Maximizing Efficiency in Scrap Management: The Power of Metal Horizontal Balers

In the fast-paced world of metal recycling and manufacturing, efficiency, space optimization, and cost control are top priorities.

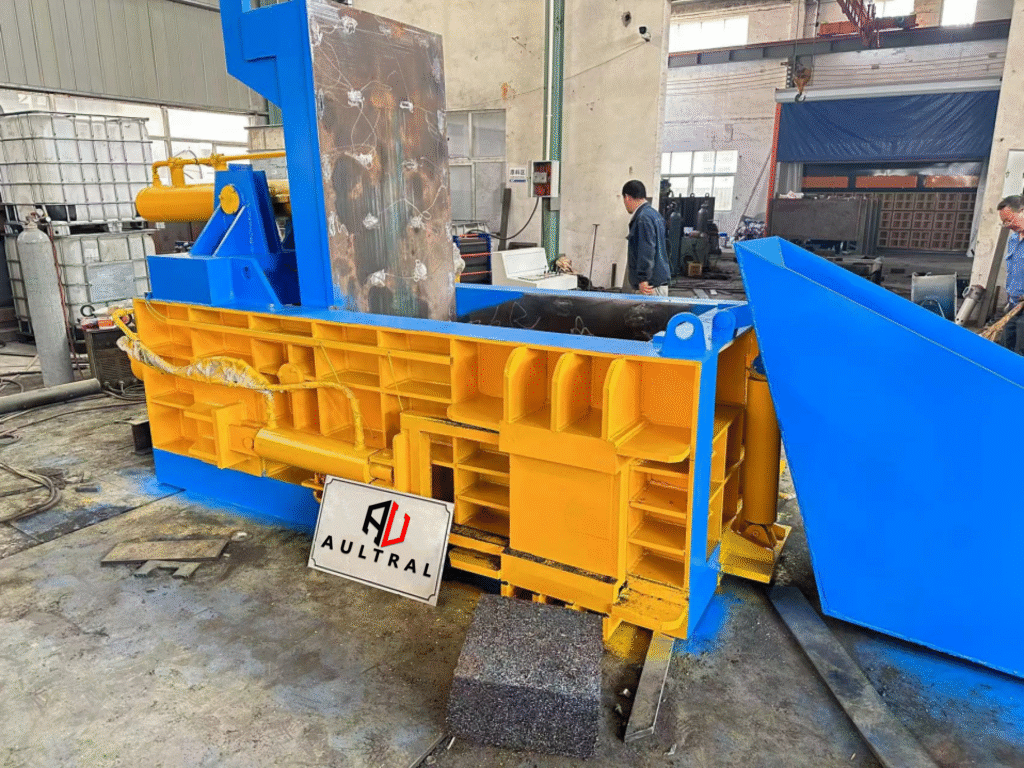

One piece of equipment that continues to transform scrap handling operations worldwide is the metal horizontal baler.

Designed to compress large volumes of scrap metal into dense, uniform bales, this machine offers both operational and economic advantages for businesses of all sizes.

What is a Metal Horizontal Baler?

Metal Horizontal Baler is an industrial machine that uses hydraulic pressure to compress metal waste.

such as steel sheets, aluminum profiles, copper wires, or mixed scrap—into compact bales.

TUnlike vertical balers, horizontal balers process material on a horizontal axis, enabling faster feeding, higher throughput, and automated operation.

Key Benefits

-

High Output & Continuous Feeding

This is an Horizontal balers are ideal for high-volume operations thanks to conveyor feeding or crane loading systems. They can handle a constant flow of scrap without frequent stops. -

Labor Cost Reduction

Automation minimizes the need for manual intervention, reducing labor costs and improving workplace safety. -

Space Optimization

By compressing loose scrap into dense bales, businesses can save up to 80% in storage space and reduce transportation costs. -

Better Material Value

Uniform bales are easier to transport, stack, and sell, and they meet the size requirements of most smelters and recycling facilities.

Applications

Scrap Yards: For processing mixed ferrous and non-ferrous metals.

Metal Fabrication Shops: For collecting offcuts, punchings, and waste sheets.

Automotive Recycling: For compressing car body panels, engines, and metal parts.

Manufacturing Plants: For managing production scrap efficiently.

Why Choose a Horizontal Baler Over a Vertical Baler?

While vertical balers are suitable for lower volumes and smaller facilities, horizontal balers are the go-to choice for continuous, high-capacity processing.

They offer faster cycle times, higher bale densities, and greater automation potential—making them perfect for large-scale scrap operations.

Environmental Impact

Investing in a metal horizontal baler isn’t just about profit—it’s about sustainability.

Metal Horizontal Baler. By enabling more efficient recycling, these machines reduce landfill waste, conserve raw materials, and lower CO₂ emissions from transportation.

Conclusion

Whether you run a recycling center, manufacturing plant, or large-scale scrap yard, a metal horizontal baler can dramatically improve your efficiency, profitability, and environmental footprint.

By turning loose scrap into valuable, manageable bales, you’ll not only streamline your operations but also strengthen your position in the competitive metal recycling industry.