Introduction

With the rapid evolution of electronic products, electronic waste (e-waste) has become one of the fastest-growing waste streams globally. According to United Nations data, global e-waste exceeded 57.4 million tons in 2023, yet only 17.4% was properly recycled. E-waste contains valuable metals (such as gold, silver, and copper) as well as hazardous substances (like lead and mercury), making efficient and environmentally friendly processing a critical challenge.

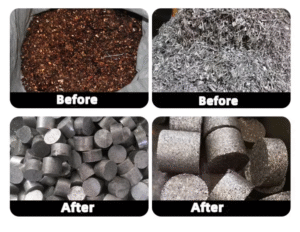

In the e-waste recycling process, shredders and shears play a vital role. Shredders break down complex components like circuit boards and hard drives for metal recovery, while shears dismantle metal casings and frames to improve overall recycling efficiency.

The Growing Problem of E-Waste

The increasing demand for smartphones, laptops, and other electronics has led to shorter product lifespans and higher disposal rates. Improper handling of e-waste—such as landfilling or informal burning—releases toxic chemicals, contaminating soil and water. Effective recycling not only recovers precious metals but also prevents environmental pollution.

How Shredders Process E-Waste

1. Primary Size Reduction

E-waste shredders use high-torque, low-speed rotors with hardened steel blades to crush materials into smaller fragments. This step is crucial for:

-

Liberating embedded metals from plastics and ceramics.

-

Improving sorting efficiency for downstream processes.

2. Types of Shredders Used

-

Single-shaft shredders: Ideal for bulky items like printers and monitors.

-

Dual-shaft shredders: Provide finer shredding for circuit boards and hard drives.

-

Hammer mills: Further reduce shredded particles for metal extraction.

3. Challenges in E-Waste Shredding

-

Hard materials (e.g., aluminum frames, steel screws) can wear down blades.

-

Hazardous dust from crushed circuit boards requires proper filtration.

-

Plastics and insulation may require additional separation steps.

The Role of Shears in Metal Recovery

While shredders handle internal components, shears (such as alligator shears and hydraulic guillotine shears) are used to:

-

Cut open metal casings (e.g., smartphone bodies, laptop frames).

-

Separate mixed materials before shredding.

-

Prepare large metal pieces for smelting.

Advantages of Shearing Before Shredding

-

Reduces wear on shredders by removing hard metal parts.

-

Increases metal purity by minimizing cross-contamination.

-

Speeds up processing for high-volume recycling plants.

Advanced Sorting Technologies After Shredding

Once e-waste is shredded, advanced separation techniques recover valuable metals:

-

Magnetic Separation – Removes ferrous metals (iron, steel).

-

Eddy Current Separation – Extracts non-ferrous metals (aluminum, copper).

-

Air Classification – Separates lightweight plastics from heavy metals.

-

Electrostatic Separation – Isolates precious metals (gold, silver) from shredded PCBs.

Environmental and Economic Benefits

-

Metal Recovery: Recycling 1 ton of circuit boards can yield 40-800 times more gold than mining 1 ton of gold ore.

-

Energy Savings: Recycling aluminum uses 95% less energy than primary production.

-

Reduced Pollution: Proper e-waste processing prevents toxic leakage into ecosystems.

Future Trends in E-Waste Recycling

-

AI-Powered Sorting – Machine learning improves metal detection accuracy.

-

Modular Shredding Systems – Flexible configurations for different e-waste types.

-

Zero-Waste Initiatives – Closed-loop recycling for full material recovery.

Conclusion

Shredders and shears are indispensable in modern e-waste recycling, enabling efficient metal recovery while reducing environmental harm. As technology advances, smarter and more sustainable recycling methods will further enhance the industry’s ability to turn e-waste into valuable resources. Governments and manufacturers must invest in better recycling infrastructure to meet the growing challenge of electronic waste.