Hydraulic Shears have gained significant popularity in recent decades due to their ability to maintain constant cutting force regardless of material thickness. These machines use hydraulic cylinders to power the ram, providing several advantages including adjustable stroke length, overload protection, and the capability to cut thicker materials. Hydraulic systems can maintain full tonnage throughout the entire cutting stroke, unlike mechanical systems where force varies with the position of the ram.

Pneumatic Shears serve as a lighter alternative, using compressed air to generate cutting force. While they lack the power of hydraulic or mechanical systems, pneumatic shears excel in applications requiring portability or where electrical or hydraulic power isn’t readily available. They’re commonly found in maintenance shops and field operations rather than high-volume production environments.

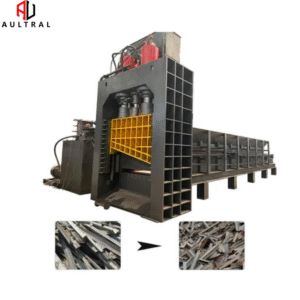

Alligator Shears, named for their hinged jaw design resembling an alligator’s mouth, specialize in cutting scrap metal, bars, and other long stock. These heavy-duty machines typically feature a hydraulic-powered lower jaw that closes against a stationary upper jaw, making them ideal for recycling operations and foundries.

Bench Shears provide compact solutions for small shops and light-duty applications. These manually operated or power-assisted machines mount to workbenches and handle light-gauge materials, offering precision for detailed work or low-volume production.

Key Components and Working Principles

Understanding the fundamental components and operational principles of shearing machines reveals why they remain so effective for industrial cutting applications.

The frame serves as the machine’s backbone, constructed from heavy-duty steel to withstand the tremendous forces generated during operation. Modern frames often utilize box-type designs for maximum rigidity and minimal deflection during cutting. The frame must maintain perfect alignment between all moving components to ensure cutting accuracy throughout the machine’s service life.

Blades represent the heart of any shearing machine, with upper and lower blades working in opposition to create the cutting action. Blade materials typically include high-carbon steel, tool steel, or tungsten carbide, chosen based on the materials being processed and production requirements. Proper blade clearance—the gap between upper and lower blades—is critical for achieving clean cuts and maximizing blade life. This clearance varies depending on material type and thickness, generally ranging from 5% to 10% of material thickness.

The hold-down mechanism plays a crucial role in material positioning and cut quality. This component clamps the workpiece firmly against the machine table during cutting, preventing material movement that could lead to distorted edges or safety hazards. Modern machines often feature adjustable or programmable hold-down pressure to accommodate different material types and thicknesses.

Backgauges on precision shearing machines provide accurate material positioning for repetitive cuts. These computer-controlled measuring systems can store multiple programs for different part dimensions, significantly enhancing productivity in job shop environments. Advanced backgauges may incorporate automatic adjustment between cuts and integration with factory information systems.

The shearing process itself relies on basic physics principles. As the upper blade descends, it deforms the material until reaching the yield point where fracture occurs. The quality of the cut edge depends on several factors including blade sharpness, proper clearance, material properties, and cutting speed. A properly executed shear leaves a clean fracture with minimal deformation, while improper setup can result in excessive burring, edge rolling, or secondary deformation.

Technological Advancements in Shearing Equipment

The shearing machine industry has witnessed remarkable technological progress in recent decades, transforming these fundamental tools into highly sophisticated production systems.

CNC (Computer Numerical Control) technology has revolutionized shearing machine operation, enabling unprecedented precision and repeatability. Modern CNC shears can store hundreds of cutting programs, automatically adjust blade gaps and backgauges, and integrate with factory networks for seamless production flow. Touchscreen interfaces allow operators to input cutting parameters easily, while advanced control systems monitor machine performance and predict maintenance needs.

Servo-electric drives are increasingly replacing traditional hydraulic systems in some applications, offering energy savings, reduced noise, and lower maintenance requirements. These systems use high-torque electric motors coupled with precision ball screws to deliver the required cutting force while maintaining exact control over ram position and speed throughout the cutting cycle.

Laser measurement systems have been incorporated into high-end shearing machines to verify material positioning before cutting and inspect cut quality afterward. These systems can automatically compensate for variables like material springback or thermal expansion, ensuring consistent results even under changing environmental conditions.

Smart blade technology represents another frontier in shearing machine development. Some advanced systems now incorporate sensors within the blades to monitor cutting forces in real-time, detecting dull blades or incorrect clearances before they affect product quality. Other innovations include quick-change blade systems that minimize downtime during blade replacement or rotation.

Energy recovery systems in hydraulic shears capture and reuse energy during the non-cutting portions of the operating cycle, significantly reducing power consumption. These systems are particularly valuable in high-production environments where energy costs represent a substantial portion of operating expenses.

Industrial Applications of Shearing Machines

The versatility of shearing machines ensures their presence across a broad spectrum of industries, each with unique requirements and challenges.

In the automotive industry, shearing machines process everything from thin aluminum body panels to high-strength steel chassis components. The ability to quickly change between different material types and thicknesses makes modern shears invaluable in this fast-paced manufacturing environment. Automotive suppliers particularly value machines with automatic thickness detection that can adjust cutting parameters without operator intervention.

