🏭 Horizontal vs. Vertical Balers for Aluminum Cans:

A Complete Guide to Choosing the Right Baling Solution

Recycling aluminum cans is not only an environmentally responsible practice, but also a profitable one. To maximize the efficiency of this process, having the right baler is essential.

The two most common types of balers for aluminum cans are vertical balers and horizontal balers. While both can compress aluminum into dense, manageable bales, they differ significantly in terms of efficiency, cost, space requirements, and automation level.

In this article, we’ll take a deep dive into both machines, comparing their pros and cons in aluminum can recycling applications.

🧱 What Is a Vertical Baler?

A vertical baler compresses material using a vertically descending ram. It is manually loaded from the front, and typically used for low-to-medium volumes of recyclable material.

✅ Pros of Vertical Balers for Aluminum Cans:

✅ Pros of Vertical Balers for Aluminum Cans:

-

Lower Initial Investment

Ideal for businesses on a budget — much cheaper than horizontal models. -

Space-Saving Design

Compact structure suits small workshops, retail stores, and small recycling centers. -

Energy-Efficient

Equipped with lower-power motors, helping reduce electricity consumption. -

Simple Installation & Maintenance

Fewer moving parts and no conveyor system required.

❌ Cons of Vertical Balers:

❌ Cons of Vertical Balers:

- Limited Automation

Most vertical balers require manual material feeding and bale strapping, which can slow down processing speed and increase labor intensity — especially in higher-volume operations. -

Lower Throughput

Best suited for facilities with limited daily volumes of cans (e.g., under 500 kg/day). -

Smaller Bale Size

Smaller bales may increase transportation frequency and costs.

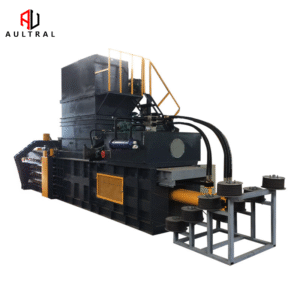

🏗️ What Is a Horizontal Baler?

A horizontal baler compresses materials using a horizontal ram and is typically fed via a conveyor or hopper. It is built for medium-to-high volumes and is often used in industrial recycling operations.

✅ Pros of Horizontal Balers for Aluminum Cans:

✅ Pros of Horizontal Balers for Aluminum Cans:

-

High Productivity

Continuous feeding and faster cycle times dramatically boost output. -

Automation-Ready

Supports automatic tying, bale ejection, and feeding — ideal for reducing labor costs. -

Larger, Denser Bales

Produces uniform bales with higher density, saving on storage and transportation. -

Integration Capability

Easily connects to shredders, sorters, and conveyors for streamlined production lines.

❌ Cons of Horizontal Balers:

❌ Cons of Horizontal Balers:

-

Higher Capital Cost

Significant upfront investment compared to vertical balers. -

Larger Footprint

Requires more space and may involve foundation work. -

More Complex Maintenance

More components = more maintenance and possible downtime if not managed properly.

🔍 Side-by-Side Comparison Table

| Feature | Vertical Baler | Horizontal Baler |

|---|---|---|

| Cost | Low | High |

| Space Requirement | Small | Large |

| Bale Size | Small/Medium | Large/Dense |

| Feeding Method | Manual | Automatic or Conveyor |

| Best for | Low to Medium Volume | Medium to High Volume |

| Automation | Minimal | High (fully or semi-auto available) |

| Labor Involvement | High | Low |

🏁 Final Thoughts: Which One Should You Choose?

Your decision depends on your daily volume, available space, budget, and future plans:

-

🟢 Choose a Vertical Baler if:

-

You process under 500–1000 kg of cans daily

-

You operate in a smaller space

-

You prefer a low-cost solution with manual control

-

-

🔵 Choose a Horizontal Baler if:

-

You run a recycling plant or large-scale facility

-

You want automated operation and high throughput

-

You need heavier, more transport-efficient bales

-

💬 Need Expert Advice?

At Shanghai Aultral Machinery Co., Ltd., we specialize in both vertical and horizontal balers for aluminum, plastics, cardboard, and more. Our engineers will help you choose the right machine for your material, space, and capacity.

📩 Contact us today for a tailored solution, machine videos, and a competitive quotation!