Introduction To Plastic Shredder Production Line

In today’s fast-paced manufacturing and recycling industry, plastic waste management has become more critical than ever. A Plastic Shredder Production Line is a comprehensive system designed to process various types of plastic materials into smaller, manageable pieces. These shredded materials can then be recycled or repurposed for further production. By automating the shredding process, businesses can achieve higher efficiency, reduce labor costs, and contribute to sustainable environmental practices.

What Is A Plastic Shredder Production Line?

-

Plastic Shredder Machine: The core of the production line, designed to cut large plastic objects into smaller pieces.

-

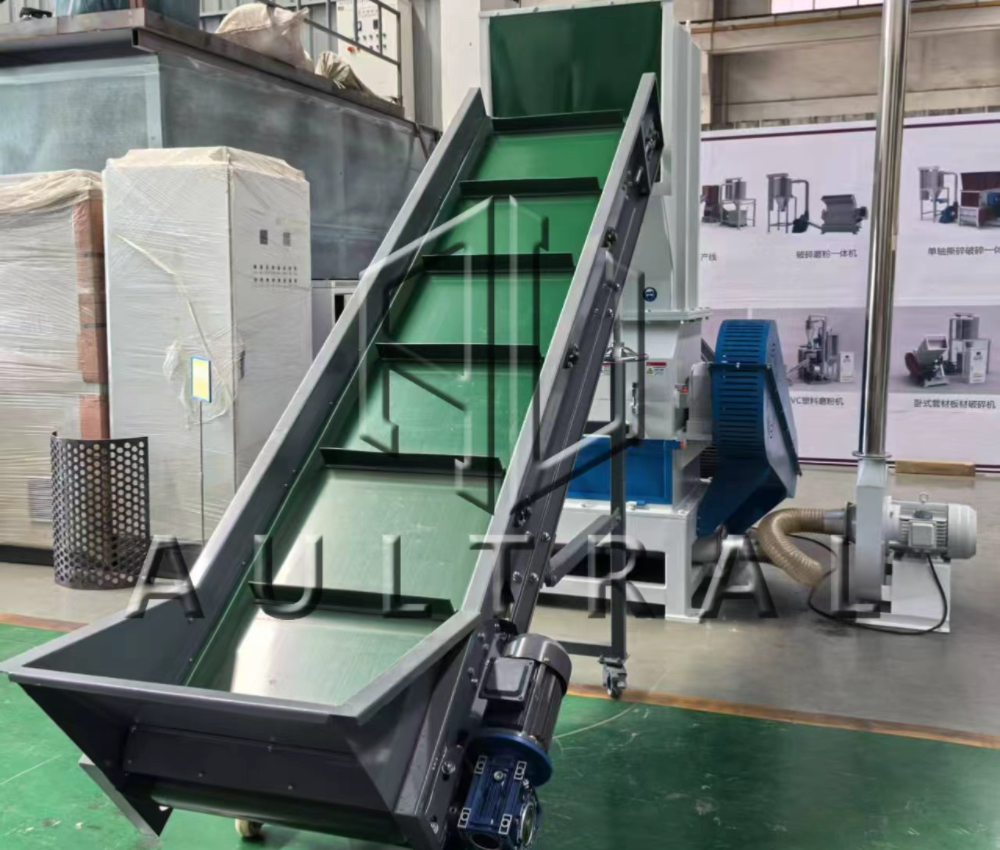

Conveyor System: Transports materials efficiently between different stages of the process.

-

Magnetic Separator: Removes metal contaminants from the plastic waste to ensure pure shredding.

-

Dust Collector: Maintains a clean working environment by reducing airborne particles.

-

Control Panel: Allows operators to manage the entire production line safely and efficiently.

The production line can handle a wide range of plastic materials, including PET bottles, HDPE containers, PVC pipes, PP sheets, and other industrial plastics. Depending on the design, it can operate continuously or in batches, making it suitable for different production needs.

Why Use A Plastic Shredder Production Line?

Using a plastic shredder production line offers several key benefits for businesses and the environment:

1. Efficient Waste Reduction

Plastic materials can occupy large volumes of space in warehouses or landfills. By shredding these materials, the volume is significantly reduced, making storage and transportation more manageable.

2. Cost-Effective Recycling

Shredded plastics can be sold to recycling companies or reused in manufacturing new products. This reduces the need for virgin plastic and lowers production costs, providing a tangible economic benefit.

3. Environmental Protection

Recycling plastic helps reduce environmental pollution. A plastic shredder production line ensures that plastic waste is properly processed and repurposed, minimizing the negative impact on ecosystems.