Aerospace manufacturers demand exceptionally high precision when cutting aluminum, titanium, and composite materials for aircraft components. Specialized shearing machines for this sector often feature enhanced vibration damping, micro-adjustment capabilities, and clean-room compatible designs to meet stringent industry standards.

The construction industry relies on heavy-duty shearing machines to process structural steel components. Large-capacity hydraulic shears cut steel plates, beams, and rebar to precise lengths for building frameworks, bridges, and infrastructure projects. Many construction-oriented shears incorporate features like angle cutting capabilities for creating complex structural shapes.

Appliance manufacturers use precision shears to produce consistent, burr-free edges on sheet metal for refrigerators, ovens, and other household products. The electronics industry employs delicate bench shears for cutting chassis components and shielding materials where precision outweighs production speed requirements.

In metal service centers, shearing machines serve as primary processing equipment, cutting large coils and sheets into smaller, customer-specific sizes. These high-volume operations often utilize tandem shear lines with automatic material handling systems that can process thousands of cuts per day with minimal operator involvement.

The recycling industry has developed specialized shearing machines capable of processing scrap metal of varying sizes and compositions. Heavy-duty alligator shears and guillotine shears reduce large scrap items into manageable pieces for melting and reprocessing. Some recycling shears incorporate pre-compaction systems to increase material density before cutting, improving overall processing efficiency.

Safety Considerations and Best Practices

Given the tremendous forces involved, operating shearing machines requires strict adherence to safety protocols to prevent serious injuries.

Machine guarding represents the first line of defense, with physical barriers preventing access to the cutting area during operation. Modern shears often incorporate light curtains or laser scanners that automatically stop the machine if any obstruction is detected in the danger zone. Two-hand control systems require operators to use both hands to initiate a cutting cycle, keeping them clear of the blades.

Regular maintenance is essential for safe operation. This includes periodic inspection and replacement of blades, verification of hydraulic system integrity, and checking all safety interlocks. Proper lubrication of moving parts reduces wear while preventing overheating that could lead to component failure.

Operator training should encompass not only machine operation but also material handling techniques and emergency procedures. Even with advanced safety systems, proper training remains the most effective accident prevention measure. Training programs should emphasize the importance of never reaching into the shear area while the machine is operational, even during jams or misfeeds.

Ergonomic design in modern shearing machines reduces fatigue and repetitive stress injuries among operators. Features like height-adjustable tables, anti-fatigue matting, and power-assisted material handling systems contribute to both safety and productivity in high-volume environments.

Noise control measures have become increasingly important as workplace safety regulations tighten. Many newer shearing machines incorporate sound-dampening enclosures, vibration isolation mounts, and noise-reducing blade designs to protect operators’ hearing in industrial environments.

Future Trends in Shearing Technology

As manufacturing evolves, shearing machine technology continues advancing to meet new challenges and opportunities.

Industry 4.0 integration is transforming shearing machines into connected components of smart factories. Modern systems can transmit real-time performance data to plant management systems, enabling predictive maintenance and optimal production scheduling. Some advanced machines now feature remote monitoring capabilities, allowing technicians to diagnose issues and even perform adjustments from off-site locations.

Additive manufacturing techniques are being applied to shear blade production, creating complex internal cooling channels and customized edge geometries that extend blade life and improve cut quality. These techniques allow for blade designs that would be impossible with traditional manufacturing methods.

Artificial intelligence applications are beginning to emerge in shearing operations. Machine learning algorithms can analyze cutting force data to detect subtle changes in material properties or blade condition, automatically adjusting machine parameters to maintain optimal performance. Some systems can even predict blade failure before it occurs, scheduling replacements during planned downtime.

Sustainable design principles are influencing new shear development, with manufacturers focusing on energy efficiency, reduced lubricant consumption, and recyclability of components. Water-based hydraulic fluids and biodegradable lubricants are becoming more common as environmental regulations tighten worldwide.

Hybrid machine concepts that combine shearing with other processes are gaining traction. Examples include shear-press combos that can both cut and form parts in a single setup, reducing material handling and improving overall efficiency. Other systems integrate shearing with laser or plasma cutting for applications requiring both straight cuts and complex contours.

Conclusion

From their humble beginnings as simple metal-cutting devices, shearing machines have evolved into sophisticated production systems that form the backbone of modern manufacturing. Their ability to deliver precise, repeatable cuts at high speeds makes them indispensable across countless industries. As technology advances, these machines continue to incorporate smarter controls, improved safety features, and greater connectivity, ensuring their relevance in the factories of tomorrow.

The future of shearing technology promises even greater integration with digital manufacturing systems, enhanced material handling capabilities, and continued improvements in energy efficiency. While newer cutting technologies like lasers and waterjets have found their niches, the fundamental efficiency and simplicity of mechanical shearing ensure these machines will remain essential tools for metal fabrication and processing well into the foreseeable future.

For manufacturers seeking to maintain competitive edges in their operations, investing in modern shearing technology—whether as standalone machines or as part of integrated production lines—represents a proven path to improved productivity, reduced waste, and higher quality output. As materials science advances and new alloys emerge, shearing machine manufacturers will continue adapting their designs to meet these fresh challenges, maintaining the shear’s position as one of industry’s most vital and versatile tools.