Introduction

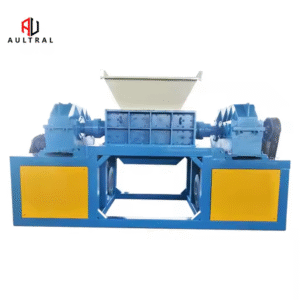

Shredders are essential equipment for processing solid waste such as scrap metal, plastics, wood, and rubber in recycling plants, waste treatment facilities, and industrial production lines. However, jamming and blockage are among the most frequent operational issues, leading to downtime, reduced efficiency, and potential machine damage.

This article explores the five most common causes of shredder jamming and provides practical solutions and preventive measures to help operators troubleshoot effectively and optimize performance.

1. Over-Sized or Over-Hard Materials

Problem Analysis

Shredders are designed for specific material sizes and hardness levels. Feeding oversized or excessively hard materials (e.g., thick metal blocks, high-strength alloys) can result in:

-

Sudden blade overload and motor strain

-

Materials getting stuck between shafts

-

Potential damage to bearings or gearboxes

Solutions

✅ Control Feed Size – Ensure materials do not exceed the shredder’s maximum input dimensions (e.g., single-shaft shredders typically accept lengths <50cm).

✅ Pre-Shredding – Use hydraulic shears or crushers for bulky/hard materials (e.g., engine blocks) before feeding them into the shredder.

✅ Select Proper Blades – Use Cr12MoV alloy steel blades for metals and SKD-11 blades for plastics/wood.

Prevention Tips

-

Install a vibrating screen or manual sorting platform to filter oversized materials.

-

Regularly inspect blade wear to avoid dull edges causing jams.

2. Tangling of Long Fibers or Flexible Materials

Problem Analysis

Materials like cables, tires, and woven bags can wrap around the rotor shafts, leading to:

-

Blades becoming entangled, losing cutting efficiency

-

Abnormal motor current spikes, triggering overload protection

-

Time-consuming post-jam cleanup

Solutions

✅ Use Hook Blades – Specially designed for fibrous materials to prevent wrapping.

✅ Install Anti-Wrapping Devices – Such as rotating combs or counter-rotating shafts to cut fibers during shredding.

✅ Pre-Cut Materials – Chop long cables into <1m segments or remove tire beads before shredding.

Prevention Tips

-

Add a metal detector to avoid copper wire entanglements in cables.

-

Apply anti-stick spray (e.g., silicone oil) for rubber/plastic materials.

3. Excessive or Uneven Feeding Speed

Problem Analysis

Overfeeding or inconsistent material input can cause:

-

Material pile-up in the crushing chamber

-

Motor load fluctuations, risking inverter burnout

-

Discharge chute clogging

Solutions

✅ Adjust Feed Rate – Use a variable-speed conveyor for consistent feeding (e.g., ≤0.5m/s for metal shredders).

✅ Install Level Sensors – Automatically pauses feeding when the chamber is full.

✅ Optimize Discharge System – Add a vibrating screen or auger conveyor to prevent output buildup.

Prevention Tips

-

Train operators to follow “small and frequent” feeding principles.

-

Regularly clean discharge areas to avoid residue accumulation.

4. Worn or Broken Blades

Problem Analysis

Blade degradation over time leads to:

-

Dull edges reducing cutting efficiency

-

Chipped blades causing shaft blockages

-

Increased blade gaps, crushing instead of shearing

Solutions

✅ Regular Blade Inspection – Check wear every 40-50 operating hours (replace if wear exceeds 5mm).

✅ Adjust Blade Gaps – Recommended: 0.5-1mm for metals, 2-3mm for plastics/wood.

✅ Upgrade to Harder Blades – Use D2 tool steel or tungsten carbide-coated blades for longevity.

Prevention Tips

-

Avoid processing high-impurity materials (e.g., sand in construction waste).

-

Manually rotate shafts during downtime to check for obstructions.

5. Hydraulic or Electrical Failures

Problem Analysis

Indirect causes of jamming include:

-

Hydraulic oil leaks → Low pressure, weak torque

-

Motor phase loss → Unstable rotation, material buildup

-

PLC errors → Mismatched feeding/shredding rhythm

Solutions

✅ Check Hydraulic Oil – Monitor levels and temperature (shut down if >60°C, replace filters).

✅ Test Motor Current – Investigate wiring or inverter issues if phase imbalance >10%.

✅ Reset PLC Settings – Restore factory defaults and recalibrate sensors.

Prevention Tips

-

Conduct monthly hydraulic pressure tests (match machine specifications).

-

Install temperature alarms to prevent motor overheating.

Summary: Quick Response Guide for Jamming Issues

| Issue | Immediate Action | Long-Term Fix |

|---|---|---|

| Oversized Material | Remove blockage manually | Install screening equipment |

| Fiber Tangling | Reverse rotation to unwind | Use anti-wrapping blades |

| Overfeeding | Reduce conveyor speed | Add level sensors |

| Blade Wear | Replace/Sharpen blades | Regular gap checks |

| System Failure | Inspect hydraulics/electrics | Scheduled maintenance |

Conclusion

Shredder jams should be addressed through preventive measures rather than reactive fixes. Key recommendations:

-

Implement SOPs (Standard Operating Procedures) for operators.

-

Adopt IoT monitoring for real-time data (vibration, temperature, current).

-

Collaborate with suppliers for custom blade/feeding solutions.