🌍 Introduction: A Shredding Solution for a Sustainable Future

As global environmental awareness continues to grow, industries around the world are under increasing pressure to manage waste more responsibly. Efficient recycling has become a top priority, and at the center of this movement stands a powerful piece of equipment: the double-shaft shredder.

Designed to tackle a wide range of materials with precision and durability, double shaft shredders are becoming essential tools across recycling, waste management, and resource recovery operations.

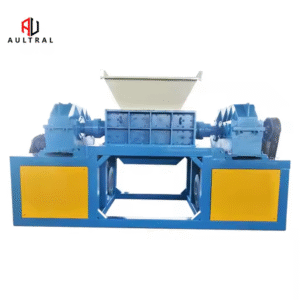

🔧 What Is a Double Shaft Shredder?

A double shaft shredder is an industrial-grade machine equipped with two parallel shafts that rotate at low speeds and high torque. The interlocking blades tear, shear, and crush materials into smaller pieces. Unlike high-speed crushers, these machines prioritize powerful torque and controlled output, making them ideal for tough and variable waste.

♻️ Key Recycling Applications

Double shaft shredders are known for their versatile processing capabilities, making them suitable for recycling many different types of waste:

🔹 1. Plastic Waste

-

PET bottles, plastic drums, film rolls, PVC pipes

-

Car bumpers, plastic pallets, and injection-molded products

🔹 2. Scrap Metal

-

Aluminum profiles, copper wires, steel shavings

-

Electric appliance casings, engine parts

🔹 3. Rubber Materials

-

Used car tires, rubber soles, conveyor belts

🔹 4. Electronic Waste (E-waste)

-

Circuit boards, batteries, hard drives, printer parts

🔹 5. Wood and Biomass

-

Pallets, logs, branches, furniture scrap

🔹 6. Textiles and Clothes

-

Cotton, synthetic fabrics, carpet offcuts

🔹 7. Paper and Cardboard

-

Confidential documents, old books, and packaging cardboard

🔹 8. Municipal Solid Waste (MSW)

-

Household waste, kitchen leftovers, organic material

Whether for pre-treatment before further separation or for volume reduction, the double shaft shredder performs reliably across all these materials.

🛠 Functional Advantages

Why are double-shaft shredders so favored in the recycling industry? Here are some of their standout features:

✅ Robust Cutting System

-

Hardened alloy steel blades offer long service life

-

Intermeshing teeth ensure consistent shredding

✅ Intelligent Control System

-

PLC-based control with automatic reverse rotation in case of overload

-

Customizable speed and torque to suit different materials

✅ Uniform Output

-

Adjustable blade spacing allows for controlled particle size, preparing materials for downstream processes (washing, granulating, compacting)

✅ High Safety Standards

-

Enclosed structure, emergency stop system, and automatic shutoff on jams for operator safety

✅ Easy Maintenance

-

Modular blade systems and quick-change design ensure minimum downtime

🌱 Impact on the Recycling Industry

The widespread adoption of double-shaft shredders has brought about significant improvements in recycling operations:

🔄 Driving the Circular Economy

By efficiently reducing complex waste into reusable fragments, double shaft shredders help turn waste into valuable secondary raw materials.

⏱ Increasing Efficiency

With high throughput and reliable operation, they allow facilities to handle larger volumes of waste faster and more consistently.

💰 Reducing Operational Costs

Lower maintenance needs and energy-efficient motors result in reduced total cost of ownership.

🌎 Supporting Environmental Goals

By enabling more effective waste recovery, they contribute to reduced landfill use, lower emissions, and resource conservation.

📌 Conclusion: A Must-Have for Modern Recycling

Whether you’re processing plastic, metal, rubber, or mixed municipal waste, the double shaft shredder proves to be a high-value investment. Its reliability, adaptability, and durability make it an essential part of any modern recycling or waste management operation.

If your business is looking to maximize material recovery, improve production efficiency, and contribute to a greener planet, the double shaft shredder is the right tool for the job.