4. Versatile Applications

Plastic shredders can handle a variety of plastics, including hard and soft types. They are ideal for industrial, commercial, and household plastic waste management, making them highly versatile.

How Does A Plastic Shredder Production Line Work?

Operating a plastic shredder production line involves several key steps, which are simple when the system is properly installed:

1. Material Feeding

Plastic materials are loaded into the feeding hopper, either manually or through an automatic conveyor system. Uniform feeding ensures the shredder operates smoothly.

2. Shredding Process

The shredder machine uses rotating blades to cut plastic materials into smaller pieces. The size of the shredded pieces can be adjusted by changing the screen size or blade configuration.

3. Sorting And Separation

After shredding, materials may contain unwanted elements such as metal or dust. A magnetic separator removes metallic contaminants, while a dust collector ensures a clean working environment.

4. Transport And Collection

Shredded plastics are transported via conveyor systems to storage bins or directly to the next processing stage, such as washing, drying, or granulating.

5. Final Output

The shredded plastic is ready for recycling, extrusion, or other industrial applications. The final product can be customized according to size, shape, and material type.

Key Considerations When Using A Plastic Shredder Production Line

To maximize efficiency and safety, consider the following points:

-

Material Compatibility: Ensure the shredder is suitable for the type and hardness of plastic being processed.

-

Maintenance: Regular maintenance of blades, motors, and conveyors prolongs equipment life.

-

Safety Measures: Operators should follow safety guidelines and use protective equipment.

-

Energy Consumption: Choose energy-efficient systems to reduce operational costs.

-

Automation Level: Depending on production needs, select fully automatic, semi-automatic, or manual lines.

Applications Of Plastic Shredder Production Lines

Plastic shredder production lines are widely used across different industries, including:

-

Recycling Plants: Transforming post-consumer plastic waste into reusable materials.

-

Manufacturing Industry: Producing plastic granules or powders for new products.

-

Waste Management Companies: Reducing landfill burden by processing plastic waste efficiently.

-

Construction Projects: Recycling plastic pipes, panels, and packaging materials.

Advantages Of Implementing A Plastic Shredder Production Line

Implementing a production line offers multiple advantages:

-

High Productivity: Can process hundreds of kilograms of plastic per hour.

-

Consistent Output: Ensures uniform size and quality of shredded material.

-

Reduced Labor Costs: Automated systems require fewer operators.

-

Environmental Compliance: Meets industry standards for waste management and recycling.

-

Customizable Design: Can be tailored to specific material types and production capacities.

Advanced Features Of Modern Plastic Shredder Production Lines

Modern plastic shredder production lines come with a variety of advanced features that enhance productivity and ease of operation. Many systems now include automatic feeding systems, which reduce manual labor and ensure consistent input. Intelligent control panels allow operators to monitor motor performance, blade wear, and operational speed in real time. Some lines are equipped with safety interlocks and emergency stop mechanisms to prevent accidents. Additionally, energy-saving motors and variable frequency drives help reduce power consumption while maintaining high efficiency.

Tips For Maximizing Shredder Performance

To get the best performance from a plastic shredder production line, follow these practical tips:

-

Regular Blade Inspection: Ensure blades are sharp and replace them when necessary to maintain shredding efficiency.

-

Avoid Overloading: Do not feed more material than the machine is designed to handle. Overloading can cause jams and damage the motor.

-

Clean The System Frequently: Removing dust and residues prevents clogging and ensures smooth operation.

-

Train Operators Properly: Skilled operators understand machine limitations and safety protocols, improving both efficiency and safety.

Future Trends In Plastic Shredder Production

The plastic recycling industry is constantly evolving. Smart production lines with IoT integration allow remote monitoring and predictive maintenance, reducing downtime. Eco-friendly technologies are being developed to minimize energy use and environmental impact. The demand for recycled plastic products is increasing globally, making plastic shredder production lines an essential part of sustainable manufacturing and recycling solutions.

Final Thoughts

Investing in a Plastic Shredder Production Line is no longer just a choice but a strategic necessity. It transforms waste into valuable resources, reduces environmental footprint, and provides significant cost savings. With the right system, proper maintenance, and trained operators, companies can achieve high efficiency, safety, and sustainability in plastic waste management.

Conclusion

A Plastic Shredder Production Line is an essential investment for businesses aiming to optimize plastic waste management. It not only improves efficiency and reduces costs but also supports sustainable practices by minimizing environmental impact. Whether you are in recycling, manufacturing, or waste management, investing in a reliable production line ensures a steady supply of shredded plastics for various applications.By understanding what a plastic shredder production line is, why it is needed, and how to operate it effectively, businesses can enhance productivity, protect the environment, and achieve long-term operational success.